Method for preparing organic molecule device of crossing structure

A molecular device and organic technology, applied in the field of the preparation of cross-structured organic molecular devices, can solve the problems of large feature size, low integration, limited yield, etc., and achieve the effects of small feature size, large depth of focus, and short wavelength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

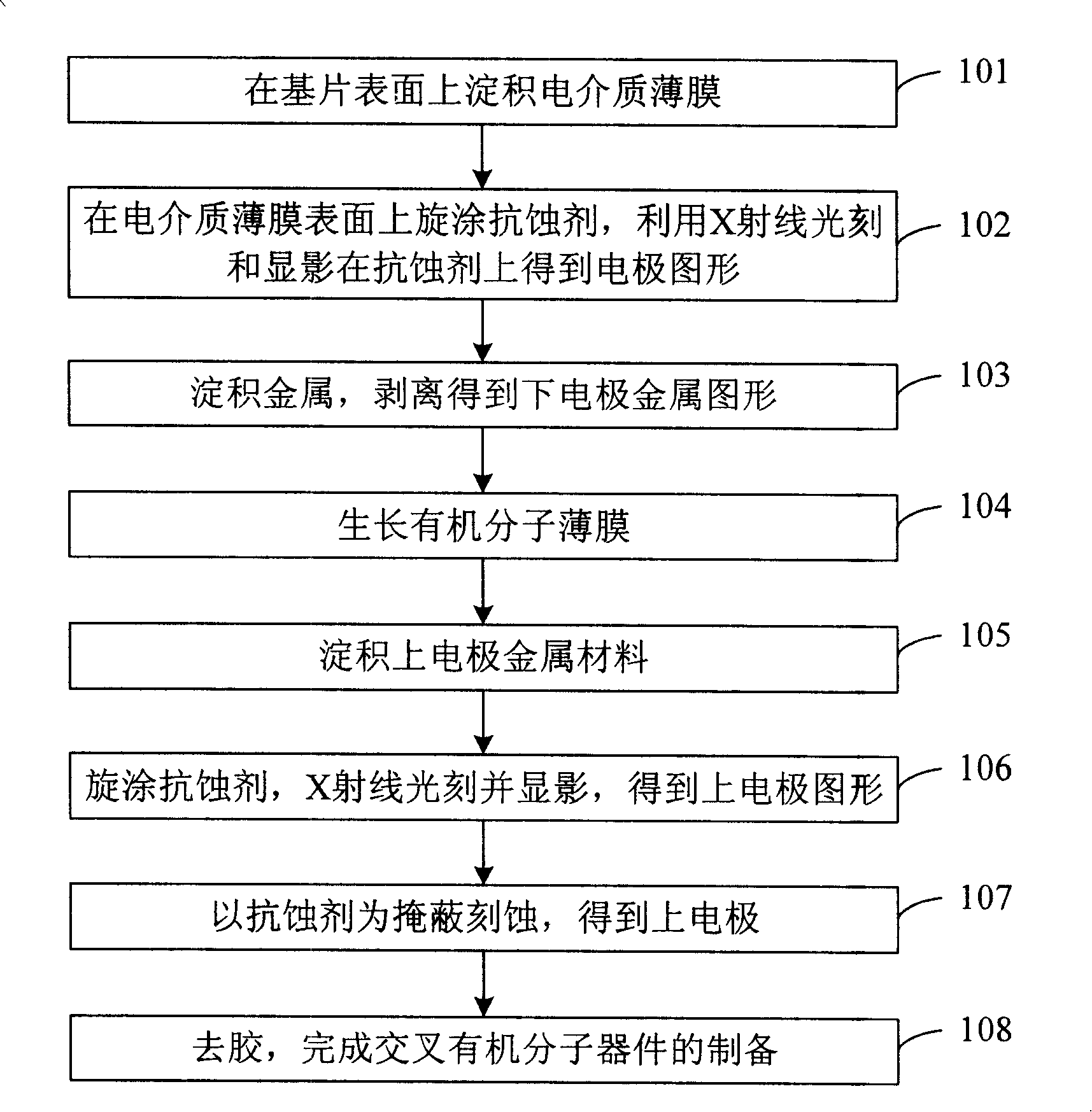

[0045] As shown in Figure 2, Figure 2 is a process flow chart for preparing a cross-structure organic molecular device according to an embodiment of the present invention, the method includes the following steps:

