Double-layer collagen-chitosan sponges bracket and method of preparing the same

A technology of chitosan and chitosan solution, applied in medical science, prosthesis, etc., to increase the number of stops, promote cell proliferation, and reduce leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

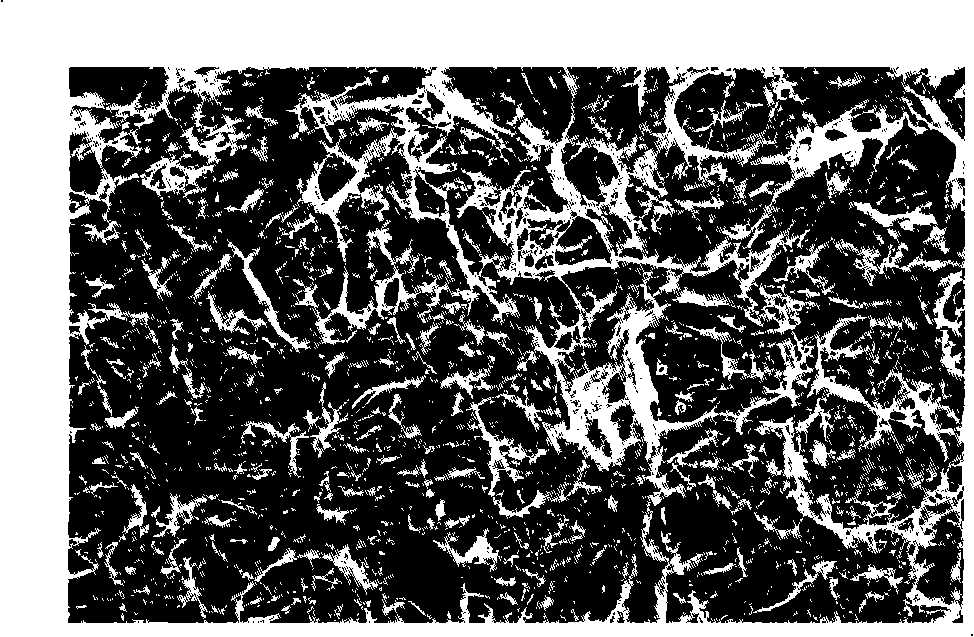

Embodiment 1

[0030]The collagen swelling solution and chitosan were dissolved in 0.05M acetic acid aqueous solution to obtain 0.2% (wt) collagen dispersion and chitosan dispersion and 0.8% (wt) collagen dispersion and chitosan dispersion. Collagen dispersion liquid and chitosan dispersion liquid of the same concentration were mixed at a mass ratio of 9:1 to obtain collagen-chitosan solutions with solid content of 0.8% and 0.2%. Pour 15 g of collagen-chitosan solution with a solid content of 0.8% into a glass petri dish with a diameter of 9 cm, keep the liquid level and place it in a -60 ° C refrigerator overnight, and then quickly move it into a freeze dryer for 40 hours. The freeze-dried sponge was placed between two smooth polytetrafluoroethylene plates, and pressed with a weight of 15kg for 24h. Soak the pressed sponge in 0.2% glutaraldehyde cross-linking solution, react at 4°C for 24 hours, and wash with distilled water, NaBH 4 Phosphate buffer solution, saturated NaCl solution and de...

