Technique for processing black series fresh water pearl

A freshwater pearl and processing technology, applied in jewelry, clothing, organic dyes, etc., can solve the problems of cobalt salt toxicity, cobalt element exceeding the standard, pearl blackening, etc., and achieve the effect of no spots on the surface, strong durability and beautiful color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

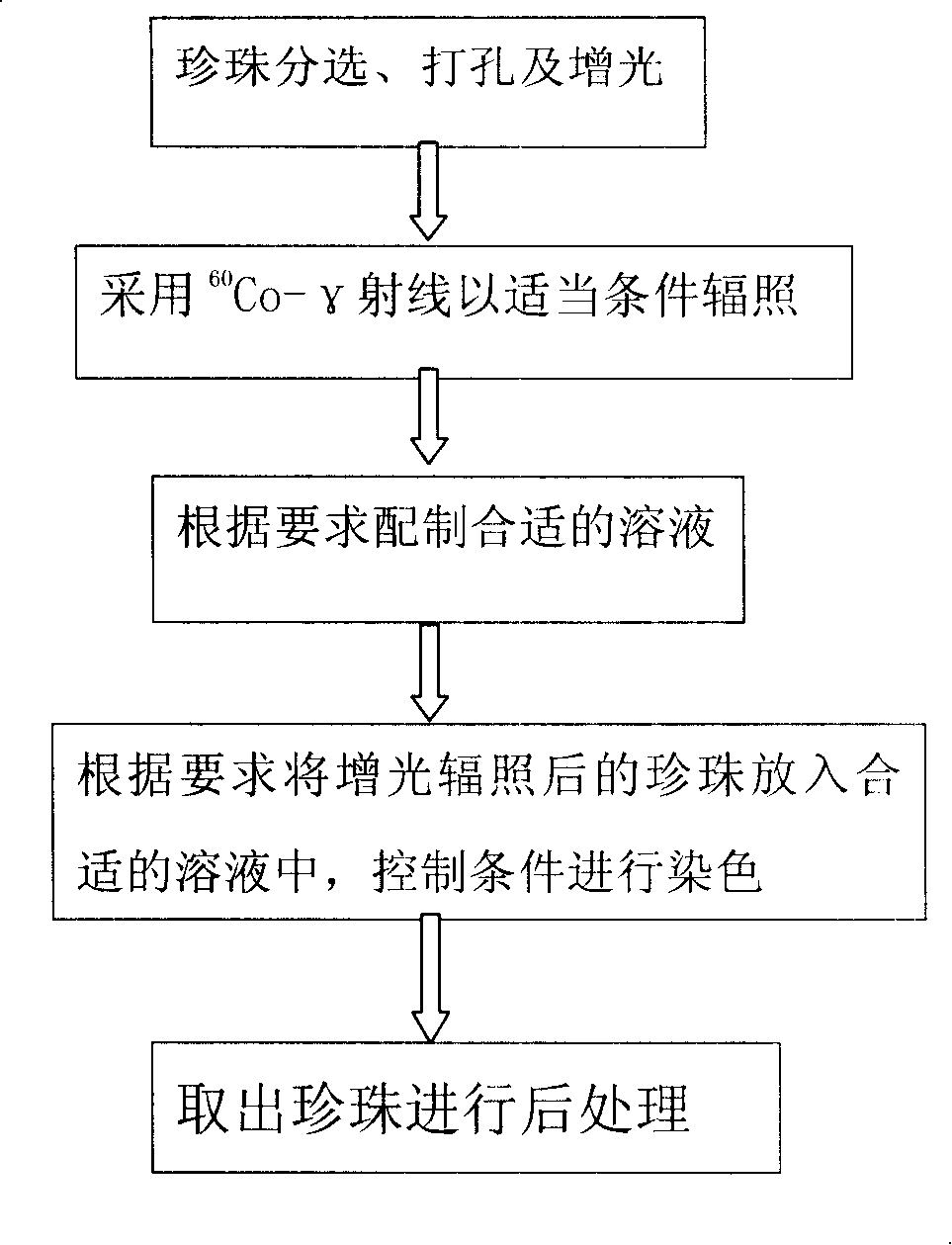

Method used

Image

Examples

Embodiment 1

[0032] Taken after being enhanced by 60 Co-γ-ray irradiation (irradiation dose of 600,000 roentgens / min, irradiation for 20 hours) is basically blue-gray pearl samples to be treated with malachite green overtones. Wash and let dry for 24 hours before staining.

[0033] Slowly add 25% (w / w) NH to a clean glass bottle containing 100 mL of 2% (w / w) silver nitrate (prepared in purified water) solution 3 ·H 2 020mL, add ammonium nitrate to adjust the pH=9.8∽10.4, then add 20mL of the compound of ethylene glycol methyl ether and ethanol with a volume ratio of 1:9, stir the solution evenly and put it into the pearls to be dyed, the bath ratio is 1:2, Place in a box with a constant temperature of 58°C and irradiated with a fluorescent lamp. Take it out after 25 days. Wash the pearls with pure water, put them in a petroleum ether solution containing 1% (w / w) methyl mercaptan, place them at low temperature (not exceeding 10°C) for about 1 hour, take them out, wash them, dry them and...

Embodiment 2

[0035] Take pearl samples that are basically bluish-gray and are to be treated with malachite green overtones after being irradiated by 60Co-γ rays (irradiation dose of 700,000 roentgens / min for 20 hours) after brightening. Wash and let dry for 24 hours before staining.

[0036] 2% AgNO in 100ml 3 Add 20ml of 25% ammonia water, 20ml of a mixture of ethanol and ethylene glycol with a volume ratio of 9:1, stir to mix evenly, add 2mL of nano-titanium dioxide sol, and place it in a constant temperature water bath at 60-70°C for three days until the color changes to silver-purple Finally, transfer the dyeing system to a box with a constant temperature of 58°C and irradiated by fluorescent lamps, take it out after 5 to 8 days, take out the pearls after the dyeing solution is cooled, wash them immediately, and put them in a container of benzotriazole prepared by pure water. In the container of the post-treatment agent of the aqueous solution with a fraction of 5% and ATFIN AGS PLUS (s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com