Nano composite painting canvas paint

A nano-composite and coating technology, which is applied in the direction of art coatings and coatings, can solve the problems of poor coating adhesion, coating cracks, and inability to rebound, achieving strong attraction, increasing elongation, and improving The effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

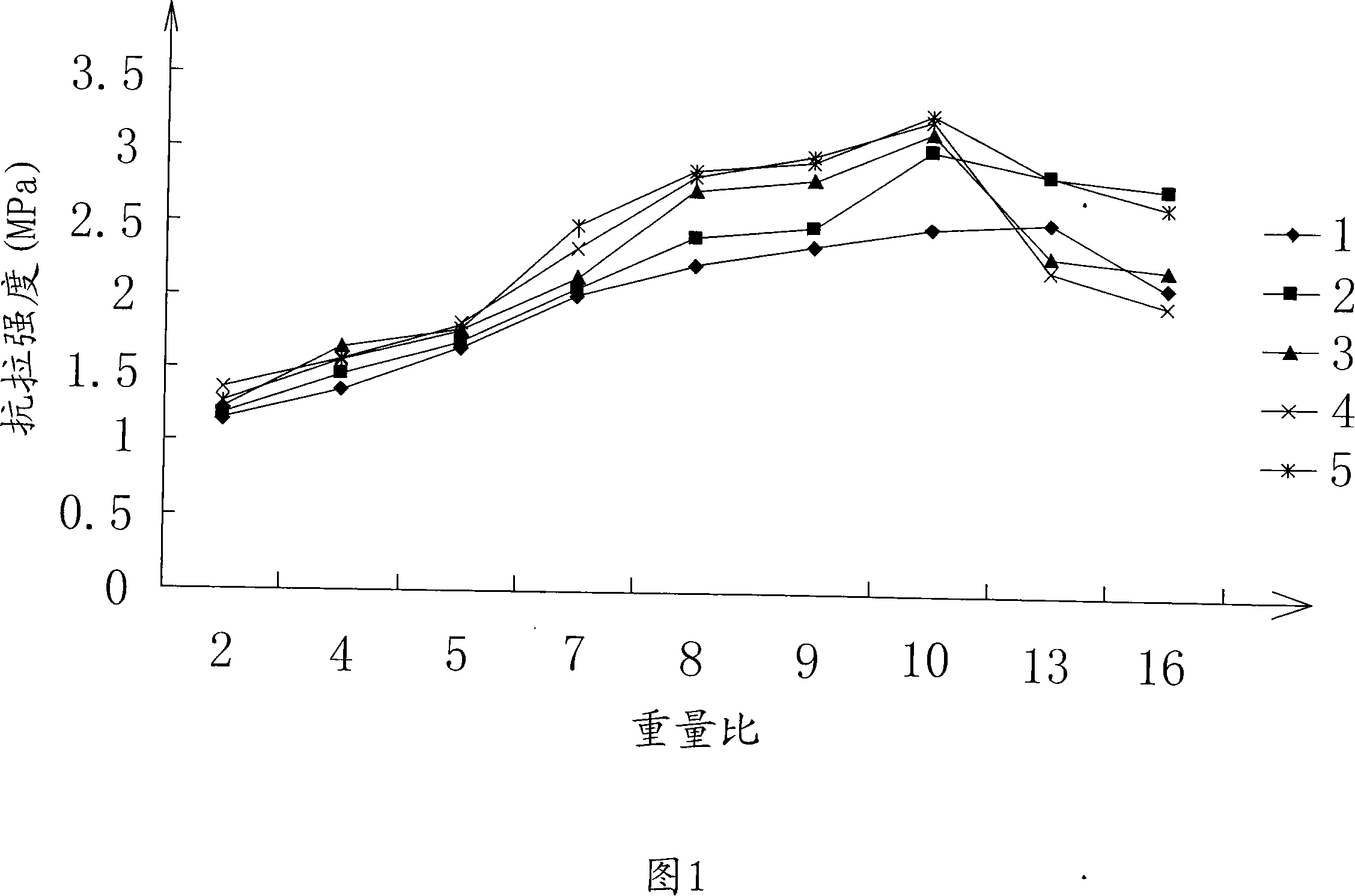

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0031] The basic preparation method is as follows: use an electric heating reaction pot to stir the mixed solvent of polyethanol resin, white filler, dispersant, anti-mold and fungicide, and diluent water according to the formula. After stirring for 10 hours, use a mixer to disperse the carbonic acid at high speed according to the formula. Calcium nano-slurries are dispersed and stirred at a speed of 500 rpm in a mixed solvent for 1 hour, and then the film-forming polymer resin solution and the remaining other coating additives are added to continue at a speed of 300 rpm. Stir until the particles are uniformly dispersed in the system to obtain the nanocomposite canvas paint of the present invention. Among them, the mixer can choose the SJ1200 mixer produced by Jiangyin Fine Chemical Machinery Co., Ltd., the weight percentage of nano calcium ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com