Process for producing white carbon black/solution polymerized butadiene styrene rubber nano-composite material

A technology of solution-polymerized styrene-butadiene rubber and nano-composite material is applied in the field of preparation of white carbon black and solution-polymerized styrene-butadiene rubber nano-composite material, and can solve problems such as inability to compound, and achieves simple and fast method, simple and convenient process, and convenient preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

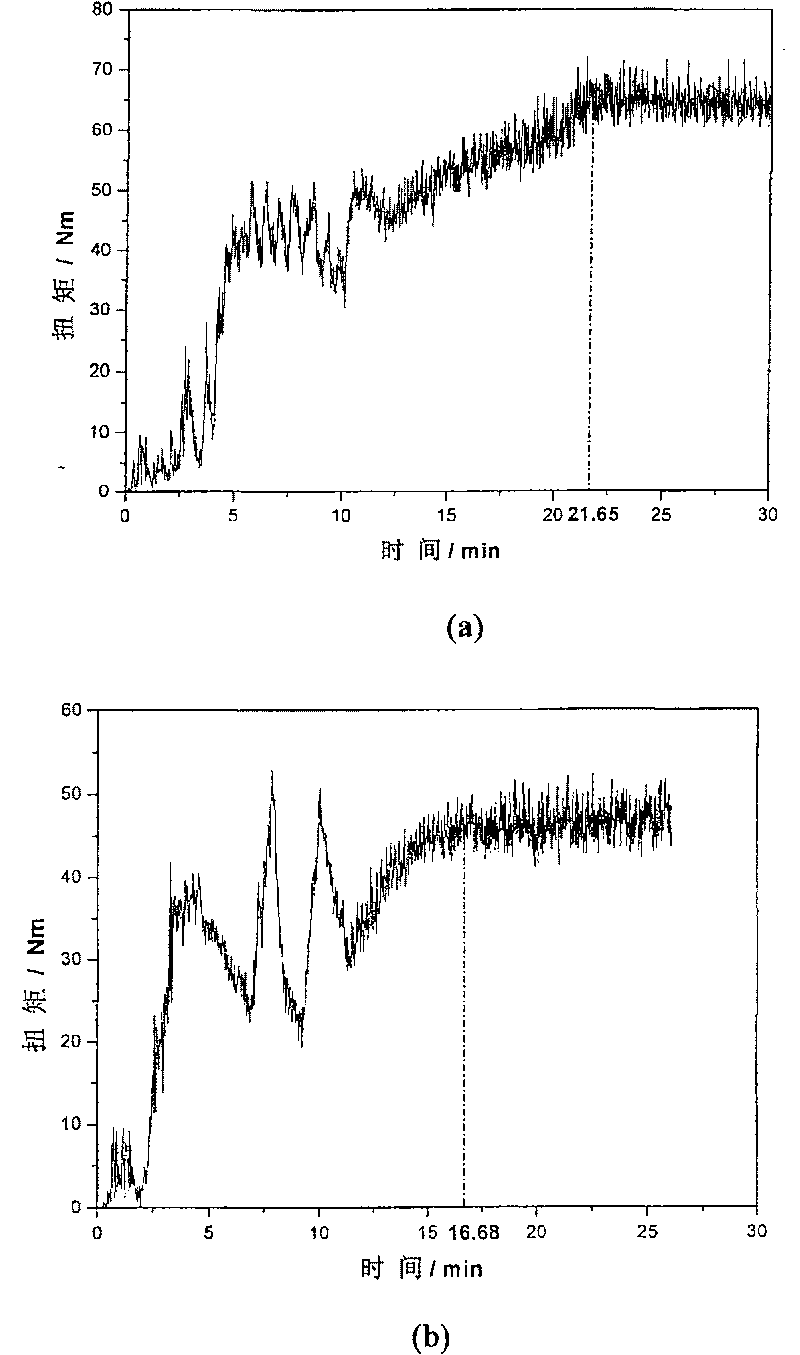

Embodiment 1

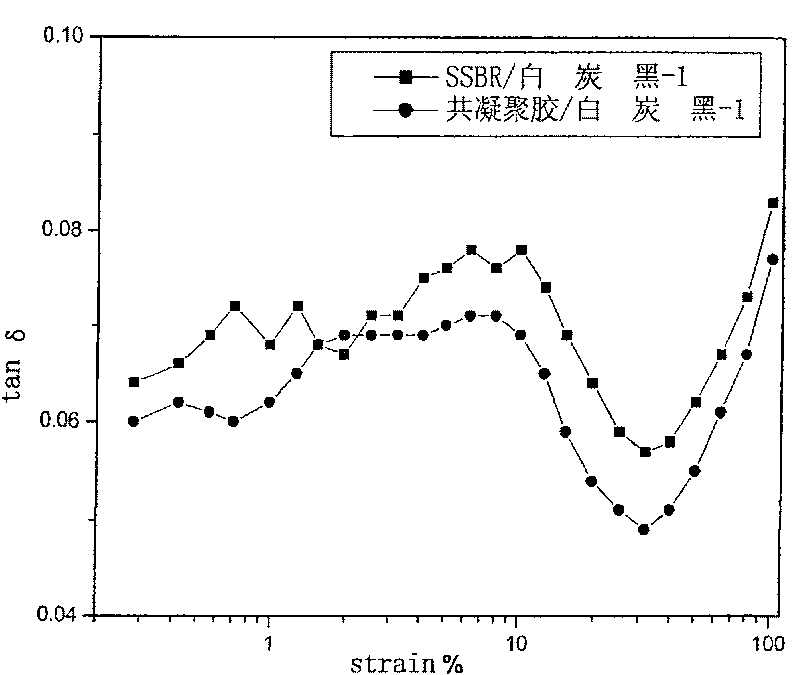

[0033] 20g of nano-silica powder (TIXOSIL 383 type, purchased from France Rhodia Company) was added to the ethanol solution of 80g / L N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane , where N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane accounts for 5wt% of the white carbon black, stir at room temperature for 12h, after mixing evenly, let the solvent evaporate, and then at 80°C React for 4h to obtain organic nano-silica powder; weigh 3g of this organic nano-silica powder and cyclohexane solvent to mix it into a 20g / L solution, stir evenly, and add to a solid content of 0.1g / L ml, a volume of 1000ml of solution-polymerized styrene-butadiene rubber, stirred at a water bath temperature of 30°C for 36h, dried after desolventization to obtain the white carbon black / solution-polymerized styrene-butadiene rubber nanocomposite material containing 3wt% white carbon black (total Gel-1). Table 1 shows the comparison of the parameters of co-coagulation gel-1 and SSBR-1 in this example.

...

Embodiment 2

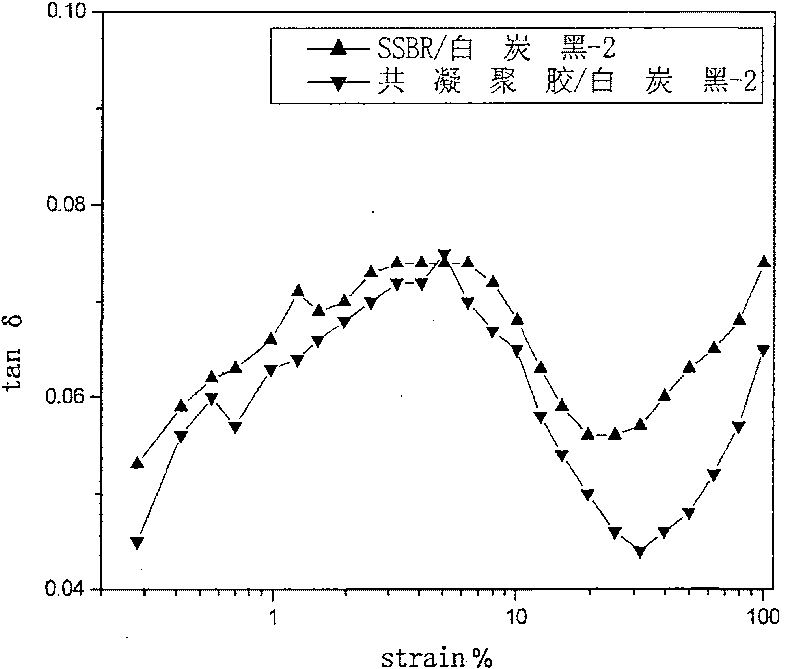

