Method for reducing propylene concentration of dry gas in catalytic cracking device absorption stabilizing system

A technology of absorption stabilization system and catalytic cracking unit, which is applied in the field of petroleum processing to achieve simple transformation, improve economic benefits, and reduce propylene content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

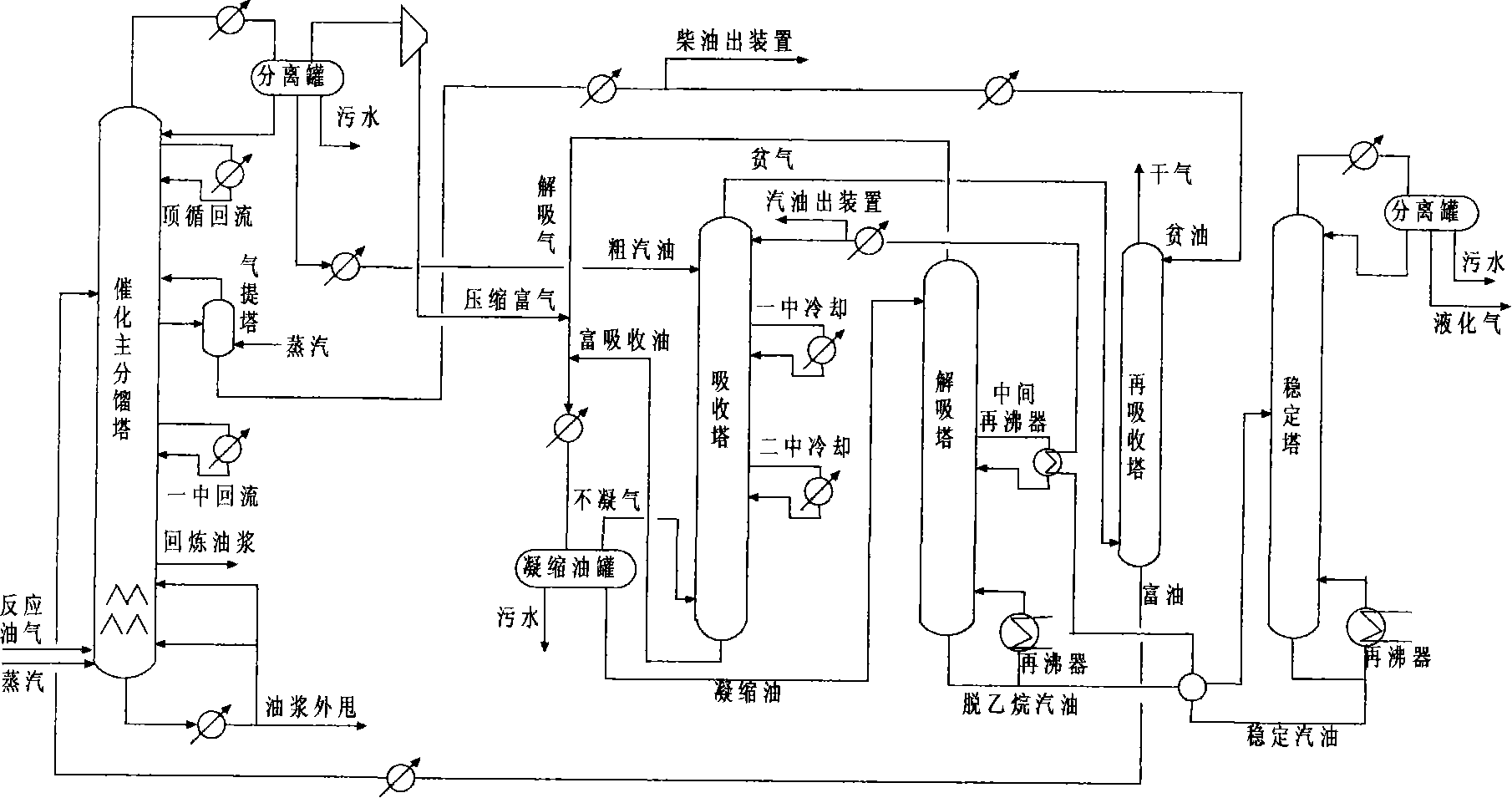

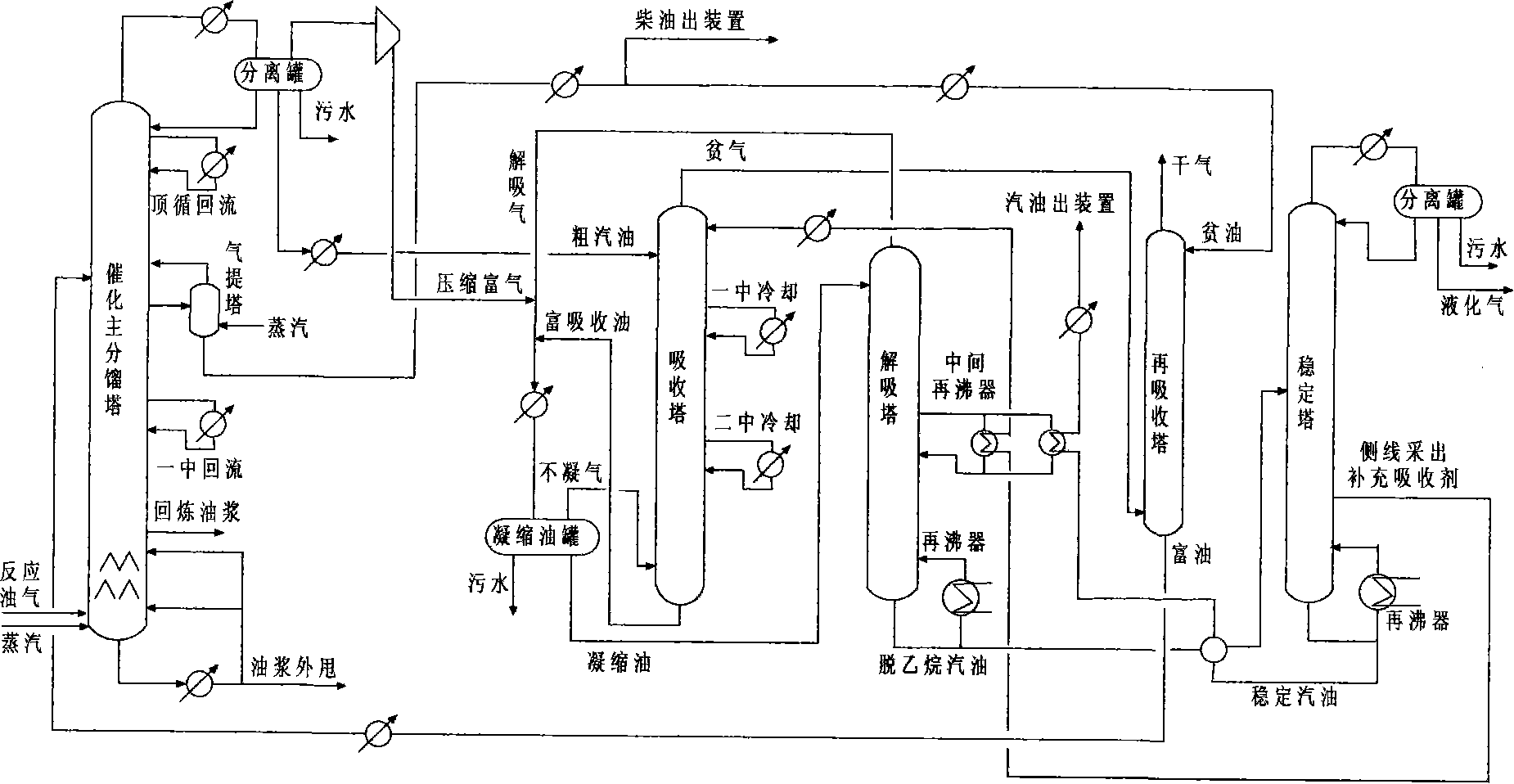

[0031] figure 2 For the technological process of the catalytic cracking unit fractionation and absorption stabilization system of the present embodiment, compared with the technological process flow of the catalytic cracking unit fractionation and absorption stabilization system of the comparative example, this embodiment has made the following improvements:

[0032] (1) Improvement of supplementary absorbent process

[0033]Open a side line at the third theoretical plate of the stabilizing tower (the first theoretical plate at the bottom of the stabilizing tower is numbered 1), and produce a stream of light gasoline, which first passes through the newly added desorption tower intermediate reboiler and desorption tower The mid-stage reflux heat exchange is then cooled to 40°C by a circulating water cooler, and then enters the top of the absorption tower as a supplementary absorbent, and at the same time cancels the process of supplementary absorbent entering the absorption to...

