Method for increasing aluminum-containing complex compound hydrogen-storing material circulation stability

A technology of cycle stability and hydrogen storage materials, applied in the production of hydrogen, etc., can solve the problems of hindering the potential performance of materials, the reduction of effective hydrogen storage capacity, and the agglomeration of particles, and achieve the effect of low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

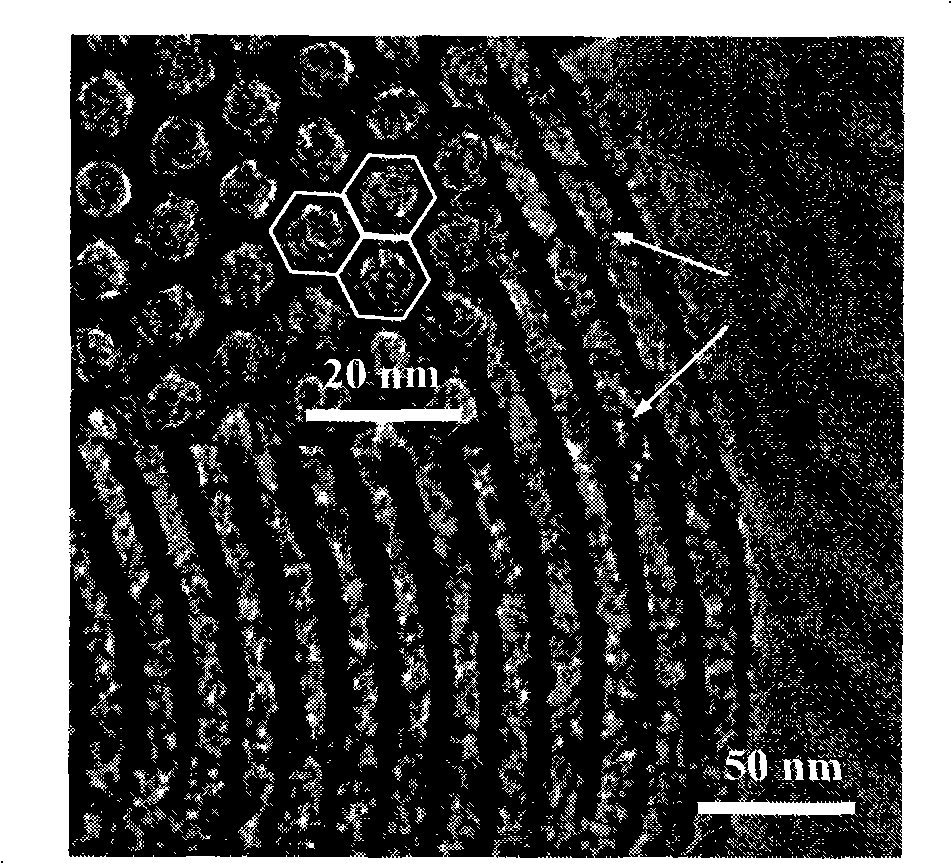

[0028] Preparation of nano-sized NaAlH with good cycle stability 4 ,Specific steps are as follows:

[0029] (1) Equipped with NaAlH 4 the solution

[0030] At room temperature and under the protective atmosphere of inert gas nitrogen or argon, accurately weigh 1 gram of aluminum-containing nano-complex hydride NaAlH 4 powder and 99 g THF, then NaAlH 4 Add the powder into tetrahydrofuran, stir well until it is completely dissolved, and obtain NaAlH with a mass content of 1%. 4 solution.

[0031] (2) NaAlH 4 Solution dropwise infiltration into mesoporous SiO 2

[0032] With the NaAlH obtained by step (1) 4 The solution was added dropwise to mesoporous SiO with a pore diameter of 5-10 nm 2 Powder, infiltrate at 40-50°C for 1-2 hours, add solution 3-6 times and keep warm to make NaAlH 4 into the tunnel.

[0033] (3) will be permeated with NaAlH multiple times 4 The sample was dried under vacuum for 24-48 hours to obtain nano-sized NaAlH filled in the pores of the porou...

