Tungsten-containing super large mesoporous foam catalyst for synthesizing glutaraldehyde and manufacturing method thereof

A catalyst and glutaraldehyde technology, applied in molecular sieve catalysts, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of less than 500 tons of production capacity, difficult separation of catalysts and products, and low yield of glutaraldehyde. Achieve the effects of improving efficiency, excellent catalytic performance, and simplifying the original homogeneous process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

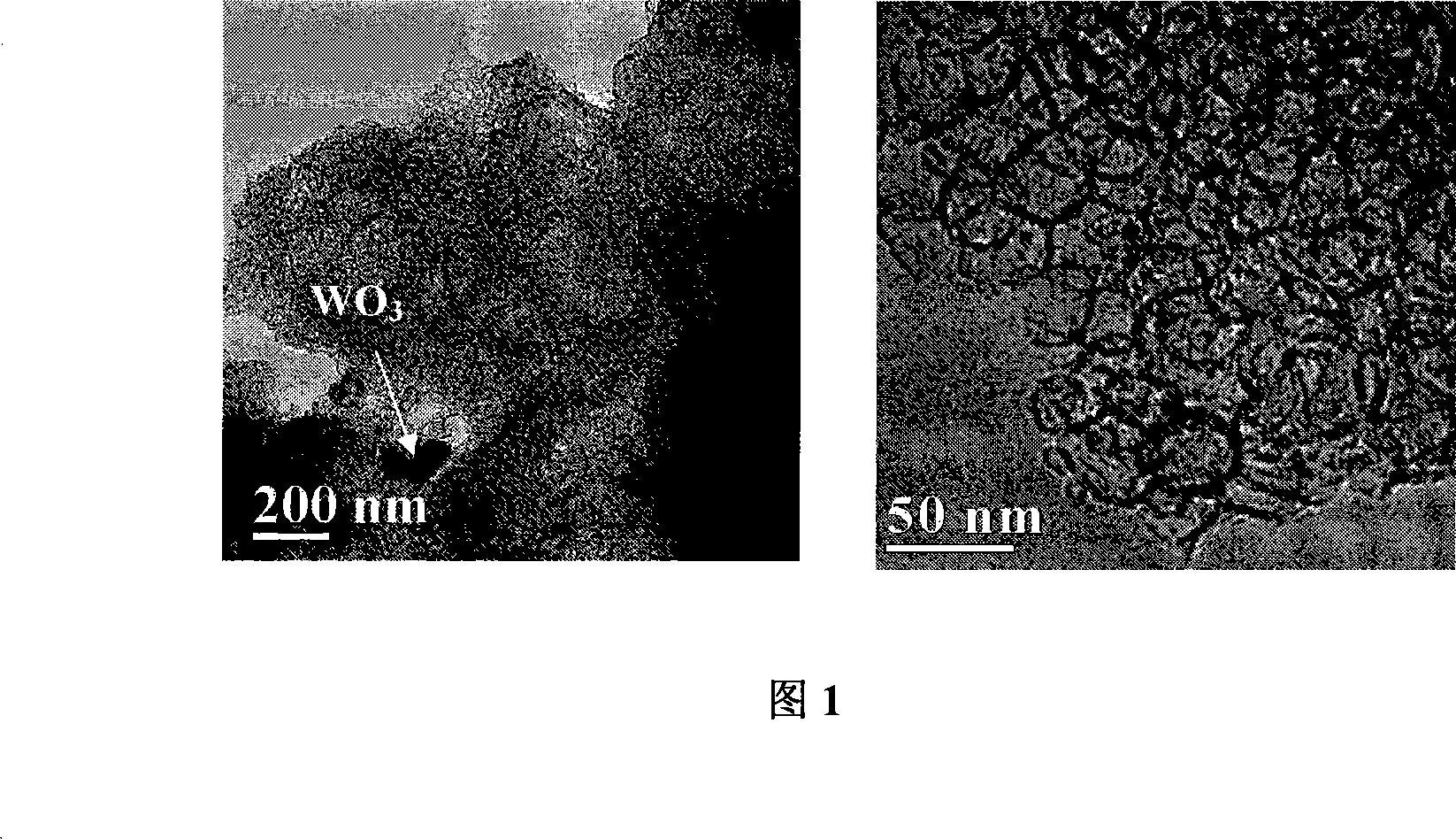

Image

Examples

Embodiment 1

[0019] Example 1: In a 40°C oil bath, add 2.0g of P123 template agent to 75mL of 1.6mol / L hydrochloric acid solution, stir for 4 hours to fully dissolve P123, then add 2.0g of TMB expansion agent, continue stirring for 1 hour, and then add 4.4 g tetraethyl orthosilicate, when stirring for 1 h, add 3 mL of aqueous solution containing 0.161 g of sodium tungstate, and continue stirring for 24 h. It was crystallized at 100°C for 1 day, taken out, filtered, washed, dried, slowly heated to 500°C in air atmosphere, calcined for 8 hours, granulated, sieved with 40-60 mesh, and activated at 800°C for 3 hours to obtain 1# catalyst.

Embodiment 2

[0020] Example 2: In an oil bath at 40°C, add 2.0g of P123 template agent to 75mL of 1.6mol / L hydrochloric acid solution, stir for 4 hours to fully dissolve P123, then add 2.0g of TMB expansion agent, continue stirring for 1 hour, and then add 4.4 g tetraethyl orthosilicate, when stirring for 1 h, add 6.2 mL of aqueous solution containing 0.321 g of sodium tungstate, and continue stirring for 24 h. Remaining with example 1, be recorded as 2# catalyst.

Embodiment 3

[0021] Example 3: In an oil bath at 40°C, add 2.0g of P123 template agent to 75mL of 1.6mol / L hydrochloric acid solution, stir for 4 hours to fully dissolve P123, then add 2.0g of TMB expansion agent, continue stirring for 1 hour, and then add 4.4 g tetraethyl orthosilicate, when stirring for 1 h, add 10 mL of aqueous solution containing 0.482 g of sodium tungstate, and continue stirring for 24 h. Remaining with example 1, be recorded as 3# catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com