Lithium ion power cell

A power battery, lithium ion technology, applied in battery electrodes, secondary batteries, battery pack components, etc., can solve the problems of high power, high energy, low active material specific efficiency, low weight specific energy, etc. The effect of wide operating temperature range, long storage life and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

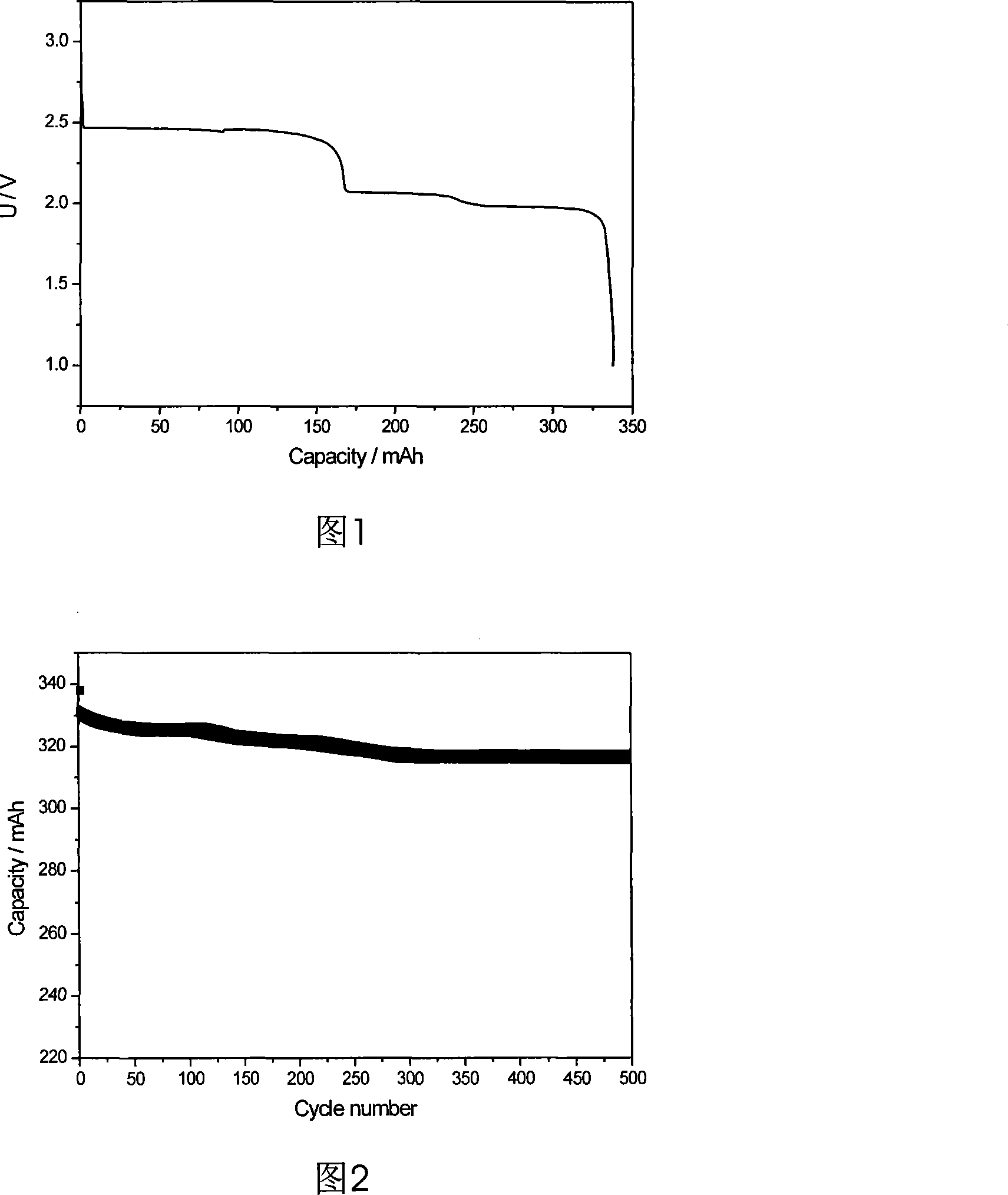

Embodiment 1

[0033] Example 1: 13 μm Li 4 Ti 5 o 12 , acetylene black, and polyvinylidene fluoride dissolved in N-methylpyrrolidone were put into a mixer according to a mass ratio of 90:5:5, and stirred at 150 rpm for 12 hours to obtain the required negative electrode slurry. Put the negative electrode slurry on a pulper, coat it on a 10μm copper foil, bake it at 130°C for 6 hours, roll it under a pressure of 20MPa, cut it according to a certain size of 270mm×42.5mm, and make it into a surface density 230g / cm 2 the negative pole piece. 13 μm Li 3 V 2 (PO 4 ) 3 , acetylene black, and polyvinylidene fluoride dissolved in N-methylpyrrolidone were put into a mixer according to a mass ratio of 88:7:5, and stirred at 100 rpm for 24 hours. Put the positive electrode slurry on a pulper, coat it on a 15μm aluminum foil, bake it at 150°C for 6 hours, roll it under a pressure of 25MPa, cut it according to a certain size of 320mm×41.5mm, and make a surface density of 210g / cm 2positive pole p...

