Metal-ceramic composite substrate and method for manufacturing same

A ceramic composite and metal substrate technology, applied in the direction of semiconductor lasers, printed circuits, lasers, etc., can solve the problems of poor heat dissipation, high cost, and poor yield, and achieve small temperature rise, improved heat dissipation, and reduced thermal resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0093] Hereinafter, the present invention will be described in more detail based on examples.

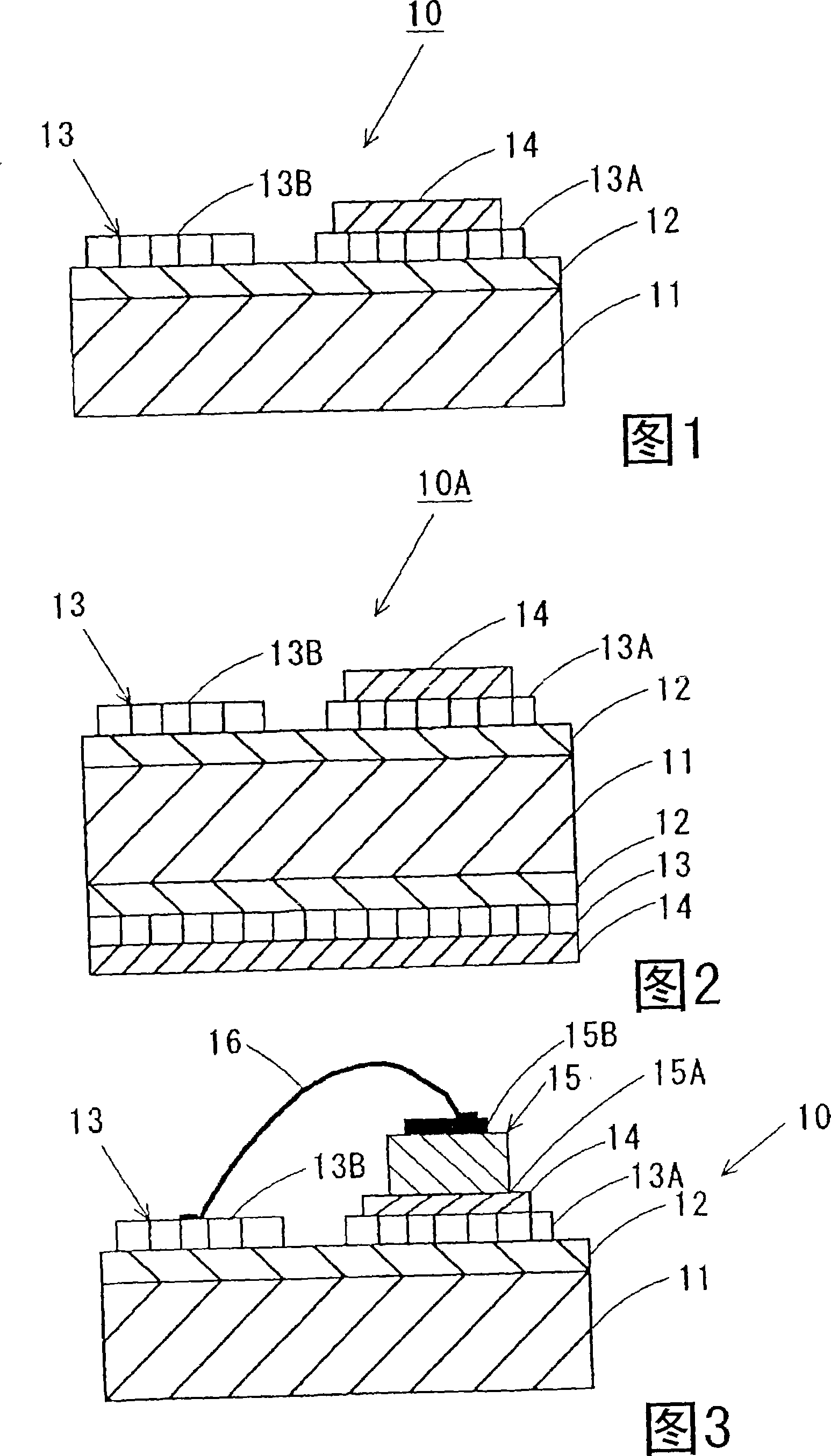

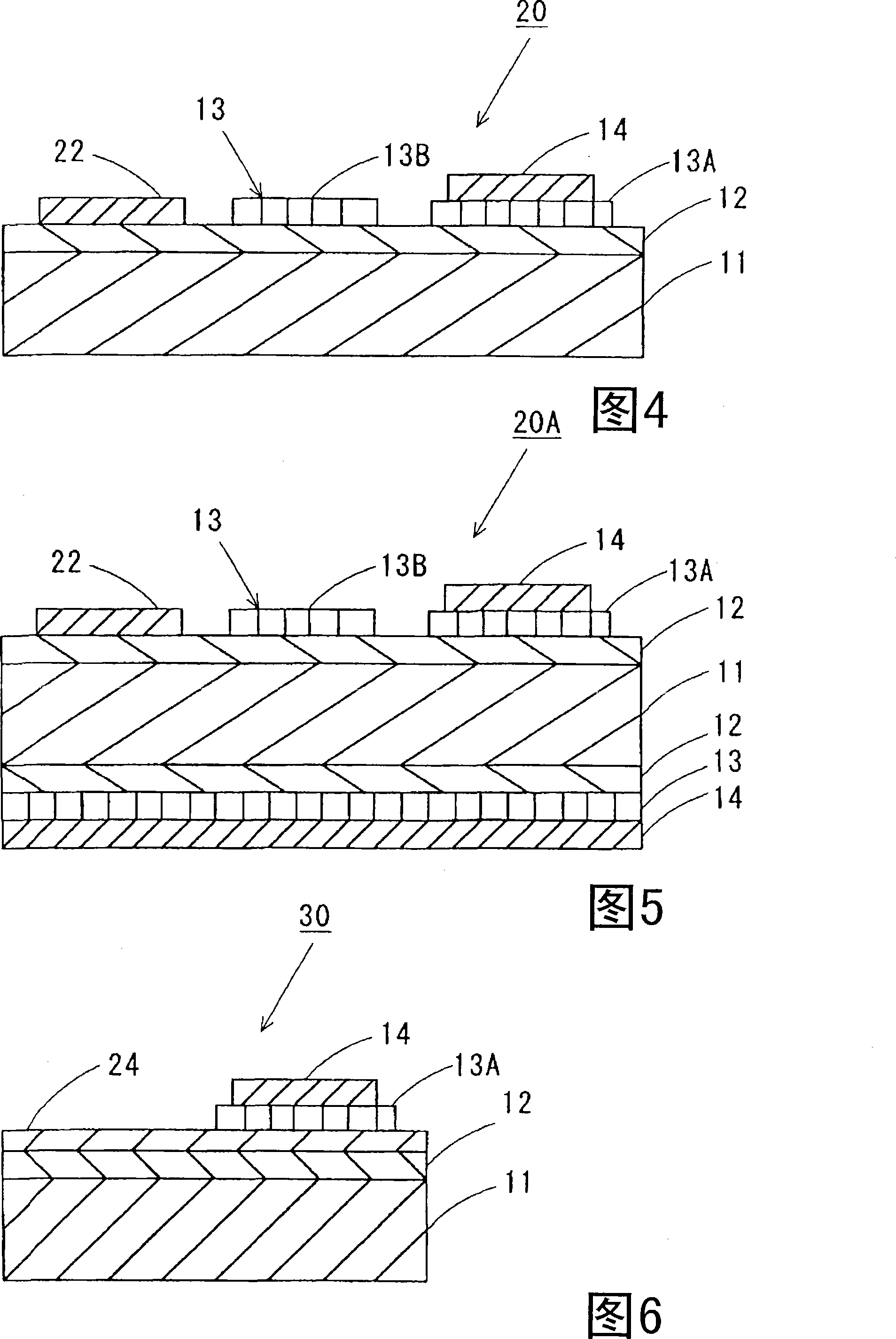

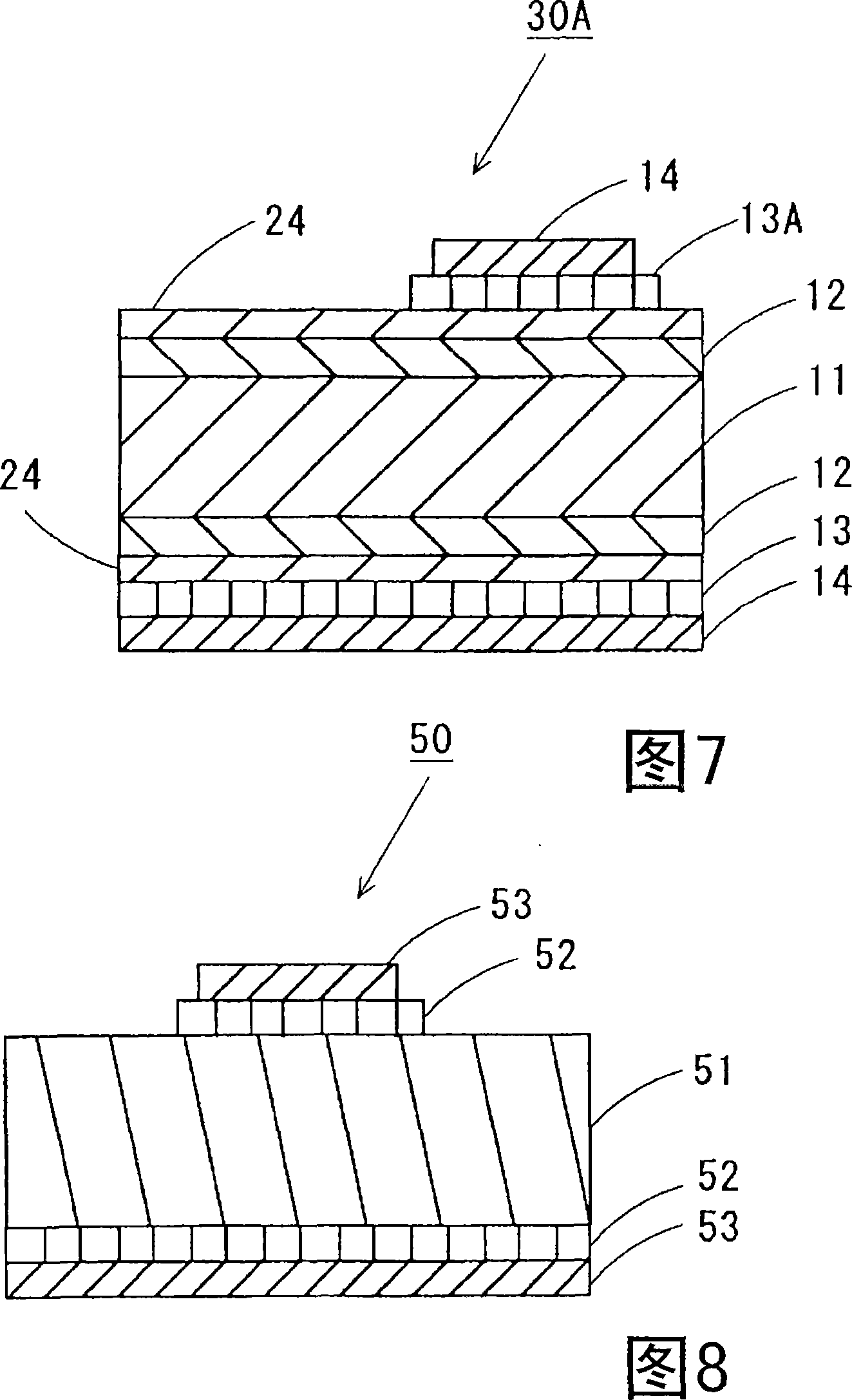

[0094] First, a method of manufacturing the metal-ceramic composite substrate 30A of the example will be described.

[0095] Both surfaces of the metal substrate 11 made of Cu with a size of 50 mm x 50 mm, a thickness of 300 μm, and a thermal conductivity of 300 W / mK were cleaned to perform surface cleaning. A ceramic layer 12 made of AlN with a thickness of 10 μm. As the PVD method, a sputtering apparatus is used. Al is used as a target, and further, an AlN thin film 12 is deposited by simultaneously supplying nitrogen gas. The thermal conductivity of this AlN thin film was 200 W / mK.

[0096] Next, on the entire front and rear surfaces of the AlN thin film 12, Ti was deposited as a ceramic layer protective film 24 with a thickness of 0.05 μm and a thermal conductivity of 20 W / mK by a vacuum deposition apparatus.

[0097] For patterning by photolithography, resist is uniformly c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com