Method for preparing hot melt adhesive net film

A technology of hot-melt adhesive and glue omentum, which is applied in the direction of melt spinning, film/sheet adhesive, net, etc., can solve the problems of unfavorable development of circular economy, many hot-melt collagen materials, and high cost. Achieve the effect of reducing production cost, low production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

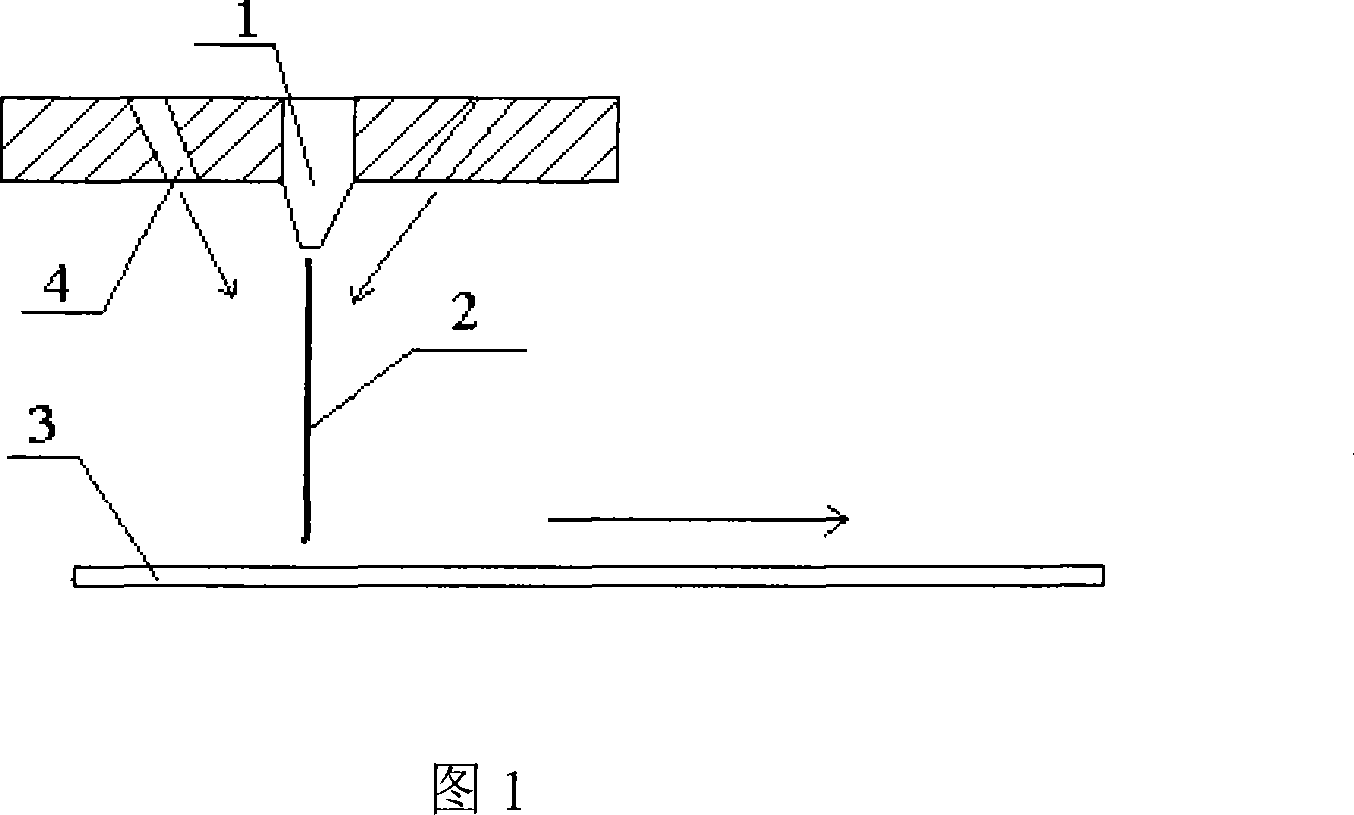

Image

Examples

Embodiment 1

[0026] Weigh a total of 10kg of copolyamide hot melt adhesive (melt index: 15.4g / 10min) model 6120, first dry it at -20°C for 2.0 hours, then enter it into a vacuum drum for drying and water removal for 2.0 hours, then take it out for measurement Moisture content, when the weight content of the water content is less than 0.8%, put it into a single screw and melt it at 215°C, and add the nucleating agent ultra-fine talcum powder with an average particle size of 8μm according to 0.01% of the net weight of the hot melt adhesive, and mix well Then enter the melt pump and pressurize to 10.0MPa, spray out through a nozzle with an aperture of 0.25mm, control the pressure of the compressed air to 0.45MPa, adjust the flow rate so that the spinning line speed is 6.0m / min, and the hot melt adhesive sprayed out The wire swings on the conveyor belt with a moving speed of 4.50m / min to form a mesh membrane, the average pore size of the mesh is 80 mesh, and the average gram weight is 20g / m 2 ...

Embodiment 2

[0029] Weigh 10kg of copolyamide hot-melt adhesive (melt index: 20.3g / 10min) with brand 6200, firstly dry it at -20°C for 2.0h, then put it into a vacuum drum for drying and dehydration for 2.0h, then take it out for measurement Moisture content, when the water weight content is less than 1.0%, put it into a single screw and melt it at 205°C, and add the nucleating agent ultrafine calcium carbonate with an average particle size of 6μm according to 0.05% of the net weight of the hot melt adhesive, and mix it evenly Enter the melt pump and pressurize to 8.0MPa, spray out through a nozzle with an aperture of 0.20mm, control the pressure of the compressed air to 0.45MPa, adjust the flow rate so that the spinning line speed is 8.0m / mim, and the hot melt adhesive sprayed out The silk forms a mesh membrane on a pendulum with a moving speed of 4.0m / h. The average pore size of the mesh is 90 mesh, and the average gram weight is 28g / m 2 .

[0030] The bevel angle of the compressed air ...

Embodiment 3

[0032] Weigh a total of 10kg of copolyamide hot melt adhesive (melt index: 18.6g / 10min) model 6300, first dry it at -20°C for 2.0 hours, then put it into a vacuum drum for drying and water removal for 2.0 hours, then take it out for measurement Moisture content, when the moisture content is less than 0.8%, it can be put into a single screw and melted at 210°C, and the superfine calcium carbonate with a nucleating agent with an average particle size of 10μm is added according to 0.09% of the net weight of the hot melt adhesive, and mixed evenly Enter the melt pump and pressurize to 8.0MPa, spray out through the nozzle, control the pressure of compressed air to 0.5MPa, adjust the flow rate so that the spinning line speed is 12.0m / min, and the jetted hot-melt glue is moving at a speed of 3.8m / min pendulum forms a screen membrane, the average pore size of the mesh is 100 mesh, and the average weight is 50g / m 2 .

[0033] The bevel angle of the compressed air is 20°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

| Average weight | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com