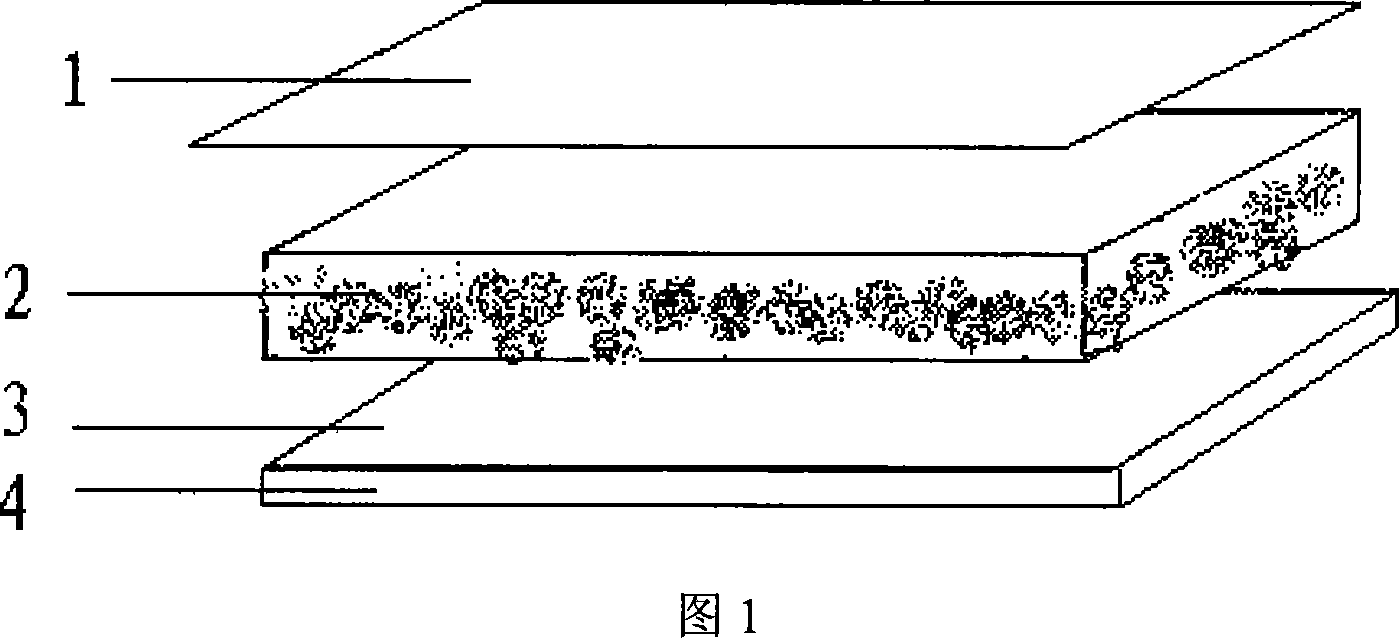

Composite phenolic aldehyde building energy-saving heat-insulating board and its manufacturing method and application

A technology for building energy conservation and manufacturing methods, which is applied in building structure, construction, chemical instruments and methods, etc., can solve the problems of complicated construction procedures, long construction period, poor adhesiveness, etc., and achieves good thermal insulation performance and thermal insulation. Good thermal effect and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the calcium silicate plate that 3mm is thick enters in the baking oven of 80 ℃ earlier as inorganic material composite plate and preheats, carries out brushing phenolic polyurethane adhesive after preheating, will press certain ratio (phenolic resin: Surfactant: foaming agent: toughening agent: curing agent=100:1:8:5:10) the phenolic resin foaming composition (guaranteeing that the thickness of phenolic foam is 20mm) is poured on it, and with it as protection The aluminum foil paper on the surface layer enters the composite insulation board continuous production line together for foaming and curing (note: when entering the production line for foaming and curing, a layer of plastic film must be placed under the calcium silicate board to prevent the combination material and foam from leaking out), and finally according to the specifications Composite panels are required to be cut to a certain length and trimmed for packaging. This product is used in roof ins...

Embodiment 2

[0027] Embodiment 2: the 5mm thick glass magnesium board is entered in the baking oven of 80 ℃ earlier as inorganic material composite board and preheated, after preheating, carry out brushing phenolic polyurethane adhesive, after gluing, will press certain ratio (phenolic resin: surface Active agent: foaming agent: toughening agent: curing agent = 100:2:1:8:10) the phenolic resin foaming composition (guaranteed that the thickness of phenolic foam is 40mm) is poured on it, and with it as the protective surface Layers of aluminum foil paper enter the composite insulation board continuous production line together for foaming and curing (note: when entering the production line for foaming and curing, a layer of plastic film must be placed under the glass magnesium board to prevent the combination material and foam from leaking out), and finally cut according to the specifications Composite panels cut to length and trimmed for packaging. This product is used in roof insulation, an...

Embodiment 3

[0029]Embodiment 3: the 8mm thick magnesite board is entered in the baking oven of 80 ℃ earlier as inorganic material composite board and is preheated, after preheating, carry out brushing phenolic polyurethane adhesive, after gluing, will press certain ratio (phenolic resin: surface Active agent: foaming agent: toughening agent: curing agent = 100:3:6:7:12) the compounded phenolic resin foaming composition (to ensure that the thickness of the phenolic foam is 60mm) is poured on it, and it is used as a protective surface Layers of aluminum foil paper enter the composite insulation board continuous production line together for foaming and curing (note: when entering the production line for foaming and curing, a layer of plastic film must be placed under the magnesite board to prevent the combination material and foam from leaking out), and finally cut according to the specifications. Composite panels cut to length and trimmed for packaging. This product is used in roof insulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com