Method for preparing ethylene sulfite

A technology of vinyl sulfite and ethylene oxide, applied in the field of catalytic synthesis of vinyl sulfite, to achieve the effect of improving purity and yield and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

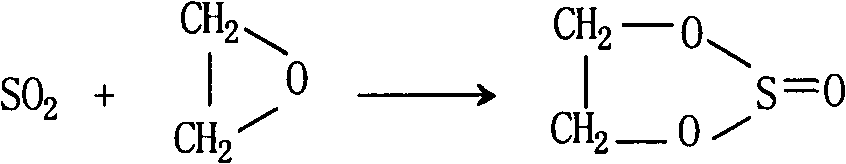

[0008] The preparation method of vinyl sulfite of the present invention comprises carrying out contact reaction of sulfur dioxide and ethylene oxide under the condition that the complex compound of polyethylene glycol (PEG) and metal halide is used as a catalyst. The reaction is shown in the following formula.

[0009]

[0010] The usage amount of the catalyst can be 0.01-0.5 times, preferably 0.05-0.2 times of the weight of ethylene oxide.

[0011] Polyethylene glycol (PEG) has the effect of complexing alkali metal and alkaline earth metal ions, thereby improving the catalytic ability of negative ions. The catalyst used in the present invention can be a complex formed by polyethylene glycol (PEG) and metal halide, wherein the molar ratio of polyethylene glycol (PEG) to metal halide is (1.0-4.0): 1 . The molecular weight range of the polyethylene glycol (PEG) may be 190-880. The metal halide may be an alkali metal halide and / or an alkaline earth metal halide, preferably ...

Embodiment 1

[0016] In 200 milliliters of autoclaves with electromagnetic stirring, add 108 grams of vinyl sulfite and 6.0 grams of catalyst (produced by 5.0 grams of polyethylene glycol (PEG) 200 (produced by Guangzhou Jietu Chemical Company) and 1.0 grams of potassium iodide Mixed complex), after replacing the air with nitrogen, add 100 grams of ethylene oxide. Then, heat the temperature-raising reaction mixture, and when the reaction temperature rises to 130° C., feed sulfur dioxide to 5 MPa, and react for about 2 hours while maintaining the temperature and pressure. Pass cooling water in the autoclave, cool to 50 ℃, emit the product in the still, obtain the thick product of the vinyl sulfite of 347.9 grams. The resulting crude product was purified by vacuum distillation to obtain 341.4 grams of vinyl sulfite, which was analyzed by chromatography with a purity of 99.5% and a yield of 94.6% (relative to ethylene oxide).

Embodiment 2

[0018] In a 200 ml autoclave with electromagnetic stirring, add 80 grams of vinyl sulfite and 8.0 grams of catalyst (produced by 6.4 grams of polyethylene glycol (PEG) 400 (produced by Guangzhou Jietu Chemical Company) and 1.6 grams of bromine A complex formed by mixing sodium chloride), after replacing the air with nitrogen, add 100 grams of ethylene oxide. Then, heat the temperature-raising reaction mixture, and when the reaction temperature rises to 150° C., feed sulfur dioxide to 4 MPa, and react for about 2 hours while maintaining the temperature and pressure. Pass cooling water in the autoclave, be cooled to 50 ℃, emit the product in the still, obtain the thick product of the vinyl sulfite of 332.2 grams. The obtained crude product was subjected to vacuum distillation and purification to obtain 323.5 grams of vinyl sulfite. Through chromatographic analysis, the purity was 99.2%, and the yield was 98.4% (relative to ethylene oxide).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com