Rice husk rapid charring method and carbonization furnace

A technology of rice husk charcoal and carbonization furnace, which is applied in coking ovens, special forms of dry distillation, petroleum industry, etc. It can solve the problems of promotion and development constraints, high loss rate of charcoal burning, and increase of charcoal production costs, etc., to expand the market application space , easy operation, and improved quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

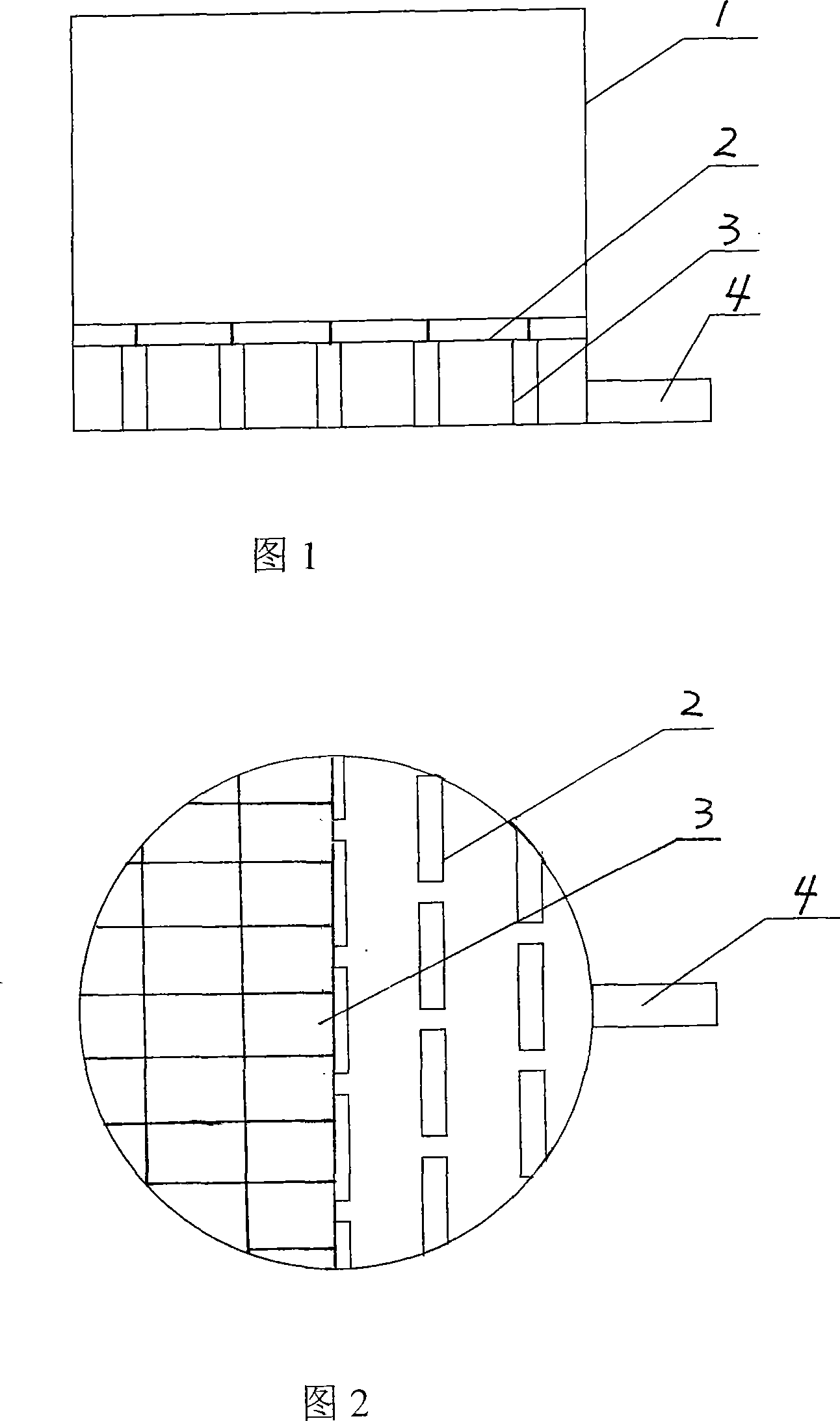

[0017] As shown in Figure 1, the furnace body 1 of the carbonization furnace of the present invention is an open cylinder, and several rows of vertical bricks 2 are arranged at the bottom of the furnace. A layer of refractory bricks 3 is tiled above the bricks, and the gap between the refractory bricks is the air induction channel, and the air induction pipe 4 is arranged below the furnace body to communicate with the induced draft fan. The optimum diameter of the furnace body is 1750-1800mm, and the height is about 1100mm. The carbonization time of each furnace for a 0.5 ton carbonization furnace only takes 4-5 hours.

[0018] Spread a layer of rice husk with a thickness of 15-20cm on the bottom of the carbonization furnace, put a layer of dry straw with a thickness of 2-3cm on the rice husk as the ignition material, and ignite the ignition material at multiple points to make the surface of the rice husk uniform Combustion, at this time, turn on the induced draft fan to start...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com