[0040] 20g of nanometer white carbon black powder (TIXOSIL 383 type, purchased from France Rodi Industry Company) was added to the ethanol solution of 100g / L N-(β-aminoethyl)-γ-aminopropyltriethoxysilane Among them, N-(β-aminoethyl)-γ-aminopropyltriethoxysilane accounted for 10wt% of the white carbon black, stirred at room temperature for 18h, after mixing evenly, left to stand to evaporate the solvent, and then at 90 ℃ for 1 hour to obtain organic nano-silica powder; weigh 3g of the organic nano-silica powder and cyclohexane solvent to prepare a 60g / L solution, stir evenly, and add to a solid content of 0.05 g / ml and a volume of 2000ml solution-polymerized styrene-butadiene rubber solution, stirred at a water bath temperature of 40°C for 24 hours, dried after removing the solvent to obtain a silica / solution-polymerized styrene-butadiene rubber nanocomposite material containing 3wt% white carbon black (co-coagulation gel-2). Table 3 shows the comparison of the parameters of c...

Embodiment 3

[0048] 20g of nano-silica powder (TIXOSIL 383 type, purchased from France Rhodia Company) was added to the ethanol solution of 1g / L N-(β-aminoethyl)-γ-aminopropyltriethoxysilane Among them, N-(β-aminoethyl)-γ-aminopropyltriethoxysilane accounted for 7wt% of the white carbon black, stirred at room temperature for 6h, after mixing uniformly, left to stand to evaporate the solvent, and then at 80 React at ℃ for 3 hours to obtain organic nano-silica powder; weigh 7g of the organic nano-silica powder and cyclohexane solvent to form a 100g / L solution, stir evenly, and add to the solid content of 0.08 g / ml and a volume of 1250ml solution-polymerized styrene-butadiene rubber solution, stirred at a water bath temperature of 50°C for 6 hours, and dried after removing the solvent to obtain a silica / solution-polymerized styrene-butadiene rubber nanocomposite material containing 7wt% white carbon black (co-coagulated gel-3). Table 5 shows the comparison of the parameters of co-coagulation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com