Multi-component multi-layer hard thin film material for minitype drill bit surface modification and preparation method thereof

A technology of micro-drills and thin-film materials, which can be applied to metal material coating processes, coatings, and layered products. It can solve the problems of hole position accuracy, hole wall roughness, and microhardness. Wide controllable range, solve the effect of hole position accuracy and fine film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

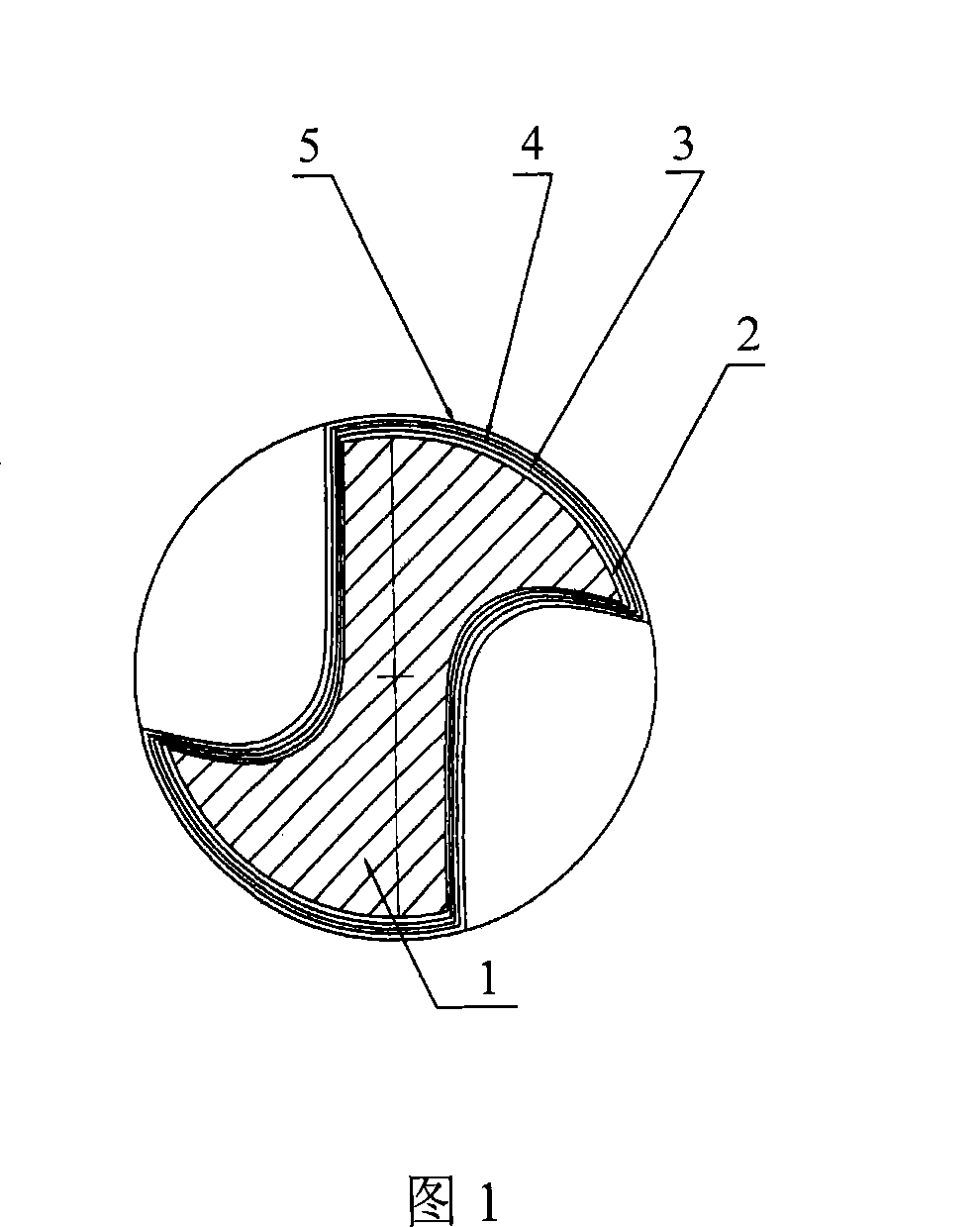

Image

Examples

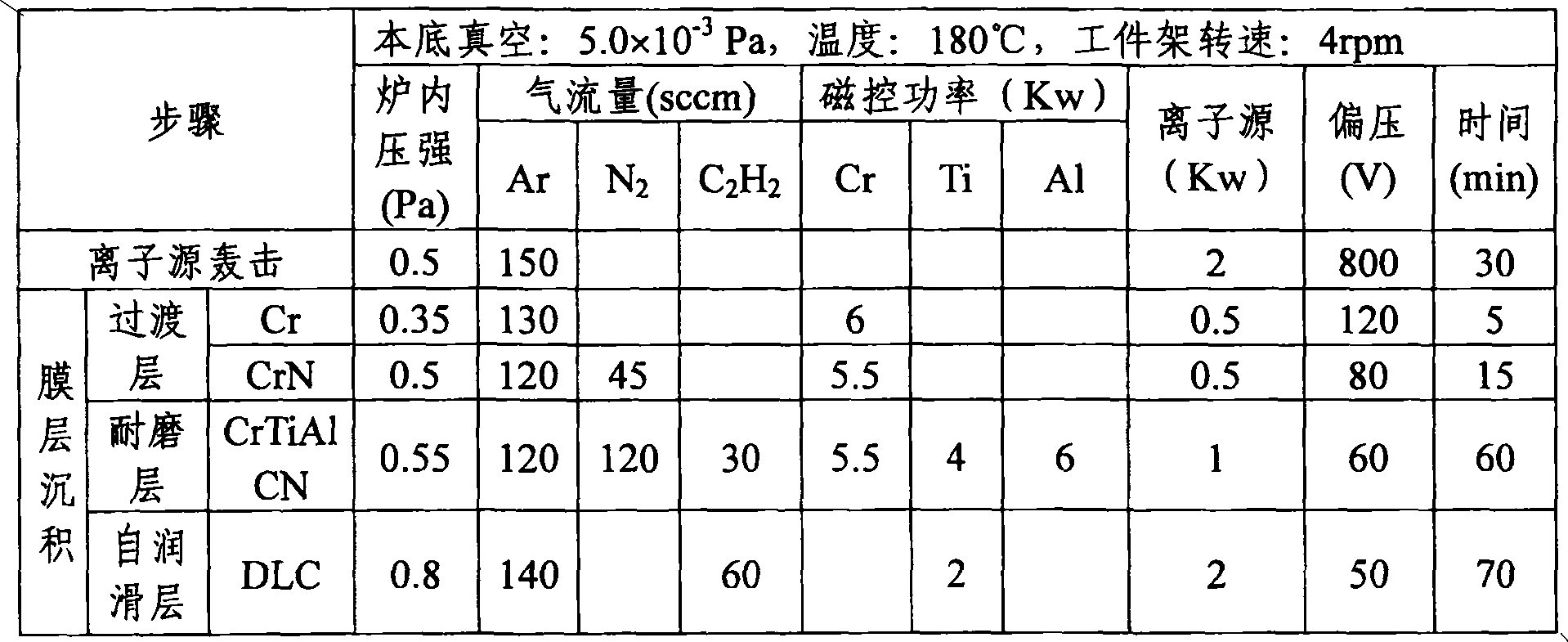

Embodiment 1

[0029] Table 1 process flow table

[0030]

[0031] Three target materials of Cr, Ti and Al are used, and the gas is high-purity Ar and N 2 and C 2 h 2 , The substrate is a Φ0.4mm micro-drill. The thickness of the multi-layer hard film Cr / CrN / CrTiAlCN / DLC deposited sequentially is 0.1, 0.25, 0.85, 0.6 μm; The coefficient of friction of the layer is 0.2. Use this coated micro-drill to drill a 6-layer PCB board with a thickness of 2.0mm, and the speed is 120,000 rpm. It reached 25500 (7000 / 6000 / 5000 / 4000 / 3500), while the average number of holes drilled by uncoated micro-drills was 10000 (3000 / 2000 / 2000 / 1500 / 1500).

