Composite porous membrane, method for production thereof, solid polymer electrolyte membrane, and fuel cell

A technology of polymer film and porous film, which is applied in the field of functional film, can solve the problems of easy short circuit, pinhole, cross leakage and other problems of electrodes, and achieve the effect of improving current-voltage characteristics, enhancing strength and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

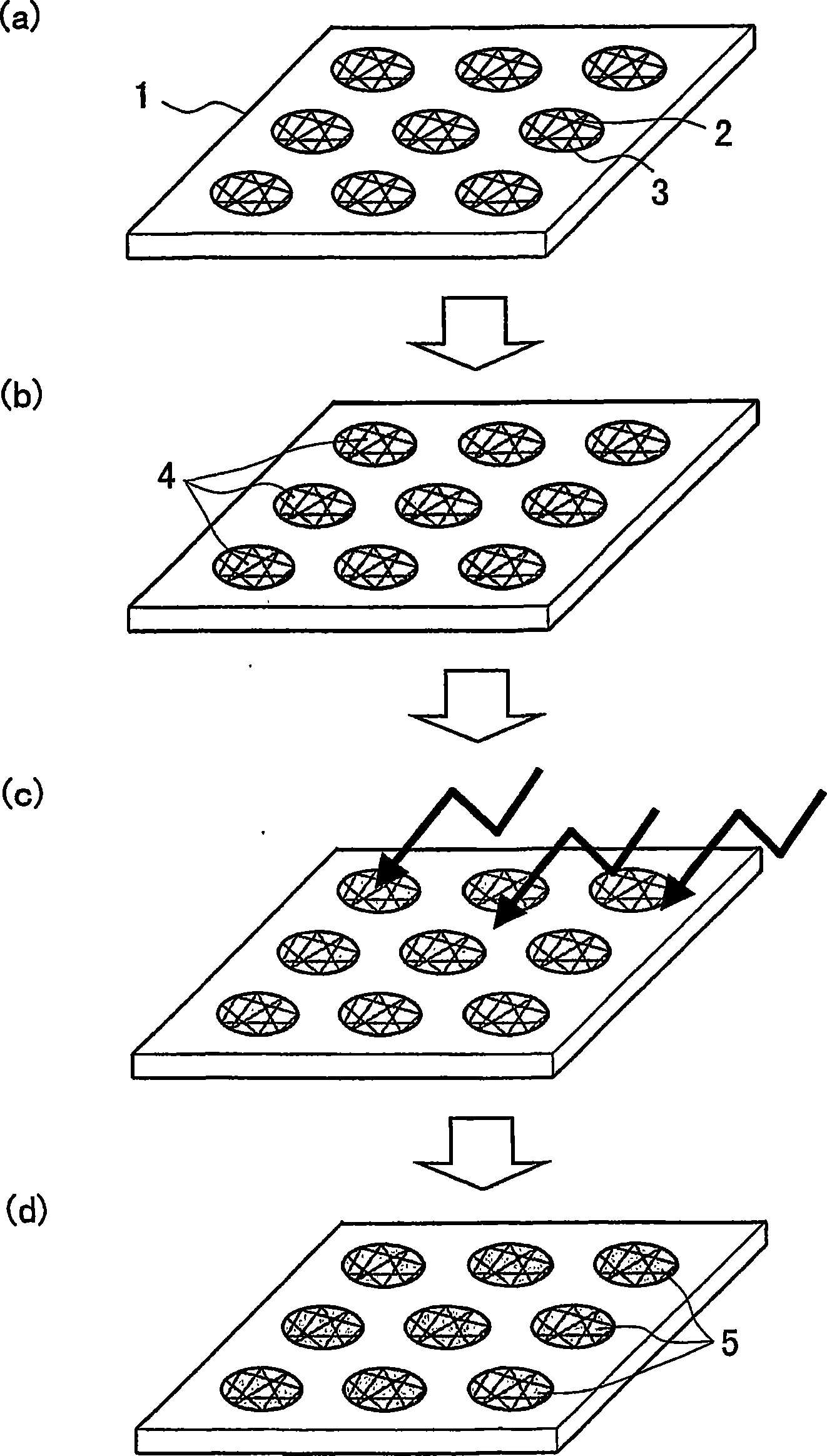

[0071] A highly functional composite electrolyte membrane for a fuel cell including a porous support was fabricated by performing membrane processing using an ultrashort pulse laser according to the procedure shown in FIG. 1 . In a specific manufacturing method, a polymer membrane containing a fibrous material (preferably non-conductive) whose fiber length is larger than the pore size to be processed is irradiated with an ultrashort pulse laser to form a porous membrane with a structure as shown in FIG. 1 .

[0072] The fiber material used preferably has 10 -5 to 10 -2 Volume resistivity in Ω / cm. But by mixing with membrane material, insulation can be improved. Therefore, usable materials are not limited to this material. The fiber material preferably has a fiber length of 1 μm to 10 μm and an aspect ratio (average length÷average diameter) of 10 or more in consideration of film processing and maintaining conductivity.

[0073] The polyetheretherketone (PEEK) film mixed wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com