Device and method for production synthesis gas energy conservation and emission reduction of static bed gas making furnace

A technology of energy saving and emission reduction, gas making furnace, applied in fixed bed gasification, manufacturing combustible gas, petroleum industry and other directions, can solve the problems of high, residual carbon, polluting the environment, low steam decomposition rate and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

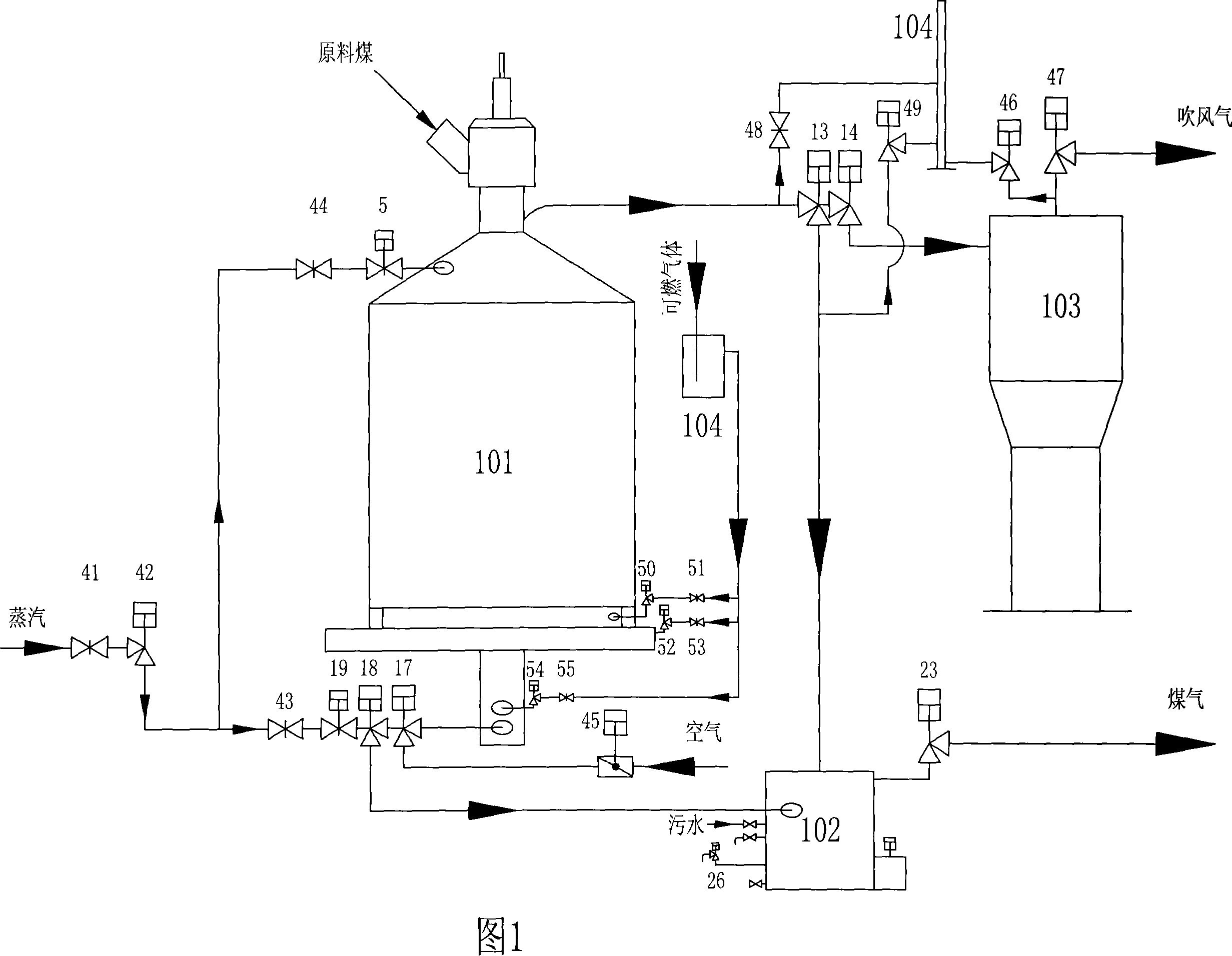

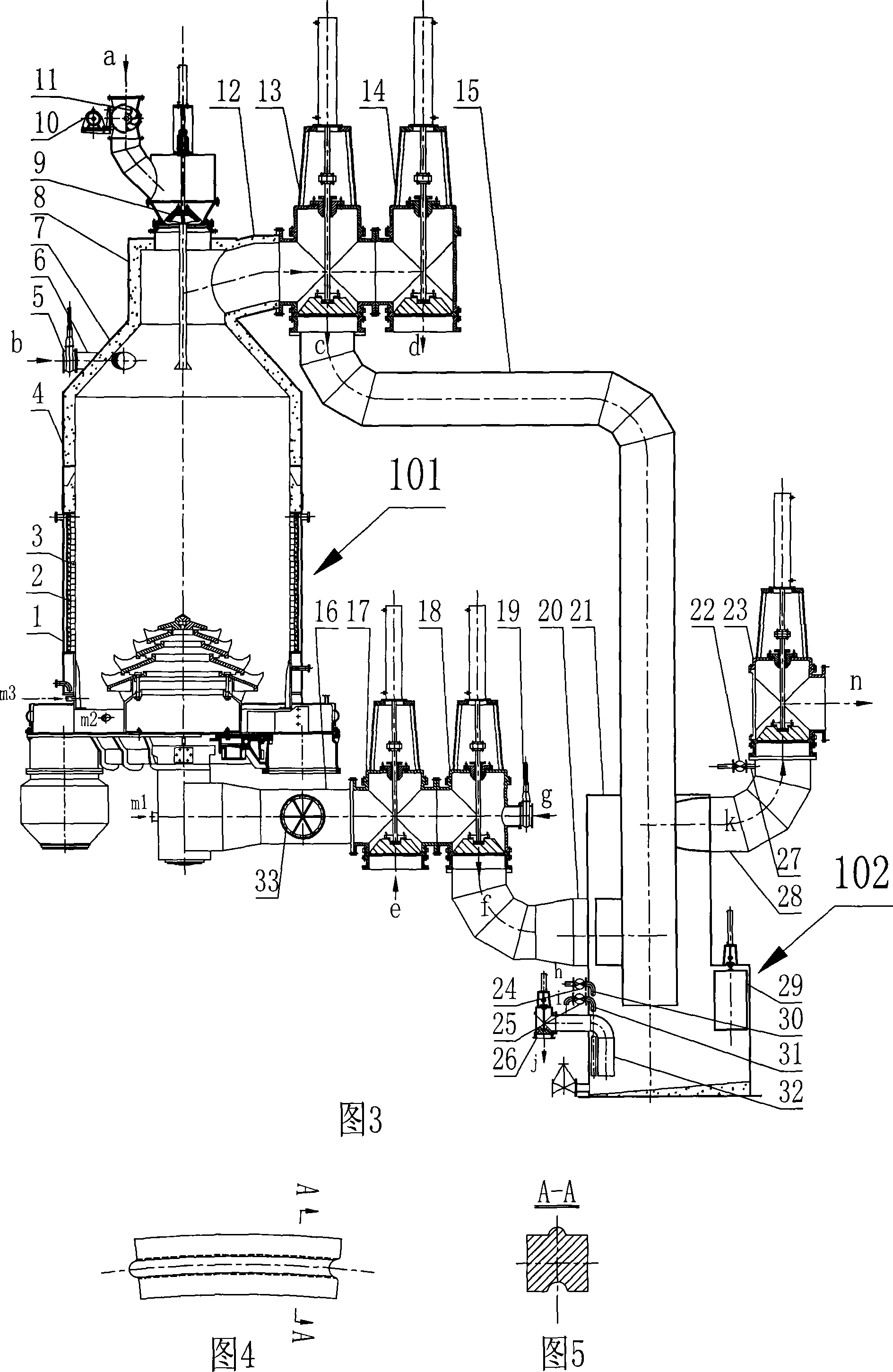

Method used

Image

Examples

Embodiment 1

[0069] In the hot wall high-efficiency gas-making furnace system, Shanxi anthracite (calorific value 28164kJ / kg) is used as raw material, 80% potassium carbonate, 17% sodium acetate, and 3% manganese dioxide are used as catalysts by weight, and the weight of raw coal is 0.6 % Proportion Use the gasification catalyst, add water to the catalyst to form a 30% aqueous solution and spray it on the raw coal into the furnace, and send in the composition containing CH in the upper blowing gas stage 4 36%, H 2 25%, N 2 39% synthetic ammonia releases air at 300Nm3 / h, and the gasification layer temperature is 1000-1250°C.

[0070] After operation analysis and comparison, CH in semi-water gas 4 0.8%, the residual carbon in the slag of the gas-making furnace is reduced to below 7%, and the coal consumption per ton of ammonia is reduced by 162kg.