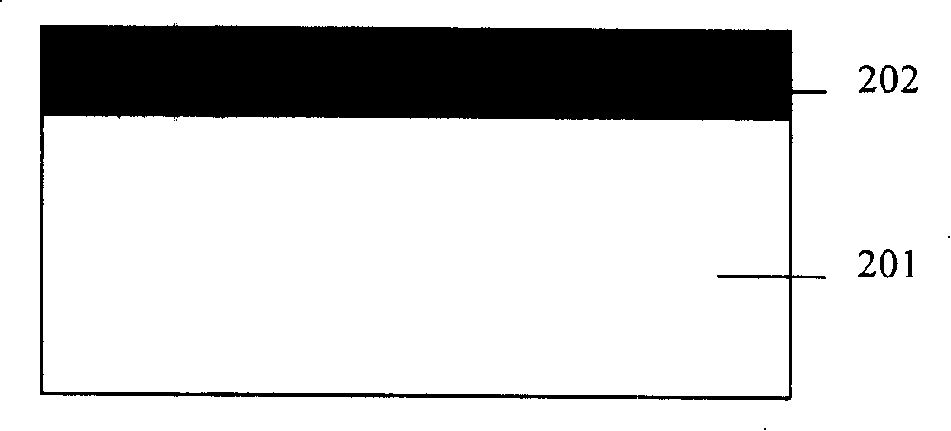

[0046] 1. If Figure 2-1 As shown, a dielectric film 202 is deposited on the surface of a substrate 201, and the dielectric film 202 is obtained by chemical vapor deposition or oxidation.

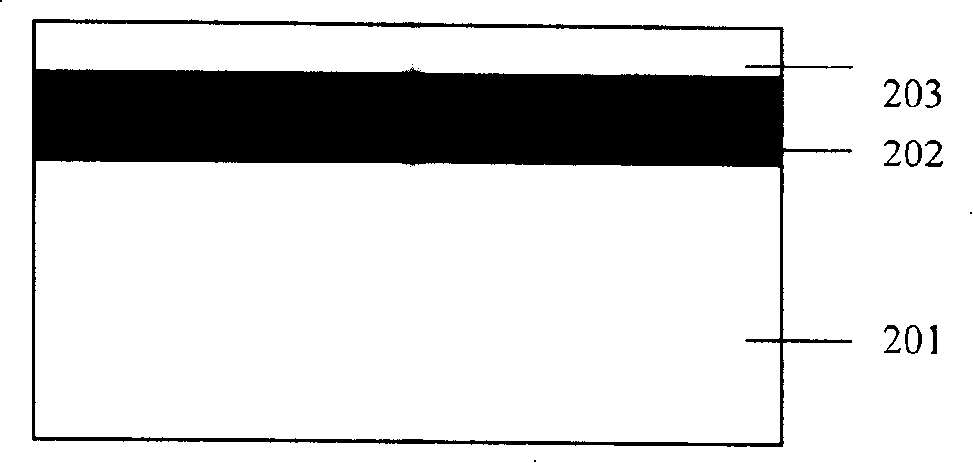

[0047] 2. If Figure 2-2 As shown, the PMMA resist 203 is spin-coated on the surface of the film 202, and pre-baked with a hot plate or an oven.

[0048] 3. If Figure 2-3 As shown, the resist lower electrode pattern 204 is obtained after X-ray lithography and development.

[0049] 4. If Figure 2-4 As shown, the metal 205 is electron beam evaporated, and the bottom electrode metal is chromium / gold.

[0050] 5. If Figure 2-5 As shown, the lower electrode 206 is obtained by ultrasonic peeling with acetone, ethanol, and deionized water.

[0051] 6. If Figure 2-6 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com