Biologic absorbent for adsorbing heavy metal and preparing method thereof

A biological adsorbent, a technology for heavy metal adsorption, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of perishable adsorption operation and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

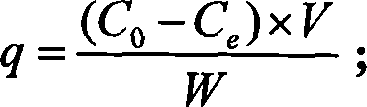

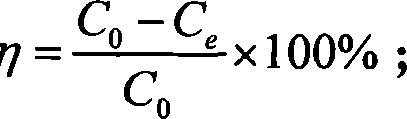

[0054] Example 1: Ni under experimental conditions 2+ Adsorption

[0055] The first step: processing of kelp powder

[0056] Freeze-dry the fresh kelp for 24 hours, crush it into dry kelp powder with a particle size of 90% of 30 μm by airflow, and set aside; the freeze-drying temperature is -56°C, and the vacuum degree is 15Pa; the freeze-drying equipment is selected from Beijing Detianyou Technology Development Co., Ltd. Company, FD-1 PF Freeze Dryer.

[0057] The second step: embedding treatment solution

[0058] Calcium chloride is dissolved in deionized water, and the embedding treatment solution is prepared by stirring evenly;

[0059] The consumption of described calcium chloride is to add 4.25g in every 100ml deionized water;

[0060] The third step: making sodium alginate and gelatin glue

[0061] put sodium alginate and gelatin into deionized water, and stir evenly at a temperature of 60°C to prepare sodium alginate and gelatin glue;

[0062] The consumption of...

Embodiment 2

[0075] The first step: processing of kelp powder

[0076] Freeze-dry the fresh kelp for 72 hours, crush it into dry kelp powder with a particle size of 0.3-30 μm by airflow, and set aside for use; the freeze-drying temperature is -40°C, and the vacuum degree is 20Pa;

[0077] The second step: embedding treatment solution

[0078] Calcium chloride is dissolved in deionized water, and the embedding treatment solution is prepared by stirring evenly;

[0079] The consumption of described calcium chloride is to add 4g in every 100ml deionized water;

[0080] The third step: making sodium alginate and gelatin glue

[0081] put sodium alginate and gelatin into deionized water, and stir evenly at a temperature of 75°C to prepare sodium alginate and gelatin glue;

[0082] The consumption of described sodium alginate is to add 4g in every 100ml acetic acid;

[0083] The consumption of described gelatin is to add 2g in every 100ml deionized water;

[0084] Step Four: Embedding Body ...

Embodiment 3

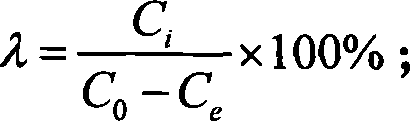

[0090] Get the biosorbent sphere prepared by 0.25g embodiment 1, and 100ml concentration is 100mg / L containing Co 2+ , Zn 2+ 、Cd 2+ 、Cu 2+ and Pb 2+ The metal solution was added to an Erlenmeyer flask, adjusted to pH = 7 ± 0.5, oscillating and adsorbing at 25°C for 5 hours to reach adsorption equilibrium, and the Co in the solution after adsorption was measured by inductively coupled plasma emission spectrometry. 2+ , Zn 2+ 、Cd 2+ 、Cu 2+ and Pb 2+ The concentration of ions, the adsorption characteristics of the adsorbent to each metal ion are as follows:

[0091] metals in solution

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com