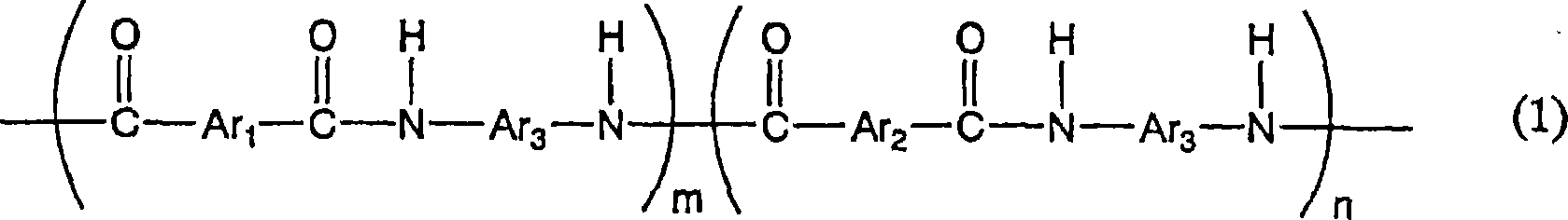

Polyamide resin, epoxy resin compositions, and cured articles thereof

A technology of epoxy resin and aromatic polyamide, which is applied to polyamide resin, can solve the problems such as the reduction of electrical characteristics, and achieve the effect of improving adhesiveness, excellent electrical characteristics, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

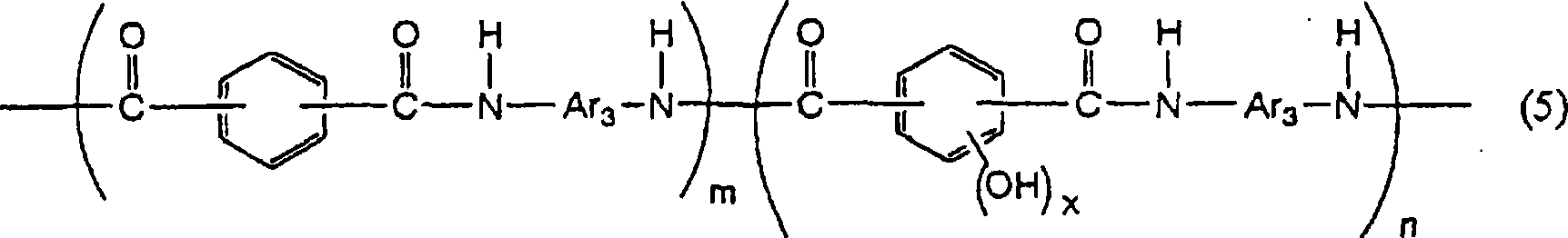

[0091] Nitrogen replacement was carried out in a flask with a thermometer, a condenser, and a stirrer, and 1.8 g of 5-hydroxyisophthalic acid, 81.3 g of isophthalic acid, 102 g of 3,4'-diaminodiphenyl ether, and chlorinated Lithium 3.4g, N-methylpyrrolidone 344g, pyridine 115.7g, after stirring and dissolving, add triphenyl phosphite 251g, react at 90 ℃ for 8 hours, promptly obtain containing the present invention shown in following formula (6): A reaction solution of a phenolic hydroxyl group-containing aromatic polyamide resin (A).

[0092]

[0093] (n / (n+m)=0.022 in formula (6)). After cooling the reaction solution to room temperature, it was poured into 500 g of methanol to precipitate the produced polyamide resin. The precipitated resin was separated by filtration, washed with 500 g of methanol, and then purified by reflux of methanol. Thereafter, after cooling the reflux liquid to room temperature, the resin was separated by filtration and dried to obtain a resin pow...

Embodiment 2

[0095] Except that 102 g of 3,4'-diaminodiphenyl ether in Example 1 was changed to 102 g of 4,4'-diaminodiphenyl ether, other operations were performed in the same manner as in Example 1 to obtain the compound containing the following formula (7). The reaction liquid of the aromatic polyamide resin (B) containing phenolic hydroxyl group of the present invention shown,

[0096]

[0097] (n / (m+n)=0.022 in formula (7)). And this reaction liquid was processed similarly to Example 1, and obtained resin powder (B). The obtained amount was 158 g, and the yield was 94%. 0.100 g of this resin powder (B) was dissolved in 20.0 ml of N,N-dimethylacetamide, and its intrinsic viscosity was measured at 30° C. using an Oswald viscometer to be 0.65 dl / g. The calculated value of active hydrogen equivalent with respect to an epoxy group was 3300 g / eq. Both ends of the obtained polyamide resin of the present invention were amino groups, and the average degree of polymerization (theoretical ...

Embodiment 3

[0099] 100 g of the reaction solution obtained in Example 1 was maintained at 90° C., 30 g of ion-exchanged water was added, and the resin was precipitated by cooling to 60° C. or lower. After removing the upper phase, 40 g of N,N-dimethylformamide was added and stirred at 60° C. for 30 minutes to dissolve uniformly, and then 30 g of ion-exchanged water was added to precipitate a resin. The precipitation and dissolution operation of the resin was repeated five times to obtain a resin solution, and then the moisture in the resin solution was removed under a reduced pressure of 0.02 MPa to obtain 75 g of the resin composition of the present invention having a resin concentration of 20% by weight. Take 1.00 ml of the resin composition of the present invention, and use an E-type rotational viscometer at 25° C. to measure its rotational viscosity to be 200 mPa·s.

[0100] In addition, 50 g of the resin composition of the present invention was poured into 50 g of methanol, and the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| logarithmic viscosity | aaaaa | aaaaa |

| logarithmic viscosity | aaaaa | aaaaa |

| logarithmic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com