Epoxy ester wastewater recycling treatment method

A treatment method and epoxy ester technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Energy consumption, guaranteed treatment effect, convenient filler replacement and equipment maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

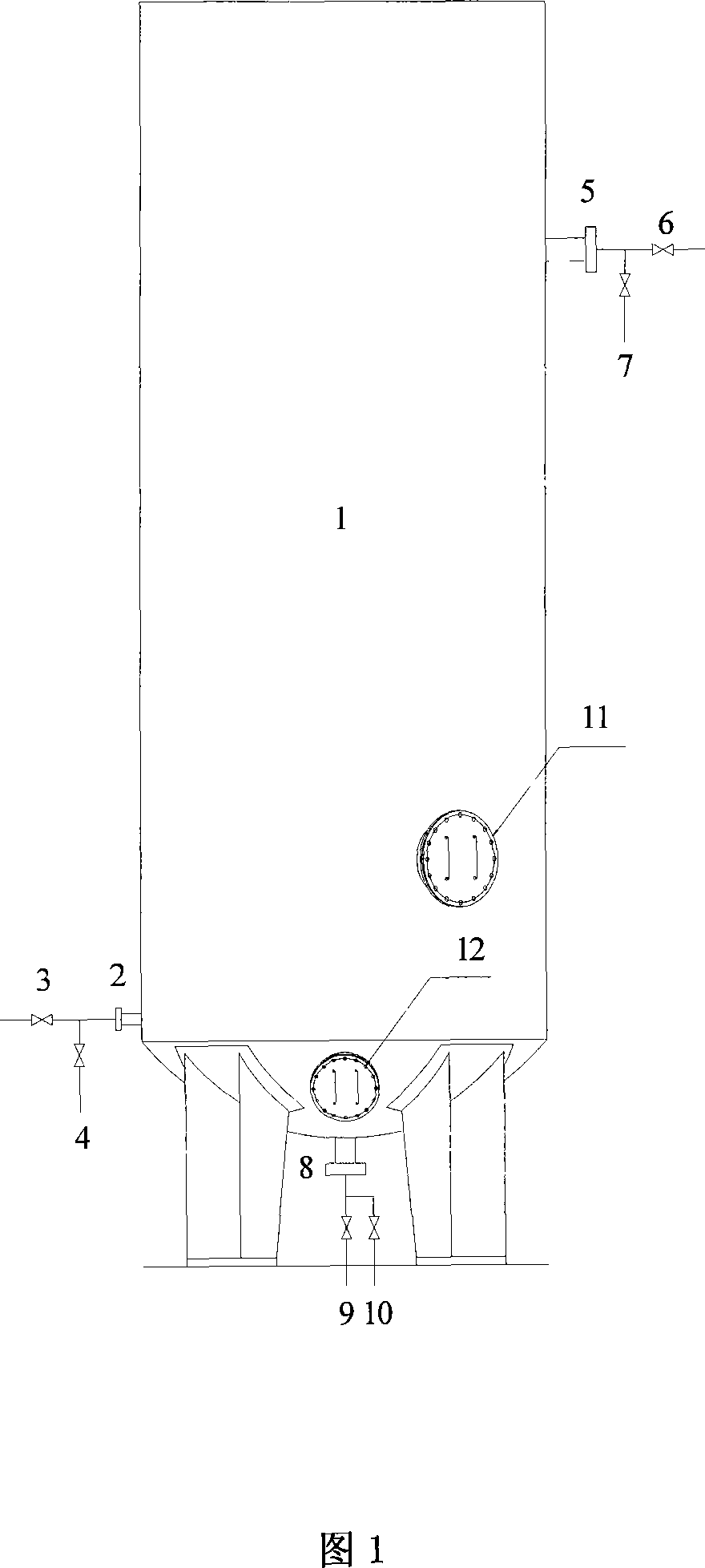

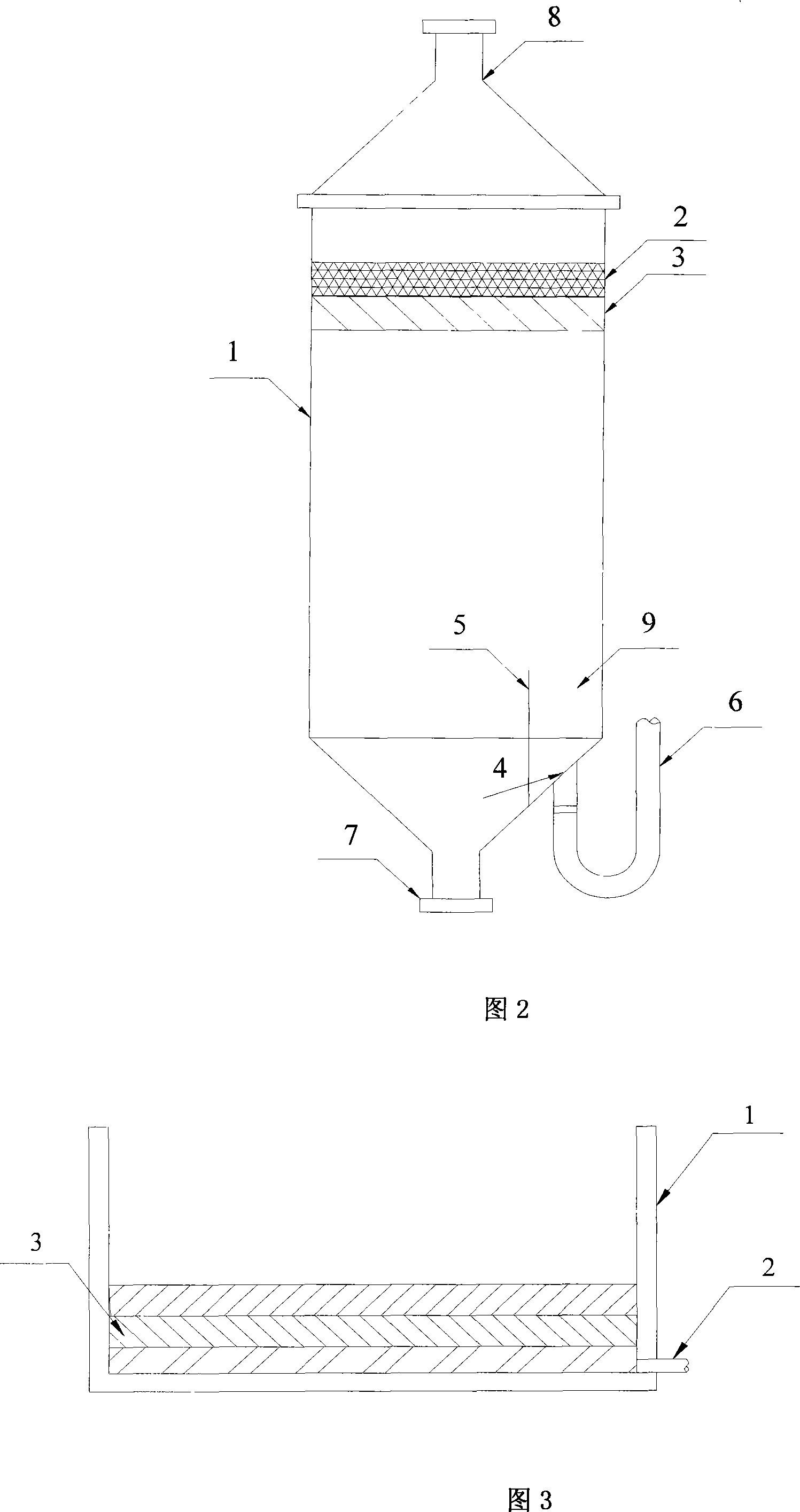

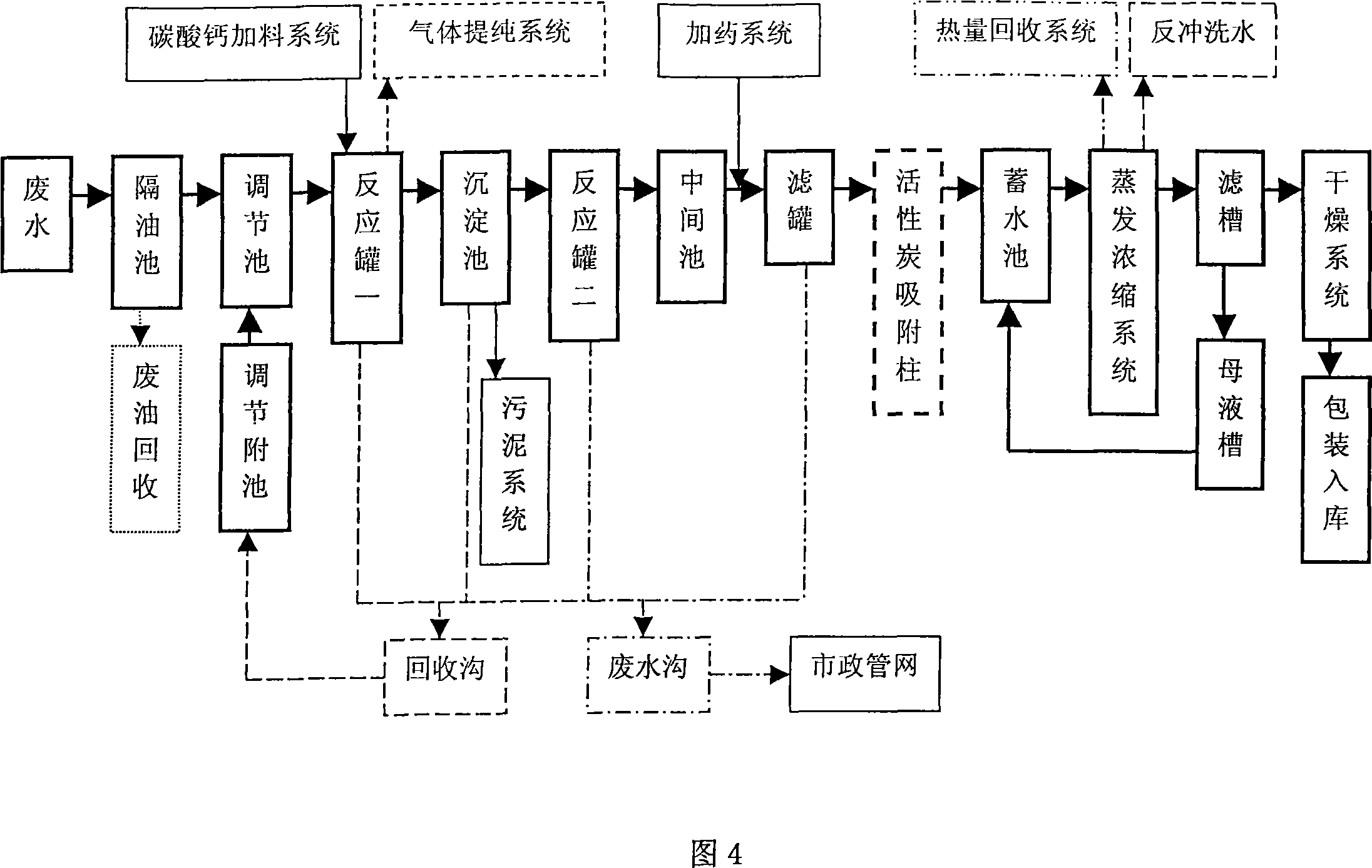

[0052] The present invention will be further described below in conjunction with drawings and embodiments.

[0053] The water quality of formic acid wastewater generally from the production of epoxidized soybean oil is shown in Table 1.

[0054] Table 1 Water quality of formic acid wastewater

[0055] Substance name

concentration

formic acid

2~20%

0.2~2.0%

100~5000mg / L

COD Cr

10000~300000mg / L

pH

2~4

color

Colorless ~ dark gray

[0056] Implementation Step 1: Oil Separation

[0057] Formic acid wastewater from epoxy soybean oil production first enters the grease trap. After water distribution and aeration, more than 99% of the oil in the wastewater floats to the surface, collects in the grease trap, and then flows into the recovery oil drum. The formic acid water in the lower layer is sent to the regulating tank through the automatic drainage device. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com