Method for preparing methylphenyl hydrogen-containing silicone oil

A technology of methyl phenyl and polymethyl hydrogen cyclosiloxane is applied in the field of preparation of hydrogen-containing silicone oil to achieve the effects of convenient industrialization, simple operation and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

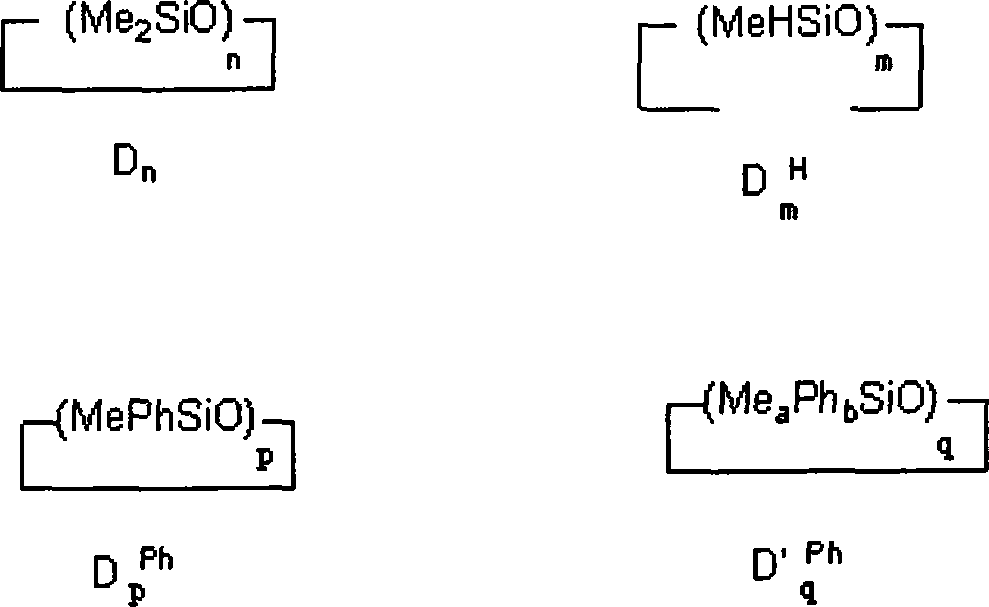

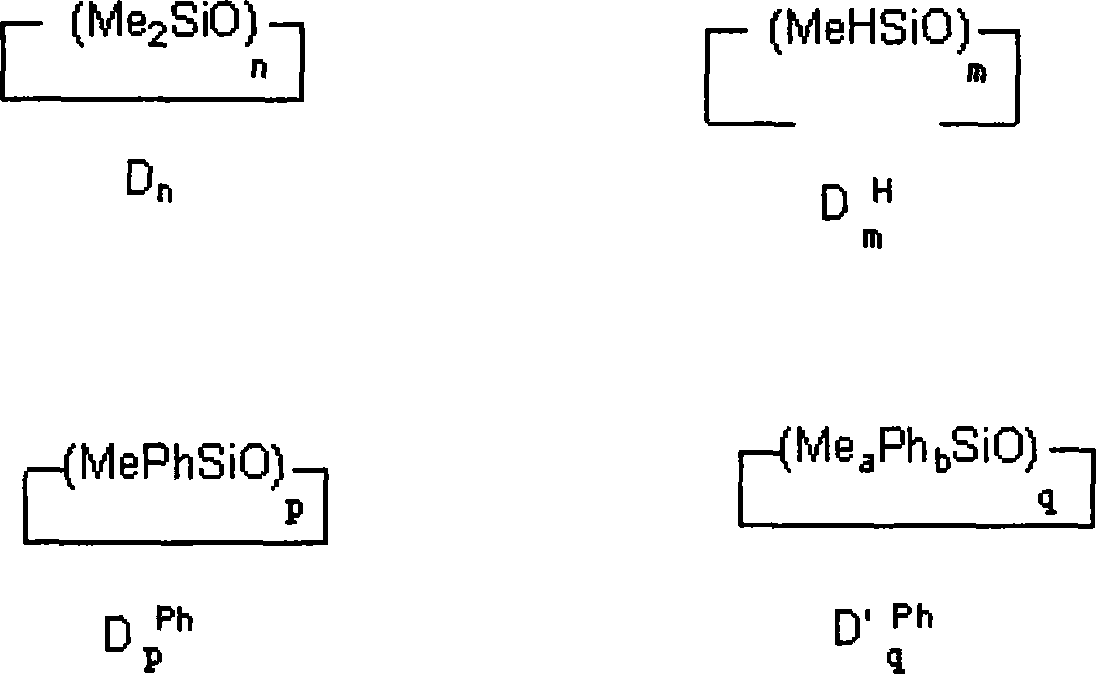

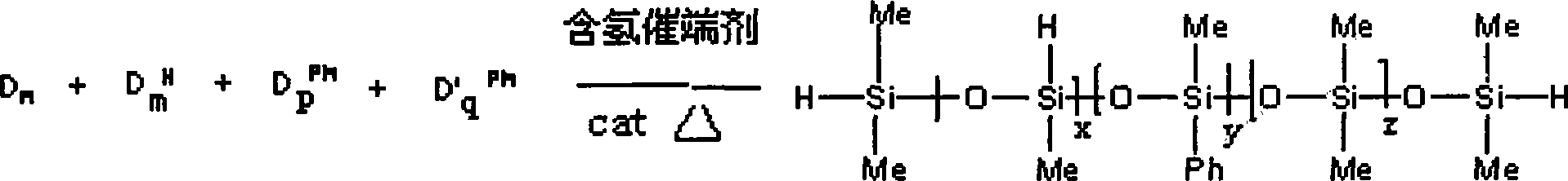

Method used

Image

Examples

Embodiment 1

[0031] in N 2 Add 63.8g of polymerized monomer to a 500mL dry three-neck flask under protection p Ph and 36.2gD 4 H , at 35℃~45℃ / -0.096MPa to remove the water in the polymerized monomer, and then add 2.6g of end-capping agent 1,1,3,3-tetramethyl-1,3-dihydrodisiloxane alkanes, 5.0 g catalyst (large pore size strongly acidic cation exchange resin), 100 mL toluene solvent, polymerize at 65° C. for 5 h, and recover the large pore size strong acid cation exchange resin by suction filtration. Atmospheric pressure through N 2 Evaporate most of the toluene under protection, then reduce the pressure to -0.096MPa, gradually raise the temperature to 205°C to remove the remaining solvent and low molecular weight compounds, cool to room temperature, add 1wt% powdered activated carbon of the total mass of the mixture and stir, then pump The powdered activated carbon was recovered by filtration, and the filtrate was colorless and transparent methylphenyl hydrogen-containing silicone oil...