Embodiment 2

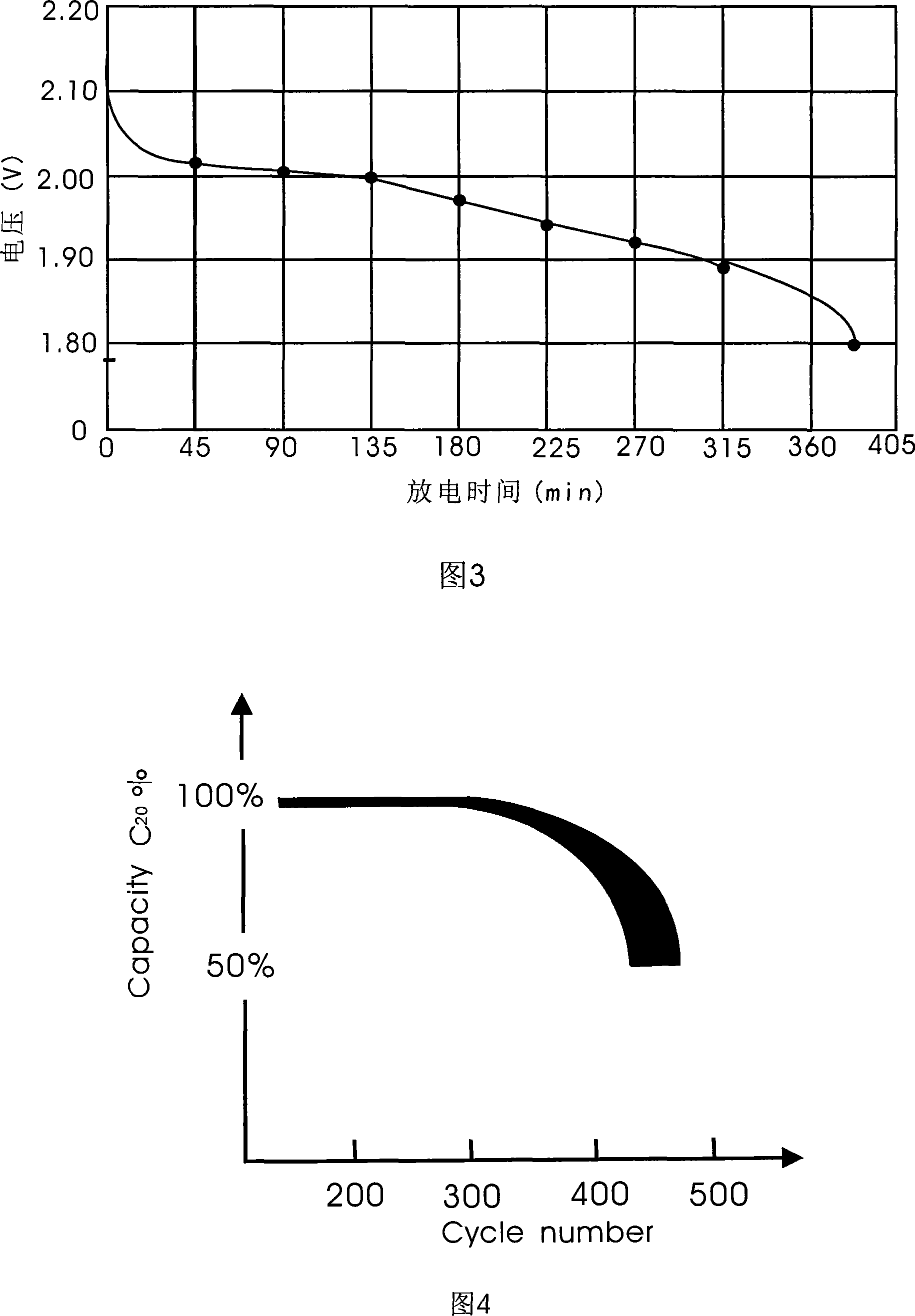

[0036] Example 2: 35 μm Li 4 Ti 5 o 12 , acetylene black and polyvinylidene fluoride dissolved in N-methylpyrrolidone were put into the mixer according to the mass ratio of 93:5:2, and stirred at 50 rpm for 24 hours to obtain the required negative electrode slurry. Put the negative electrode slurry on a pulper, coat it on a 20μm copper foil, and bake it at 100°C for 12 hours, at 10MPa / M 2 Rolling under a certain pressure, cut according to a certain size of 270mm×42.5mm, and made into a surface density of 230g / cm 2 the negative pole piece. 35 μm Li 3 V 2 (PO 4 ) 3 , acetylene black, and polyvinylidene fluoride dissolved in N-methylpyrrolidone were put into a mixer according to the ratio of 90:7:3, and stirred at 80 rpm for 24 hours. Put the positive electrode slurry on a pulper, coat it on a 12μm aluminum foil, bake it at 120°C for 12 hours, roll it under a pressure of 25MPa, cut it according to a certain size of 320mm×41.5mm, and make a surface density of 210g / cm 2 p...

Embodiment 3

[0039] Example 3: 25 μm Li 4 Ti 5 o 12 , conductive graphite and polytetrafluoroethylene aqueous solution were put into the mixer according to the mass ratio of 91:4:5, and stirred at 50 rpm for 24 hours to obtain the required negative electrode slurry. Put the negative electrode slurry on a pulper, coat it on a 20μm copper foil, and bake it at 100°C for 12 hours, at 10MPa / M 2 Rolling under a certain pressure, cut according to a certain size of 270mm×42.5mm, and made into a surface density of 230g / cm 2 the negative pole piece. 25 μm Li 3 V 2 (PO 4 ) 3 , conductive graphite and polytetrafluoroethylene aqueous solution were put into the mixer according to the ratio of 89:6:5, and stirred at 80 rpm for 24 hours. Put the positive electrode slurry on a pulper, coat it on a 12μm aluminum foil, bake it at 120°C for 12 hours, roll it under a pressure of 25MPa, cut it according to a certain size of 320mm×41.5mm, and make a surface density of 210g / cm 2 positive pole piece. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com