Embodiment 2

[0072] In the hot wall high-efficiency gas-making furnace system, Shanxi anthracite (calorific value 28164kJ / kg) is used as raw material, 65% of sodium carbonate, 30% of potassium acetate, and 5% of manganese dioxide are used as catalysts by weight, and 0.5% of the weight of raw coal is used. % Proportion Use gasification catalyst, add water to the catalyst to make 40% aqueous solution and spray it on the raw coal into the furnace, and send in components containing CO16%, H 2 20%, CH 4 13%, CH 3 OH1%, CO 2 10%, N 2 40% methanol release air 400Nm3 / h. After operation comparison, the residual carbon in the slag of the gas-making furnace is reduced to less than 6%, and the coal consumption per ton of alcohol is reduced by 196kg.

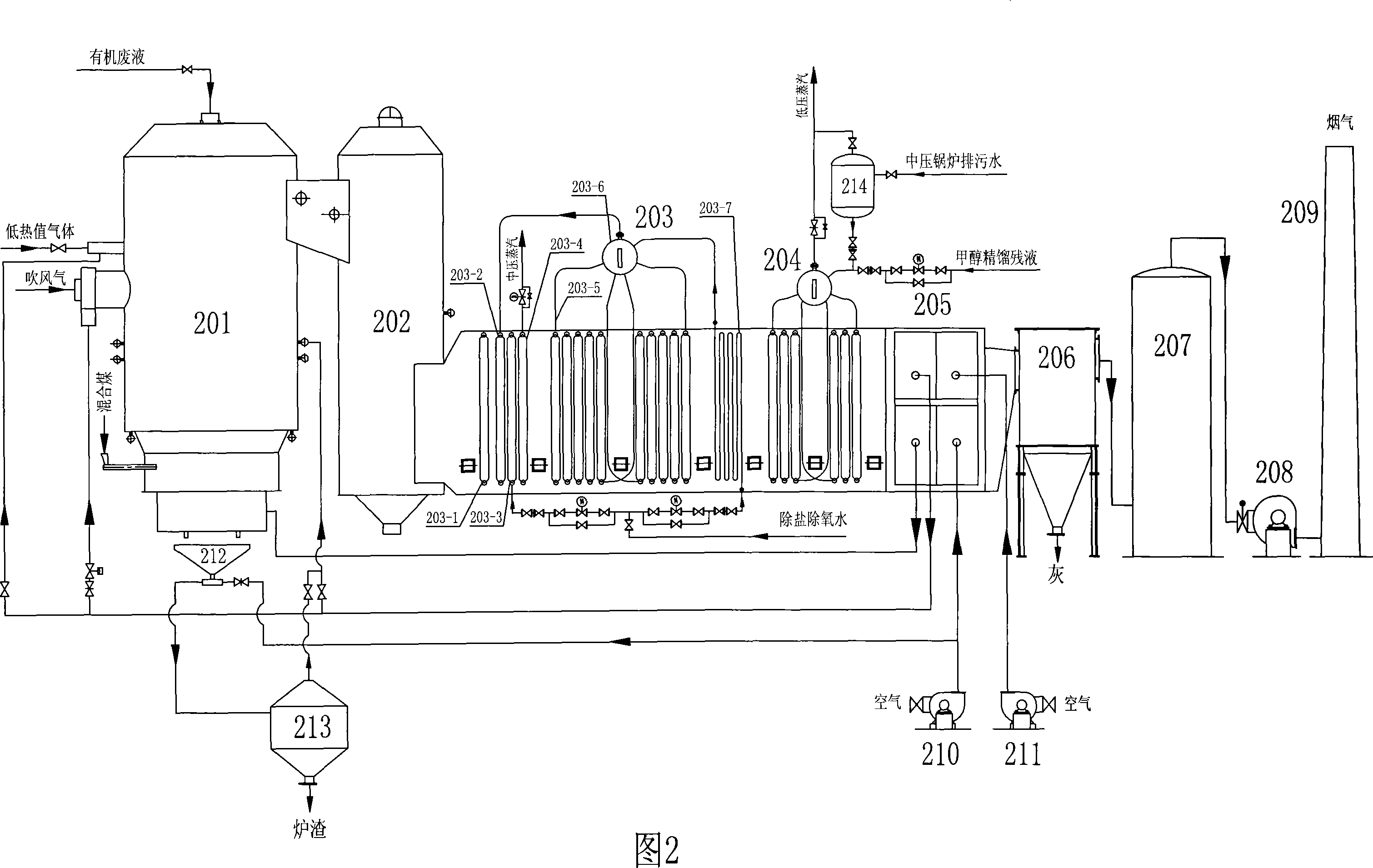

[0073] On the basis of the above improvements, in order to further save energy and reduce emissions, the following steps are also included, specifically:

[0074] A) co-combustion of sewage pond coal slime, blowing air, coal ash, and gas-making slag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com