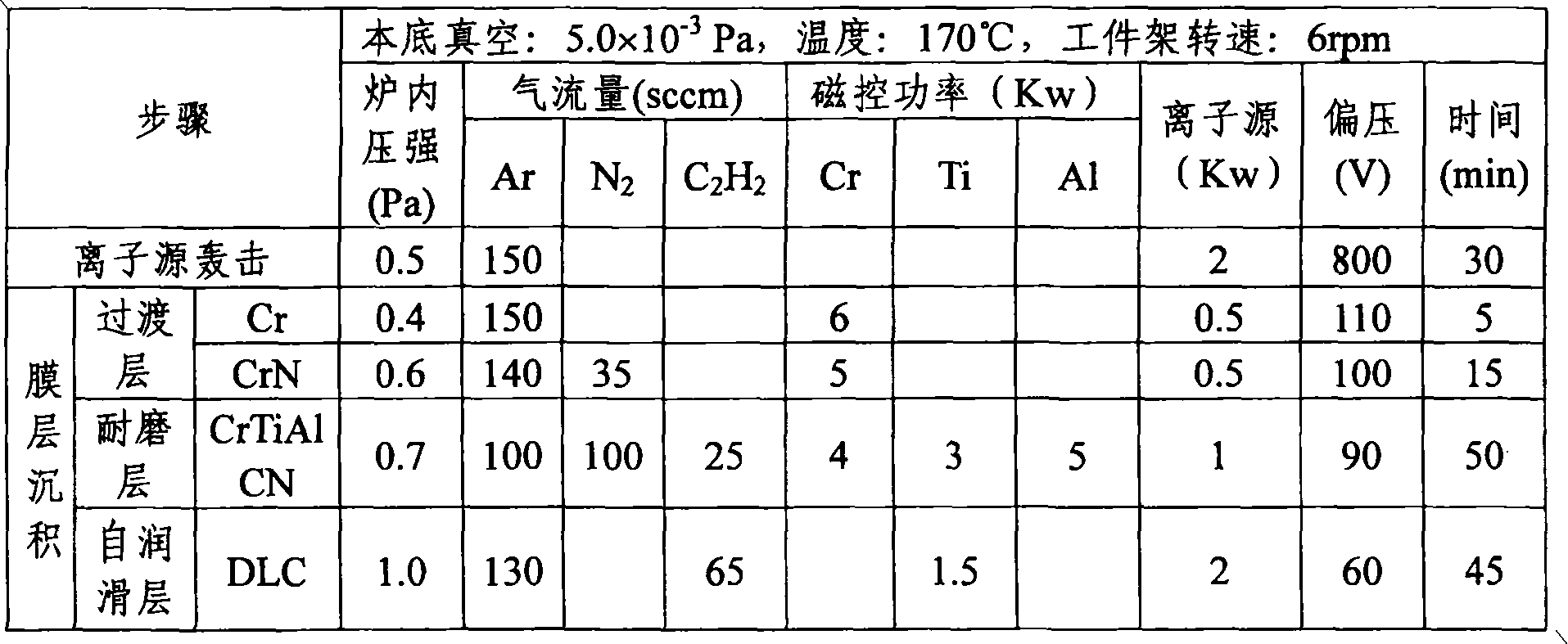

Embodiment 2

[0033] Table 2 process flow table

[0034]

[0035]Three target materials of Cr, Ti and Al are used, and the gas is high-purity Ar and N 2 and C 2 h 2 , The substrate is a φ0.25mm micro-drill. The thickness of multi-layer hard film Cr / CrN / CrTiAlCN / DLC deposited sequentially is 0.1, 0.2, 0.6, 0.4 μm respectively; The coefficient of friction of the layer is 0.25. Use this coated micro-drill to drill an 8-layer PCB board with a thickness of 1.6mm, and the speed is 140,000 rpm. According to the use process of the micro-drill, and under the condition of meeting the processing quality standards of the PCB board, each coated micro-drill drills holes The average number reached 14500 (5000 / 4000 / 3000 / 2500 / 0), while the average number of holes drilled by the uncoated micro-drill was 6000 (2000 / 1500 / 1500 / 1000 / 0).

Embodiment 3

[0037] Table 3 process flow table

[0038]

[0039] Three target materials of Cr, Ti and Al are used, and the gas is high-purity Ar and N 2 and CH 4 , The substrate is a welded carbide micro-drill of Φ0.3mm. The thickness of multi-layer hard film Cr / CrN / CrTiAlCN / DLC deposited sequentially is 0.1, 0.2, 1.0, 0.5 μm; The coefficient of friction of the layer is 0.15. Use this coated micro-drill to drill 2 layers of a 4-layer PCB board stack with a thickness of 0.7mm at a speed of 135,000 rpm. The average number of holes drilled by the micro-drills reached 23500 (6000 / 5000 / 5000 / 4000 / 3500), while the average number of holes drilled by the uncoated micro-drills was 9000 (2500 / 2000 / 2000 / 1500 / 1000).

[0040] The microhardness of the multi-layer hard film material prepared according to the micro-drill surface modification provided by the present invention and its preparation method reaches HV2500-3500, the film / base bonding force is ≥ 70N, and the friction coefficient is 0.1 ~0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com