Process for comprehensive recovery of indium, cadmium, thallium and zinc from lead system smoke

A soot and new process technology, applied in the field of non-ferrous metal smelting, can solve the problems of using more equipment, wasting resources, and not considering recycling, and achieve the effect of reducing equipment investment and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

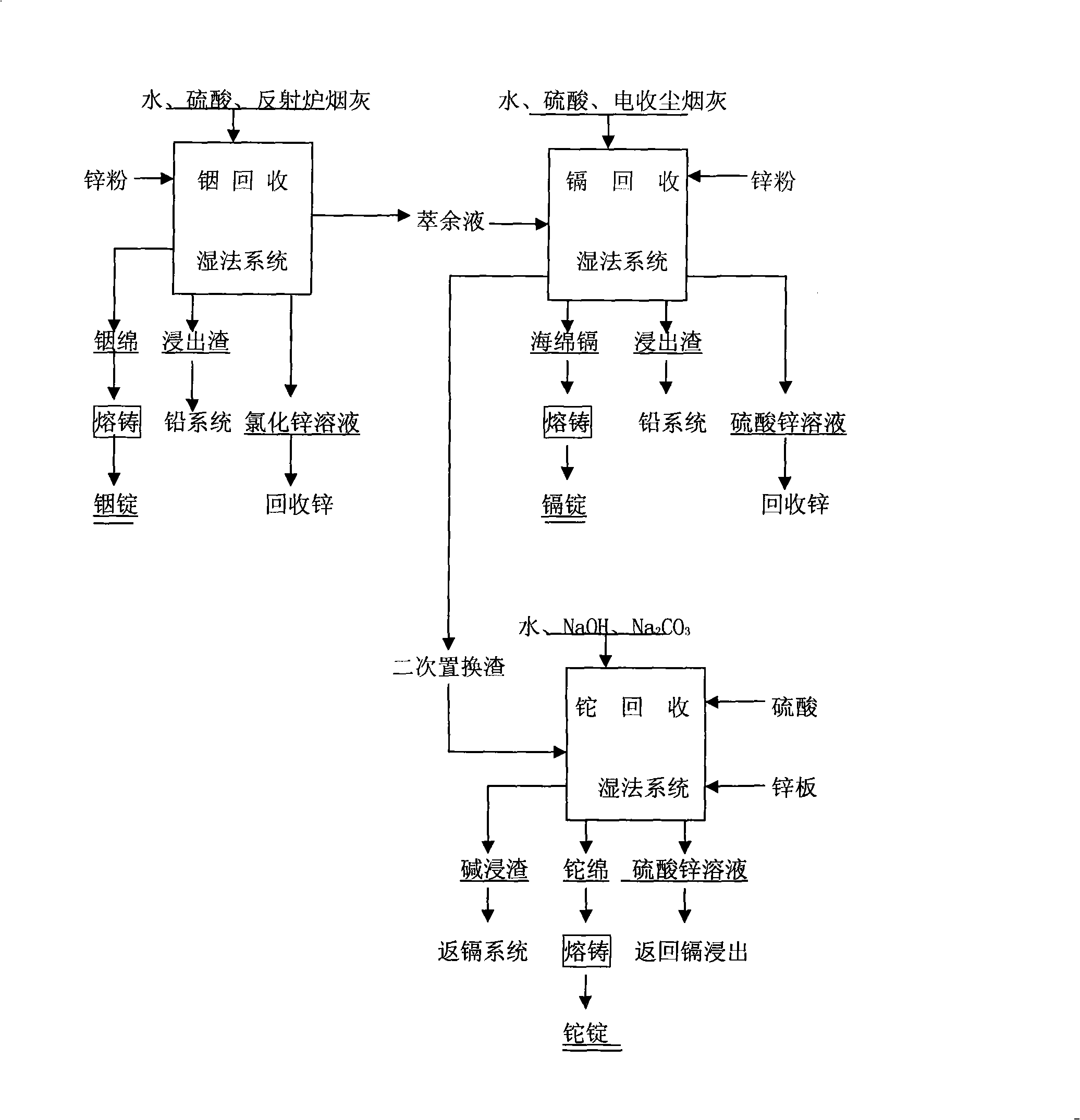

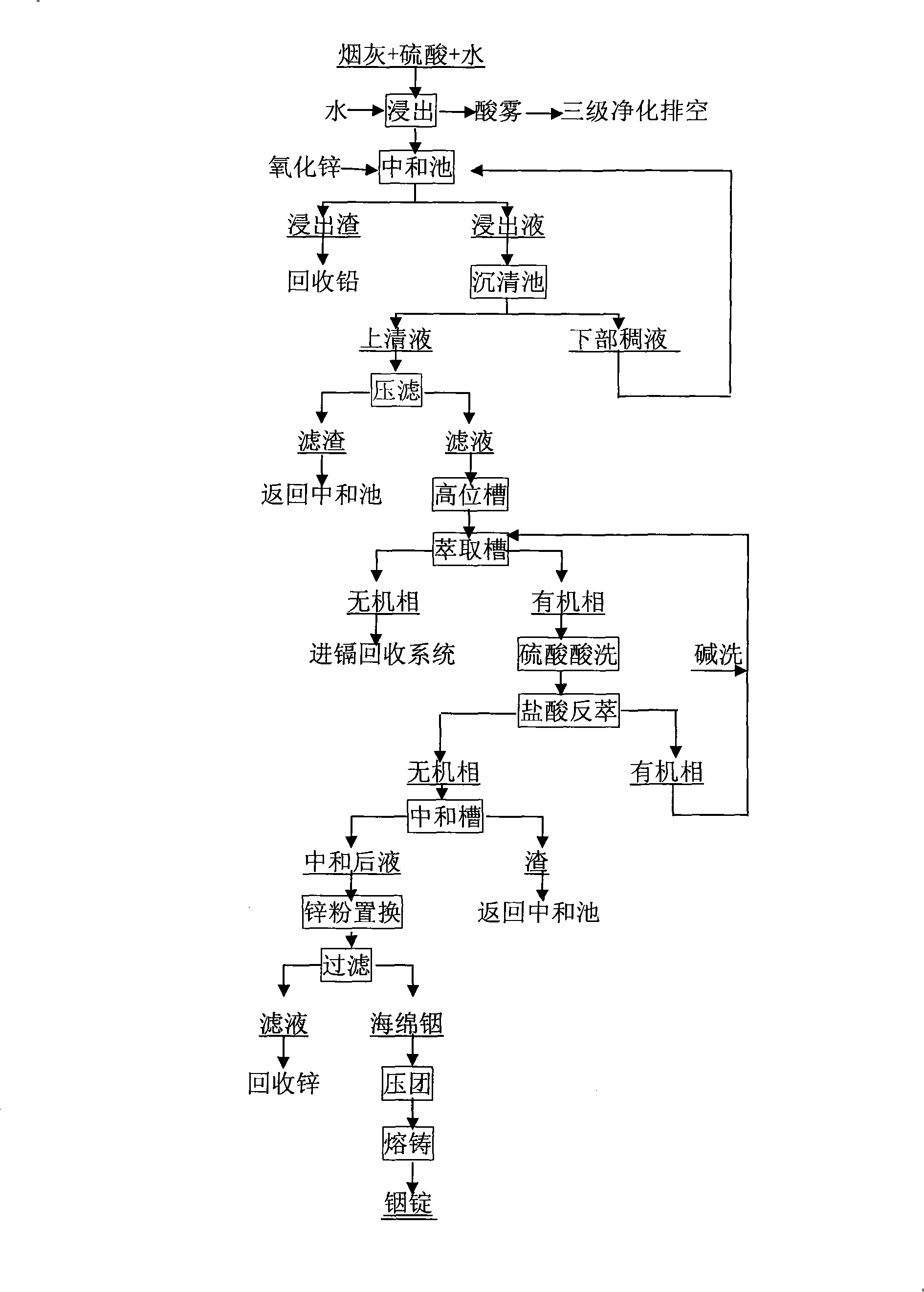

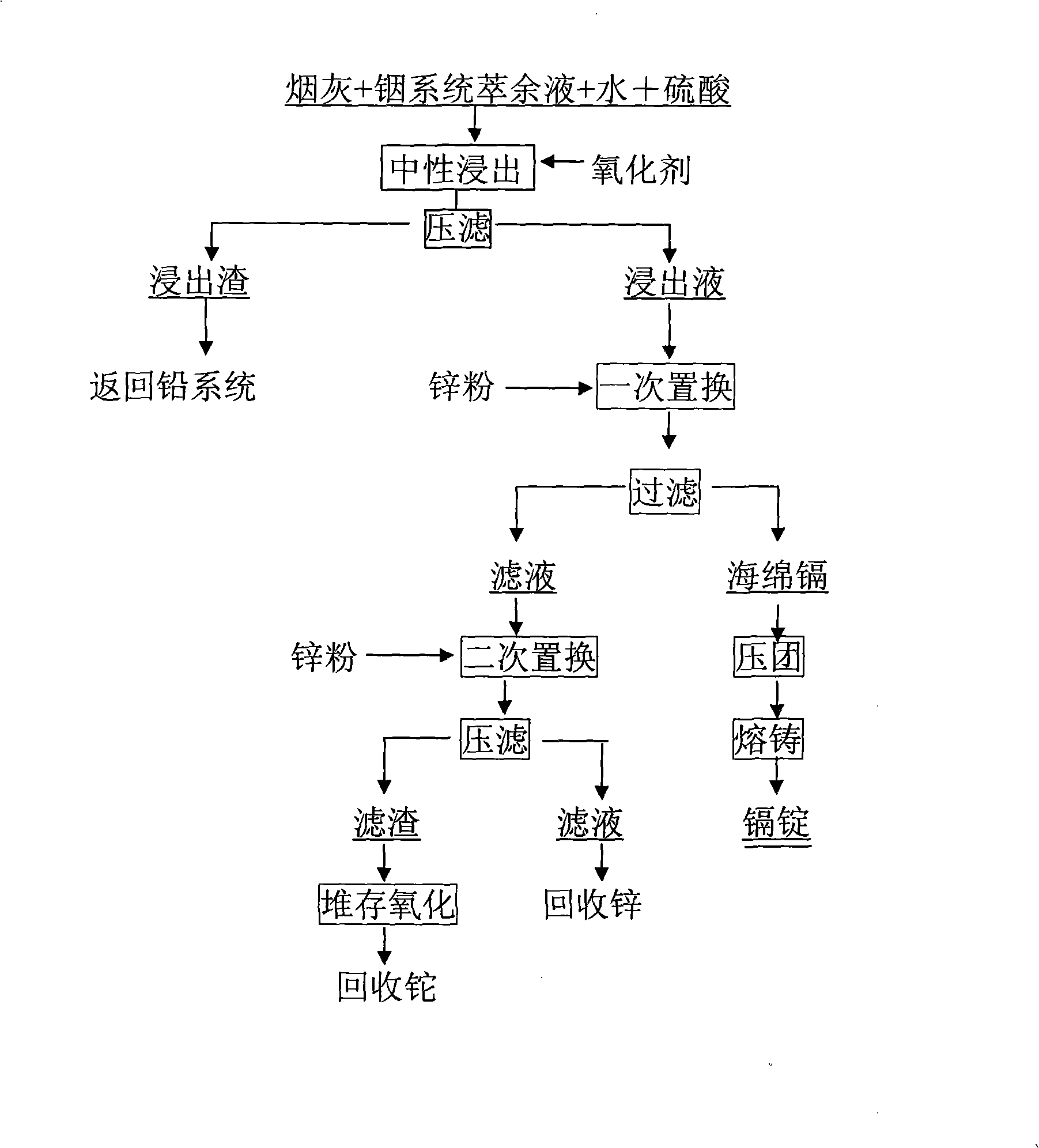

Method used

Image

Examples

Embodiment

[0036]Example: 1 ton of reverberatory furnace (containing 1.4 kg of indium) soot is leached by adding water and sulfuric acid, the liquid-solid ratio is 2:1, the temperature is about 90°C, the time is 4 hours, the initial acidity is 300-350g / l, the reaction is completed and diluted with water When the final acid is 70-80g / l, add zinc oxide to the neutralization pool to adjust the final acid content to 10-20g / l, and press filter. The output leaching residue is about 0.8 tons, and the leaching liquid is 4m 3 about. The leaching solution enters the settling tank to settle, and then enters the extraction process through the high level tank. The organic phase used for extraction is P 204 Add sulfonated kerosene, P in the organic phase 204 20-35%, sulfonated kerosene 65-80%, the volume ratio of the organic phase and the inorganic phase during the extraction process is 3:7, the extraction temperature is normal temperature, the number of stages: 5, and the mixing time is 12 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com