Multiple-loop absolute type rotary encoder based on rotating transformer

A rotary encoder and resolver technology, applied in the direction of converting sensor output, instruments, measuring devices, etc., can solve the problems of limiting the application range of photoelectric encoders, difficult to overcome slip, no-speed voltage output, etc., to reduce the types of power supply and Power consumption, improved reliability, enhanced moisture and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

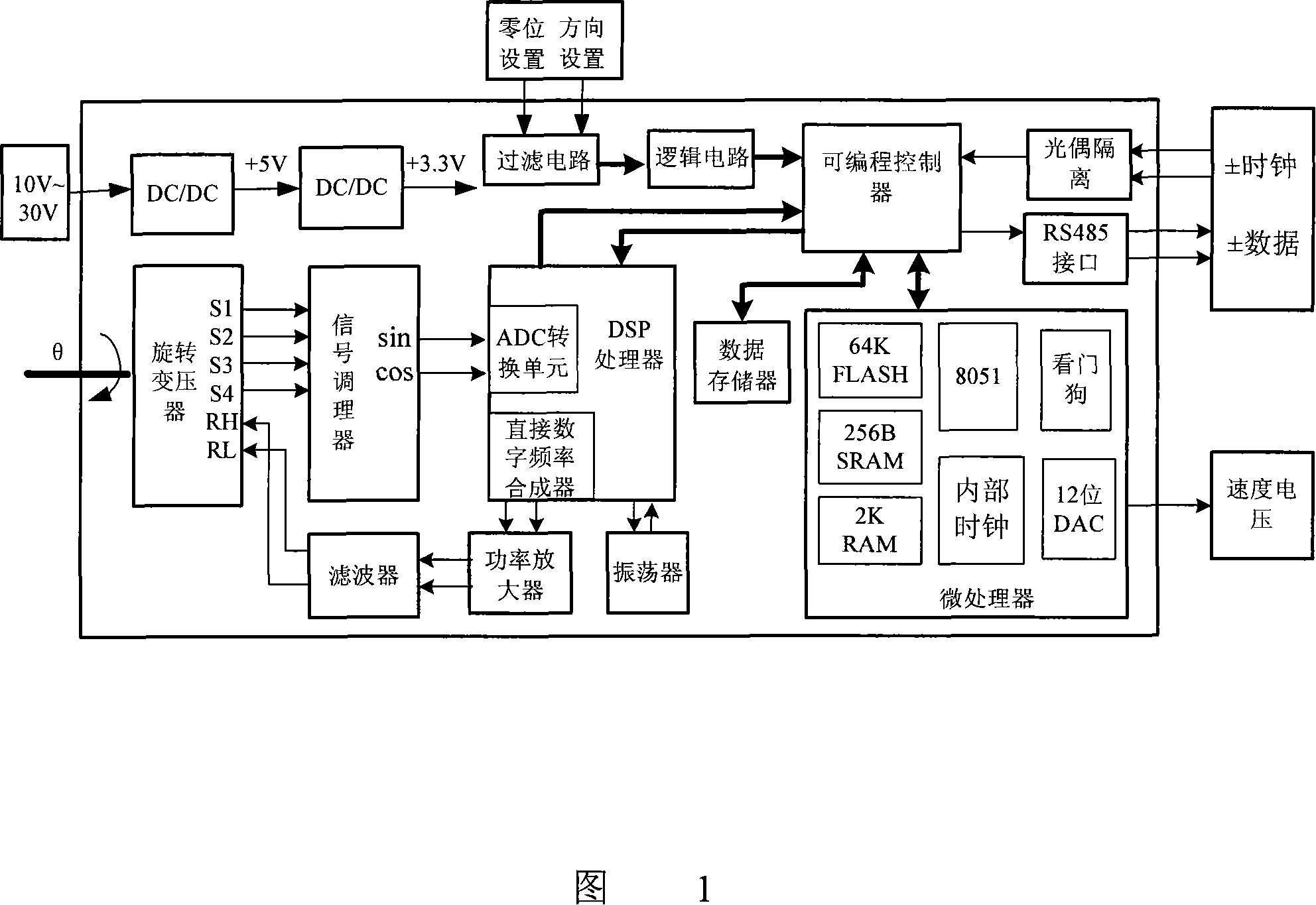

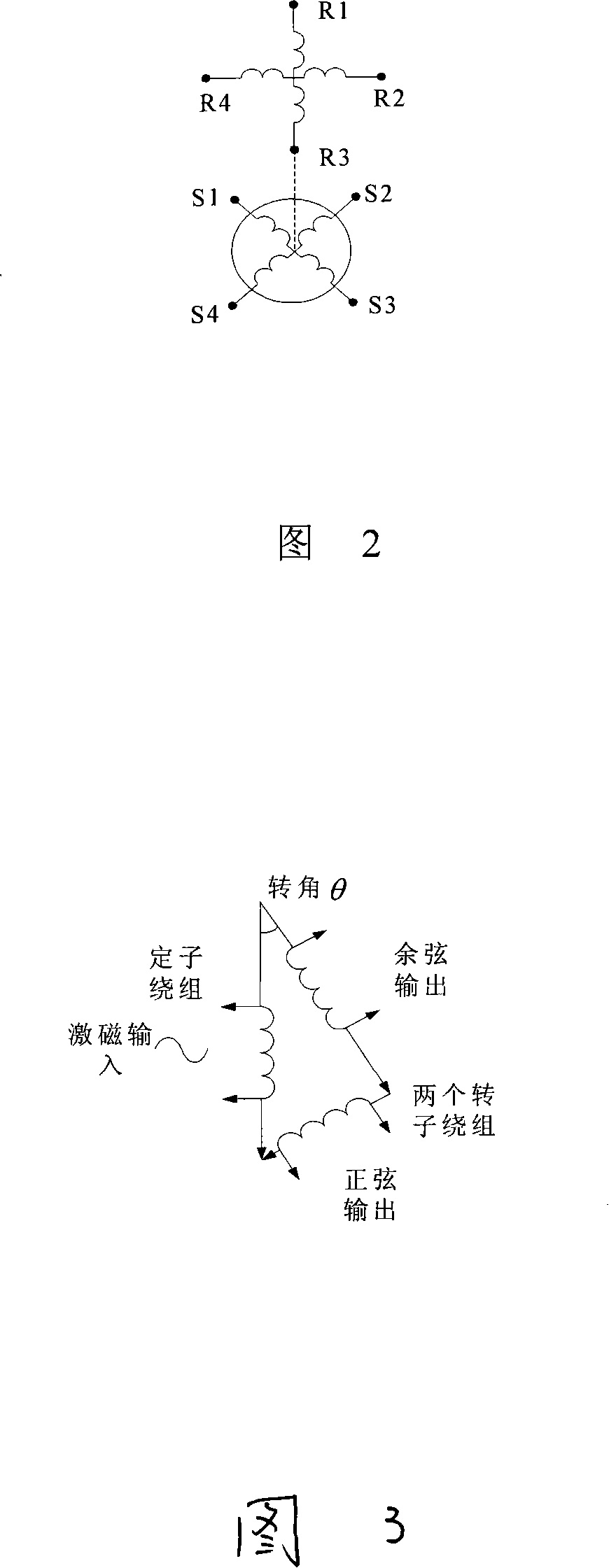

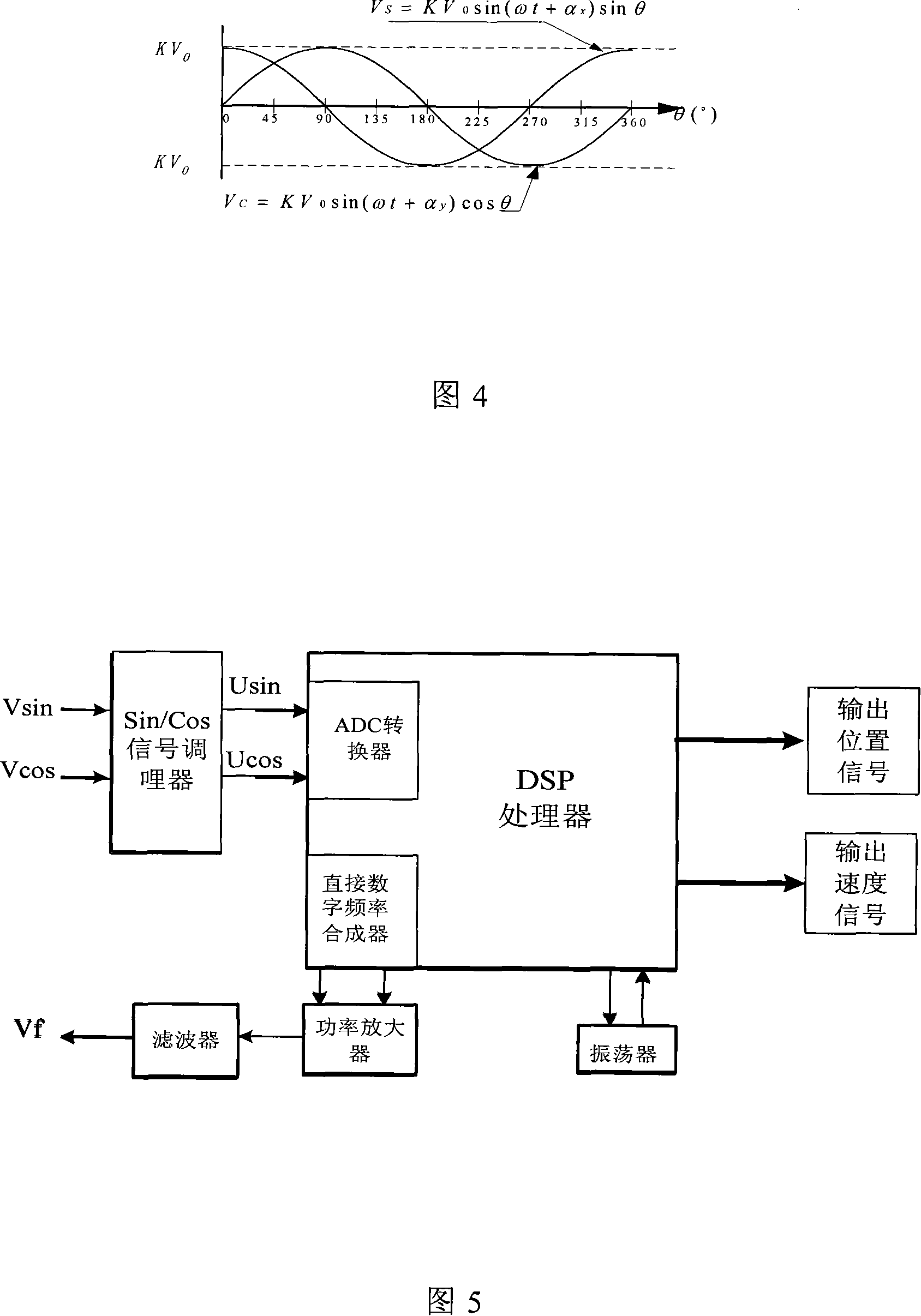

[0076] Example 1. Refer to Figures 1-15. A multi-turn absolute rotary encoder based on a rotary transformer. The signal processing circuit of the rotary encoder includes a microprocessor, a programmable controller, a memory, an optical couple and an RS485 interface chip; the rotary encoder uses a rotary transformer as a shaft angular displacement sensor , with DSP as the core processor to build the axis angle decoding circuit, the direct digital frequency synthesis circuit in the form of a numerically controlled oscillator generates a sine wave with controllable frequency and phase, which is directly used as the excitation signal of the resolver through the power amplifier and filter circuit; After the resolver signal passes through the electronic transformer matching circuit, it is sent to the A / D conversion. After oversampling, digital filtering and digital signal extraction processing, the sine and cosine values of the actual angle of the two channels are obtained. The PI...

Embodiment 2

[0077] Example 2. In the rotary encoder described in Embodiment 1, the rotary encoder adopts an integrated structural frame and is packaged in a metal aluminum shell, and the resolver is completely isolated from the encoding circuit in a sealed manner.

Embodiment 3

[0078] Example 3. In the rotary encoder described in embodiment 1 or 2, the output data of the rotary encoder adopts gray code or binary mode, and is output in the form of RS485, and an optical couple is used to isolate the input clock from the internal circuit, and simultaneously in the input and output circuits Lightning protection installed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com