A deep ditch groove high-power MOS device and the corresponding manufacturing method

A MOS device, high-power technology, applied in the field of deep trench high-power MOS devices and its manufacturing, can solve the problems of device capacitance increase, limitation, device switching speed reduction, etc., to achieve the effect of increasing breakdown voltage and diluting power lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

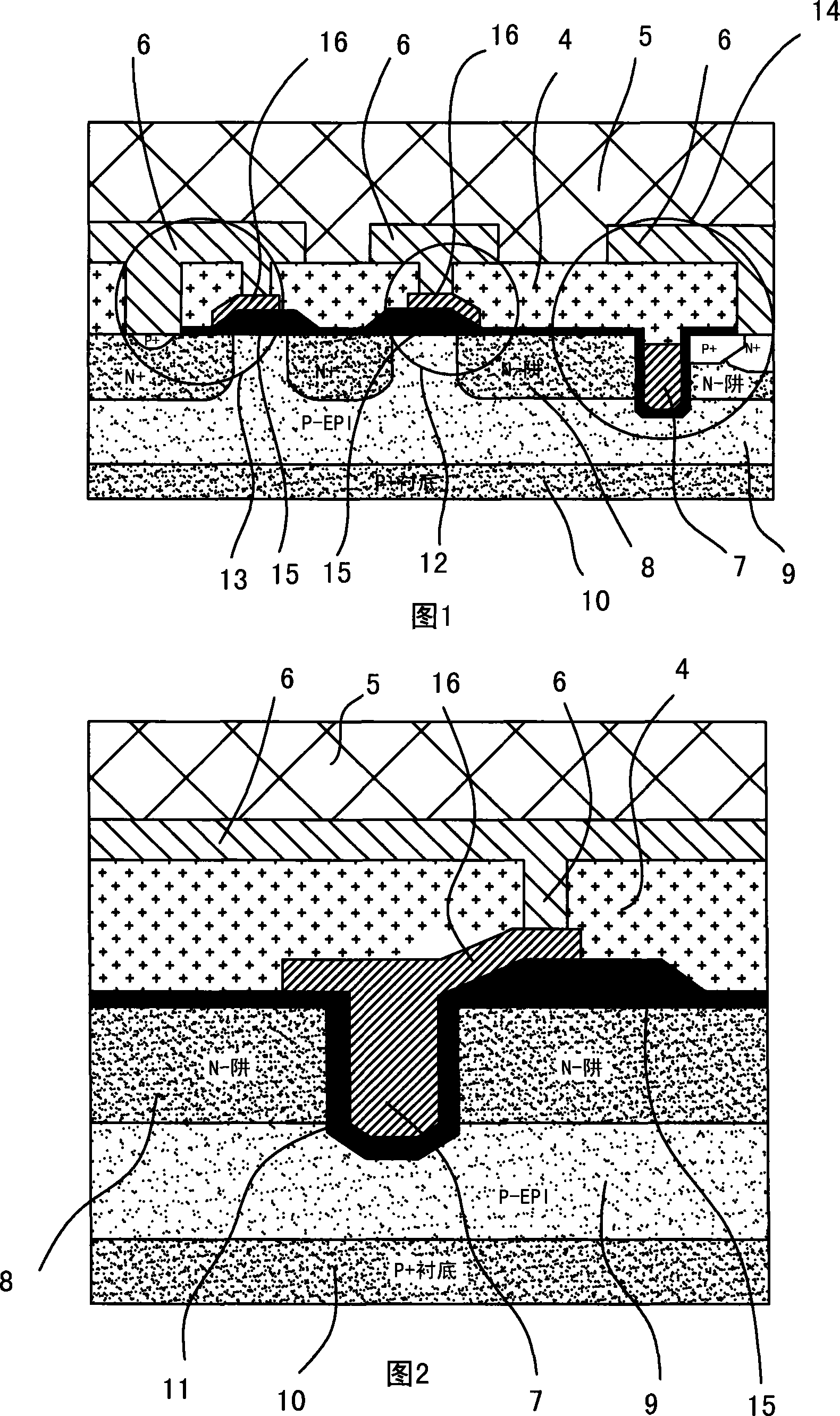

[0054] Embodiment: A deep trench high power P-type MOS device

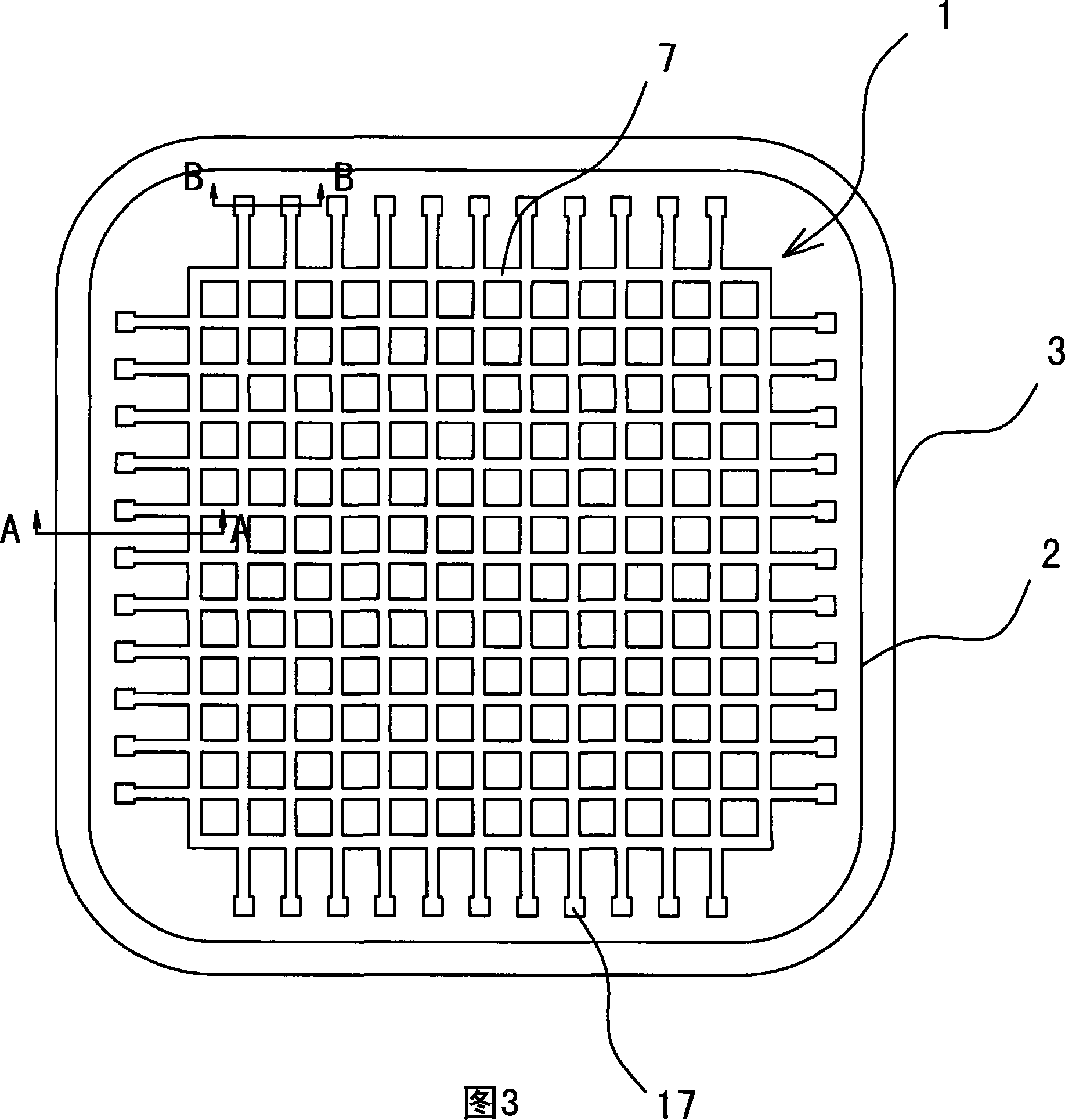

[0055] 3 is a schematic plan view of a deep trench high-power P-type MOS device in a top view state. It can be seen from the figure that a unit cell array 1 is provided in the central area of the MOS device, and a terminal protection structure is provided on the periphery of the unit cell array 1 . The unit cell array 1 is made of trench-type conductive polysilicon 7 to connect each unit cell in parallel to form a whole. The terminal protection structure is composed of a protection ring 2 located in the inner ring and a cut-off ring 3 located in the outer ring. In this embodiment, there is only one guard ring, but two or more guard ring structures may also be used, which is determined by actual needs.

