Fixing method for bimetal salt

A bimetallic salt, metal salt technology, applied in chemical instruments and methods, chemical/physical processes, catalyst activation/preparation, etc., can solve problems such as bimetallic salts that have not yet been seen, and achieve stable activity, not easy to leak, and catalyst loading. high volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

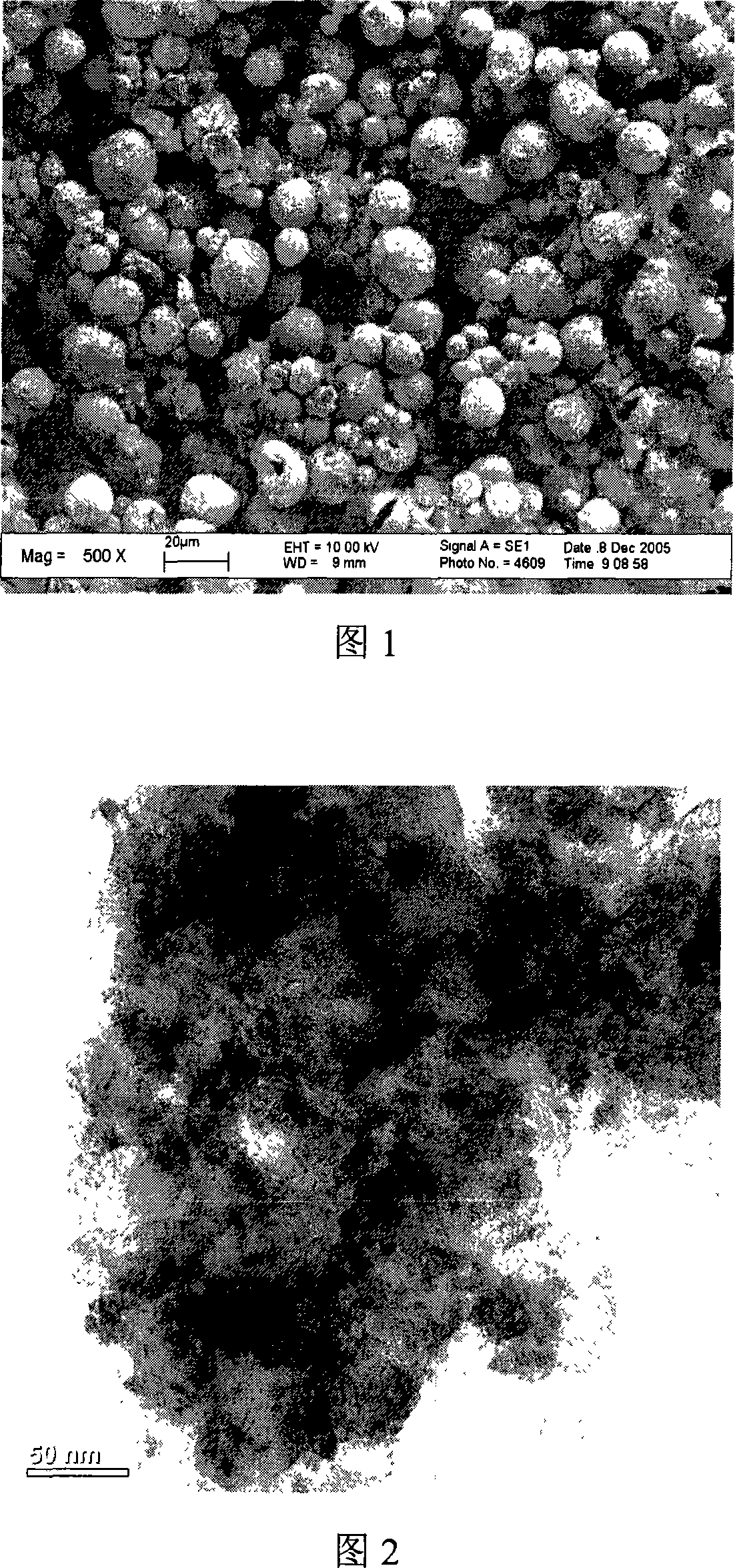

[0024] Weigh 0.6g CuCl 2 and 0.15g MnCl 2 Dissolve in 10mL water to form solution A; weigh 6.0g toluene 2,4-diisocyanate and 3.5g sorbitan monooleate (Span-80) and dissolve in 40mL cyclohexane to prepare solution B; 25°C Add solution A to solution B under mechanical stirring, continue to stir for 20 minutes, add 0.5mL triethylamine (TEA), react for 5h, then add 0.8mL TEA, react for 24h, and the reaction system is centrifuged to obtain the required microcapsules. The microcapsules were washed and filtered with acetone, 95% ethanol, deionized water and acetone successively, and dried at room temperature to obtain bimetallic copper chloride and manganese chloride microcapsules, abbreviated as (CuCl 2 +MnCl 2 ) EnCat. The morphology of the microcapsules and the distribution of metal salts on the walls of the microcapsules were characterized by scanning electron microscopy and transmission electron microscopy. The scanning electron microscope picture shown in Figure 1 shows tha...

Embodiment 2

[0026] Weigh 0.15g MnCl 2 and 1.2g CoCl 2 Dissolve in 30mL water to form solution A; weigh isophor diisocyanate (15g) and 7g Span-80 and dissolve in 60mL cyclohexane to prepare solution B; add solution A to solution B under mechanical stirring at 25°C, continue Stir for 20min, add 0.7mL TEA, react for 5h, then add 1.3mL TEA, react for 24h, the reaction system is centrifuged to obtain the required microcapsules, and the obtained microcapsules are successively washed with acetone, 95% ethanol, deionized water and acetone. filter, and dry at room temperature to obtain bimetallic cobalt chloride and manganese chloride microcapsules, abbreviated as (MnCl 2 +CoCl 2 ) EnCat. Transmission electron microscope pictures show that the metal in the prepared microcapsules is distributed in nanometer state on the microcapsules.

Embodiment 3

[0028] Weigh 0.2g CuCl 2 and 0.6MnCl 2 Dissolve in 10mL water to form solution A; weigh toluene 2,4-diisocyanate (6.0g) and Span-80 (3.5g) and dissolve in 40mL cyclohexane to obtain solution B; add solution A under mechanical stirring at 25°C Add TEA (0.5mL) to solvent B, continue to stir for 20min, add TEA (0.8mL) after 5h of reaction, react for 24h, and obtain the desired microcapsules through centrifugation of the reaction system. % ethanol, deionized water and acetone washing and suction filtration, drying at room temperature to obtain bimetallic palladium chloride and nickel chloride microcapsules, abbreviated as (CuCl 2 +NiCl 2 ) EnCat. Transmission electron microscope pictures show that the metal in the prepared microcapsules is distributed in nanometer state on the microcapsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com