Embodiment 2

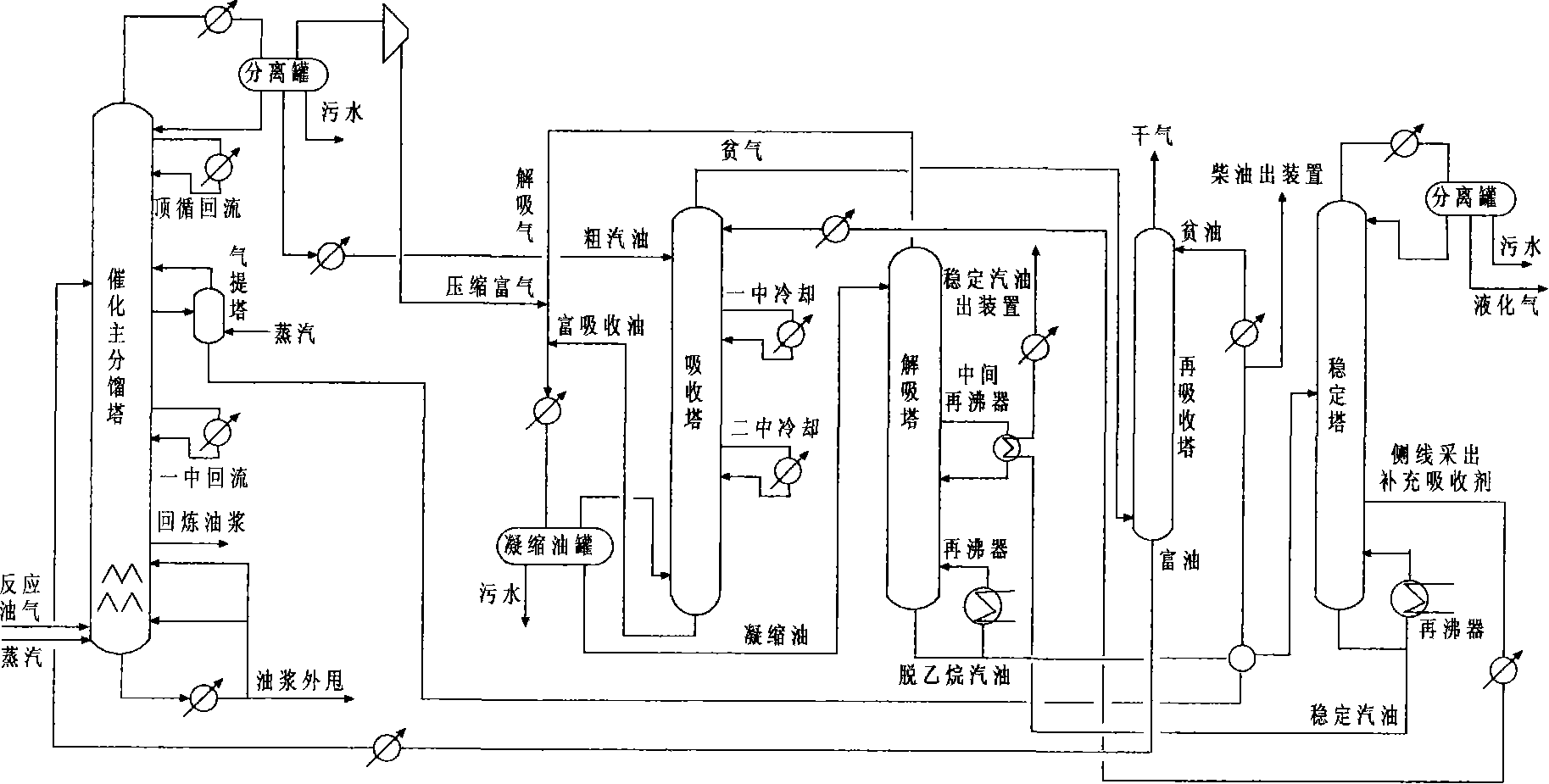

[0045] image 3 It is the process flow chart of the fractionation and absorption stabilization system of the catalytic cracking unit in this embodiment. The difference between this embodiment and embodiment 1 lies in the improvement of the heat exchange process, which is as follows:

[0046] (2) Improvement of heat transfer process

[0047] The heat exchange process of heating deethanized gasoline with diesel oil is as follows: the diesel oil extracted from the catalytic main fractionation tower is used to heat the deethanized gasoline at one time, and at the same time, the process of heating the deethanized gasoline with stabilized gasoline is canceled (that is, the stabilized gasoline first passes through the desorption tower and then boils again. The device and the middle section of the desorption tower are refluxed for heat exchange, and then cooled by circulating water, and then all of them are discharged from the device) The supplementary absorbent in the side line exch...

Embodiment 3

[0056] The difference between this embodiment and Example 1 is that the extraction position of the side line supplementary absorbent is changed from the third theoretical plate to the fifth theoretical plate and the temperature of the side line supplementary absorbent entering the absorption tower is changed from 40°C to 35°C. The rest of the process is the same. The effect of this embodiment is basically the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com