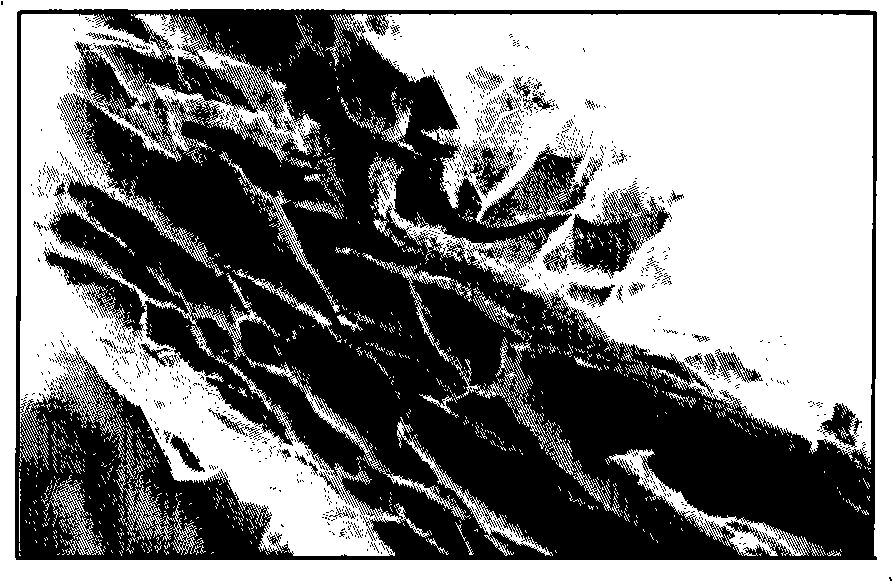

Embodiment 2

[0032] The collagen swelling solution and chitosan were dissolved in 0.5M acetic acid aqueous solution to obtain 0.2% (wt) collagen dispersion and chitosan dispersion and 0.8% (wt) collagen dispersion and chitosan dispersion. The collagen dispersion and the chitosan dispersion of the same concentration were mixed in a mass ratio of 8:2. Pour 10 g of collagen-chitosan solution with a solid content of 0.8% into a glass petri dish with a diameter of 6 cm, keep the liquid level and place it in a -60 ° C refrigerator overnight, and then quickly move it into a freeze dryer for 24 hours to freeze dry. The freeze-dried sponge was placed between two smooth polytetrafluoroethylene plates, and pressed with a weight of 15kg for 24h. Soak the laminated sponge in 0.25% glutaraldehyde cross-linking solution, react at 4°C for 12h, then soak with distilled water, NaBH4 phosphate buffer, saturated NaCI solution and deionized water, and freeze at -20°C After overnight, freeze-drying was carried...

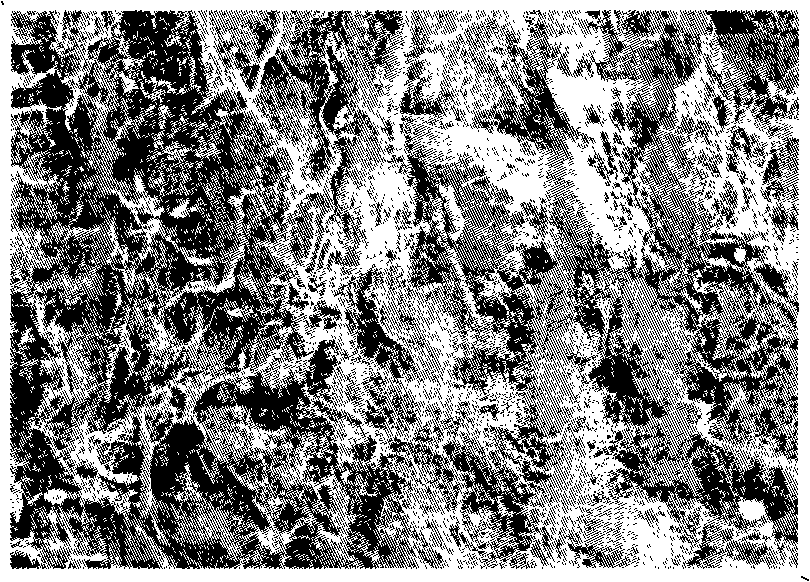

Embodiment 3

[0034] The collagen swelling solution and chitosan were dissolved in 1M acetic acid aqueous solution to obtain 0.3% (wt) collagen dispersion and chitosan dispersion and 0.7% (wt) collagen dispersion and chitosan dispersion. Collagen dispersion liquid and chitosan dispersion liquid of the same concentration were mixed at a mass ratio of 7:3 to obtain collagen-chitosan composite liquids with solid content of 0.7% and 0.3%. Pour 100g of collagen-chitosan complex solution with a solid content of 0.7% into a ceramic tray with a size of 28cm×18cm, keep the liquid level and place it in a -60°C refrigerator overnight, then quickly transfer it to a freeze dryer for 42 hours . The freeze-dried sponge was placed between two smooth polytetrafluoroethylene plates, and pressed with a weight of 15kg for 24h. Immerse the pressed sponge in 0.5% glutaraldehyde cross-linking solution, react at 4°C for 12 hours, wash with distilled water, NaBH 4 Phosphate buffer saline, saturated NaCl solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com