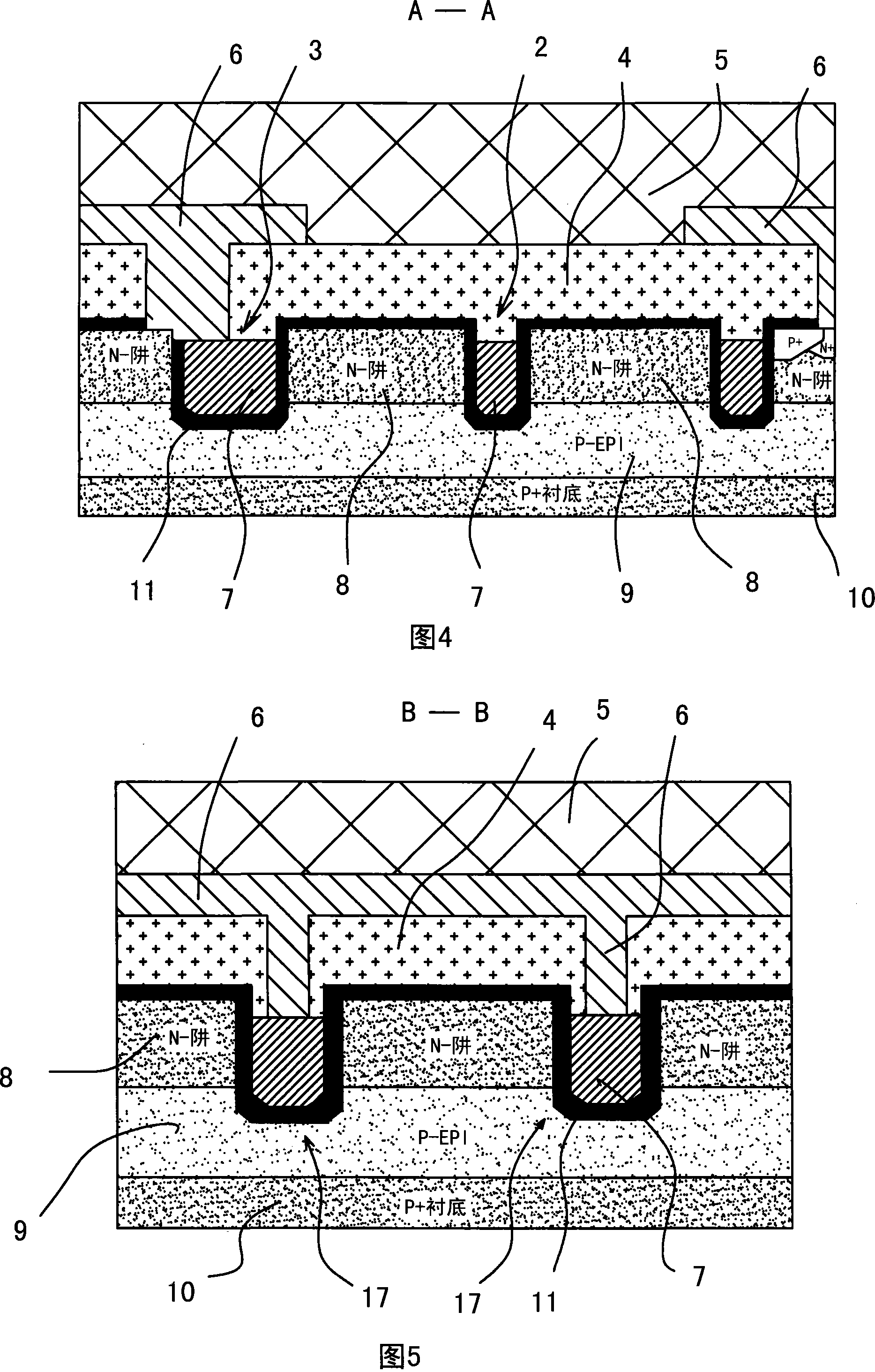

[0056] FIG. 4 is a cross-sectional view of A-A of FIG. 3 , which is a schematic cross-sectional view of a deep trench high-power MOS device according to an embodiment of the present invention. It can be seen f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com