Membrane bioreactor capable of realizing synchronous nitration denitrification denitrogenation function

A membrane bioreactor, synchronous nitrification technology, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc. High volume, small footprint, and the effect of reducing membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

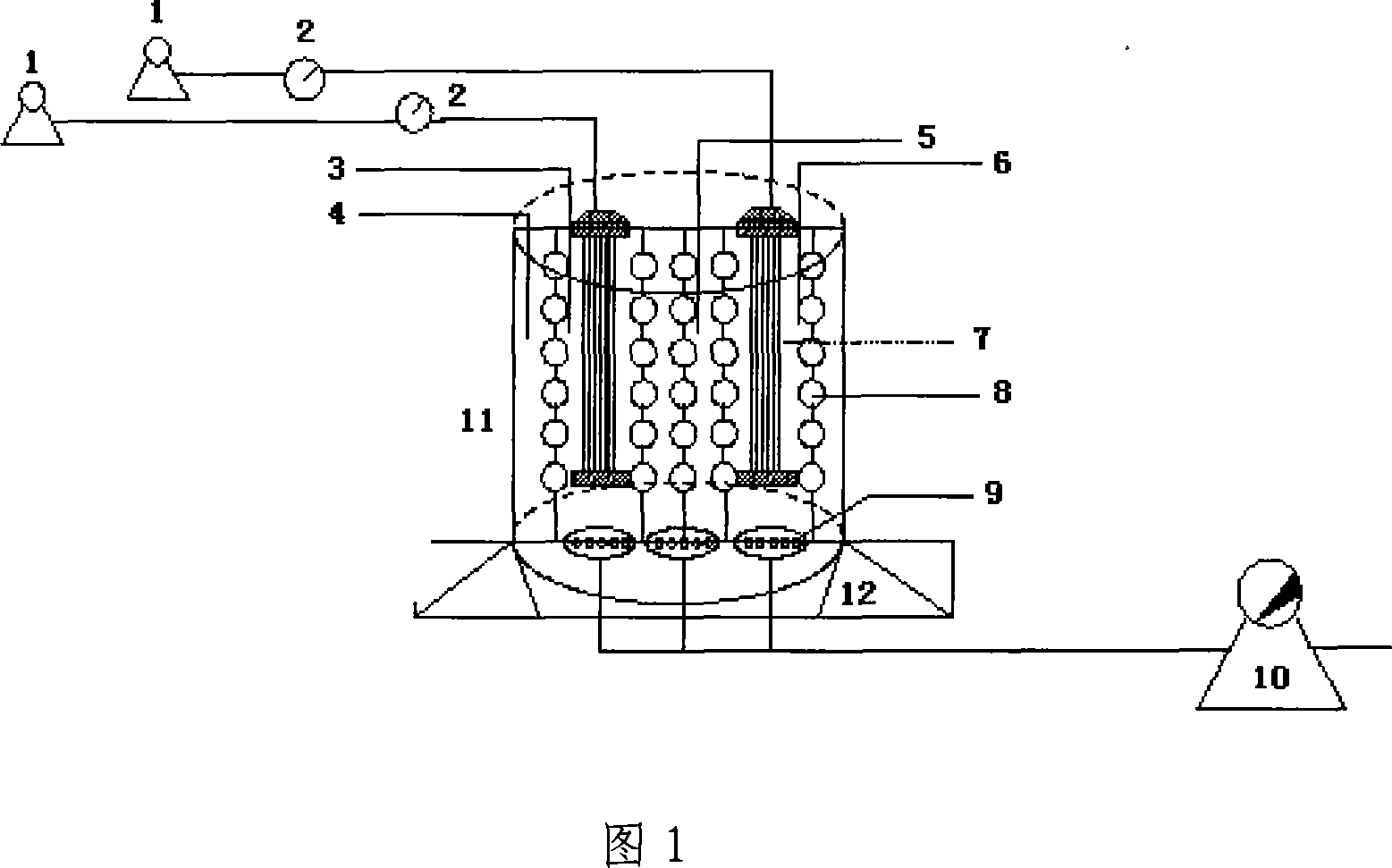

[0019] Including reactor system, membrane module, dissolved oxygen electrode, pH electrode and other on-line monitoring components. The reactor is equipped with a membrane module, which is connected with a water pressure gauge and a vacuum pump in sequence. The reactor is equipped with a water inlet pipe and a dissolved oxygen electrode. , a thermometer and a pH electrode, spherical elastic fillers 8 are evenly arranged around the membrane module 7 in the reactor column 11, and a microporous aerator 9 is arranged at the bottom of the reactor column 11, and the microporous aerator 9 is connected with the air The pumps 10 are connected to ensure uniform aeration of the reactor column 11 and provide the required concentration of dissolved oxygen. The spherical elastic filler 8 has a specific surface area of 5m 2 / g, the pore size is 100μm, the porosity is 50%, the membrane in the membrane module is a hollow fiber ultrafiltration membrane, the nominal pore size of the ultrafiltr...

Embodiment 2

[0027] The difference from the example is that:

[0028] According to Figure 1, it is processed into an effective volume of 0.5m 3 The column body 11 of the MBR reactor and a set of membrane modules are configured, and the spherical elastic packing 8 is evenly arranged with other spaces in the MBR. The spherical elastic packing (8) is connected in series from top to bottom to form a whole, and is fixed in the reactor cylinder 11. In addition, the MBR system is still equipped with dissolved oxygen, pH, temperature online monitoring control elements. Other equipment such as vacuum pumps, air pumps, aerators, etc. are selected according to the corresponding models.

[0029]The influent of the MBR is the effluent of the bioactive filter of the coking plant, and the inoculation sludge in the MBR is taken from the sludge in the biological treatment system of the coking wastewater on an engineering scale. Other reactor operating parameters are: the sludge residence time in the MBR...

Embodiment 3

[0033] The difference from the examples is that the spherical elastic filler 8 has a specific surface area of 20m 2 / g, the porosity is between 70%, and the carrier pore diameter is 1000 μm. The operating parameters of the membrane bioreactor are: sludge residence time in the reactor: 5-10d, operating temperature: 10-30°C; pH in the reactor: 6.5-8.5; dissolved oxygen concentration: 0.2-3.0mg / L. The membrane in the membrane module is a hollow fiber ultrafiltration membrane, the nominal pore size of the ultrafiltration membrane is 0.05μm, and the membrane area is 25m 2 , the flux is 301 / m 2 .h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com