Embodiment 2

[0033] Using the same method as in Example 1, with 37.1gD p Ph , 27.7gD 4 H , 35.2g D' q Ph 1.8g of 1,1,3,3-tetramethyl-1,3-dihydrodisiloxane as end-capping agent, 5.0g of large-pore strongly acidic cation exchange resin as catalyst, and 100mL of toluene as solvent , after the polymerization and post-treatment are completed, the refractive index n of the obtained methylphenyl hydrogen-containing silicone oil D 25 =1.4720, the rotational viscosity at 25°C is about 150mpa·s. through 1 H-NMR records Si-H mass percentage content 0.4%, Ph / Si (molar ratio) is 0.33, and GPC records number average molecular weight (Mn) and is 2.7 * 10 3 g.mol -1 , MWD is 1.69.

Embodiment 3

[0035] Adopt the method identical with embodiment 1, with 42.5gD p Ph , 15.1gD 4 H , 42.5g D' q Ph 2.5g of 1,1,3,3-tetramethyl-1,3-dihydrodisiloxane as the end-capping agent, 5.0g of large-pore strong acid cation exchange resin as the catalyst, and 100mL of toluene as the solvent , after the polymerization and post-treatment are completed, the refractive index n of the obtained methylphenyl hydrogen-containing silicone oil D 25 =1.4898, the rotational viscosity at 25°C is about 120mpa·s, after 1 H-NMR records Si-H mass percentage content 0.24%, Ph / Si (molar ratio) is 0.43, and GPC records number average molecular weight (Mn) and is 2.4 * 10 3 g.mol -1 , MWD is 2.27.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotational viscosity | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com