Embodiment 2

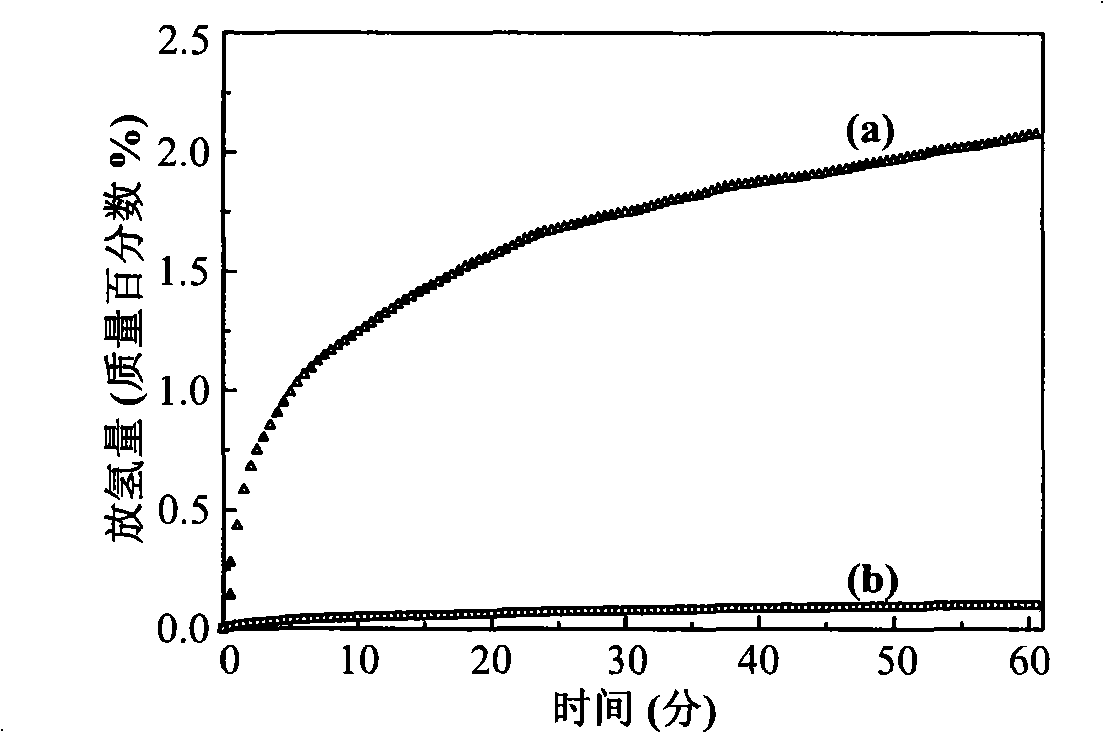

[0039] NaAlH 4 For example, figure 2 The curves of dehydrogenation amount and dehydrogenation time were compared at the same temperature of 150°C for 1 hour. It can be seen from the figure that, under the condition of lower dehydrogenation temperature without adding any catalyst, the usual NaAlH 4 The sample hardly releases hydrogen, while the prepared mesoporous SiO 2 Nanosized NaAlH in matrix pores 4 There was 2.0 wt% hydrogen evolution.

Embodiment 3

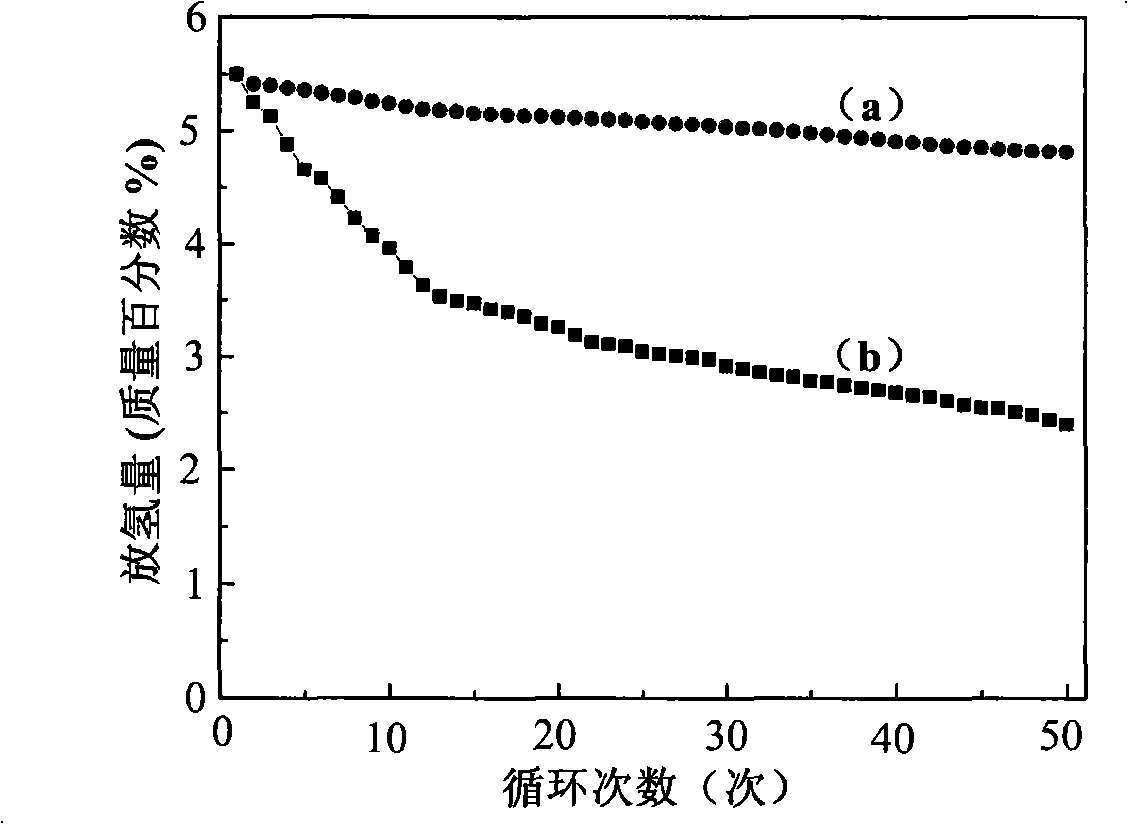

[0041] NaAlH 4 For example, image 3 Comparing the hydrogen absorption and desorption cycle under the same conditions, the curves of the amount of hydrogen released by the sample and the number of cycles, it can be seen from the figure that, without adding any catalyst, the prepared mesoporous SiO 2 Nanosized NaAlH in matrix pores 4 , has very good cycle stability, in which after 50 hydrogen absorption and desorption cycles, the hydrogen desorption capacity remains at 90% of the theoretical capacity, while the conventional NaAlH 4 Only about 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com