Thermoplastic polyolefin-like waterproof material and preparation method thereof

A thermoplastic polyolefin and waterproof material technology, applied in the direction of building insulation materials, chemical instruments and methods, and other chemical processes, can solve the problems of low tensile strength, poor aging performance, environmental pollution, etc., and achieve high tensile strength, Good puncture resistance and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

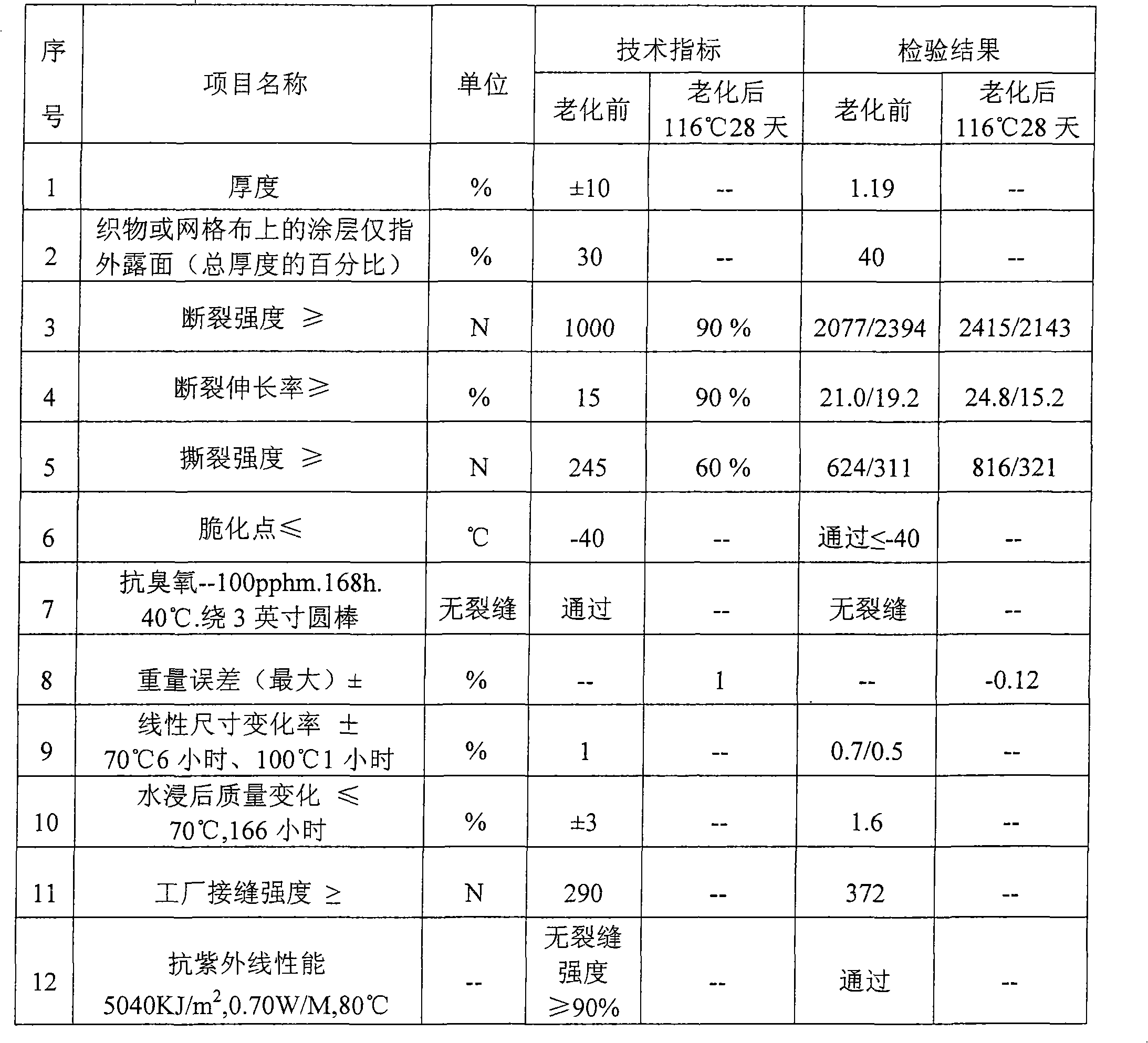

Embodiment 1

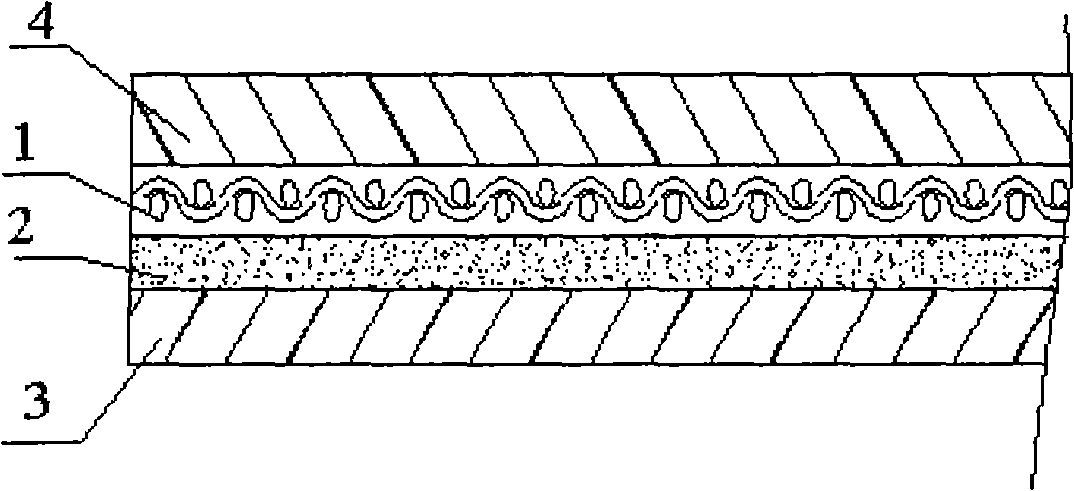

[0033] preparation figure 1 The thermoplastic polyolefin waterproof material shown.

[0034] Use warp knitted polyester fabric as the base fabric, with a total thickness of 2.0mm;

[0035] The fineness of the warp yarn of the base fabric is 1000D, the fineness of the weft yarn is 1000D, and the organization density is: 9 warps / cm, 9 wefts / cm

[0036] The bottom material is a dark layer, the thickness is 40% of the total thickness of the waterproof material, the thickness of the performance improvement layer is 20% of the total thickness of the waterproof material, and the surface layer is 30% of the total thickness;

[0037] Components and parts by weight of each layer:

[0038] Surface layer

Modified layer

Bottom layer

TPO

100

100

100

Polymer modified materials

5

25

15

Filling modifier

5

40

10

0.2

0.4

0.2

Antioxidants

1

0

...

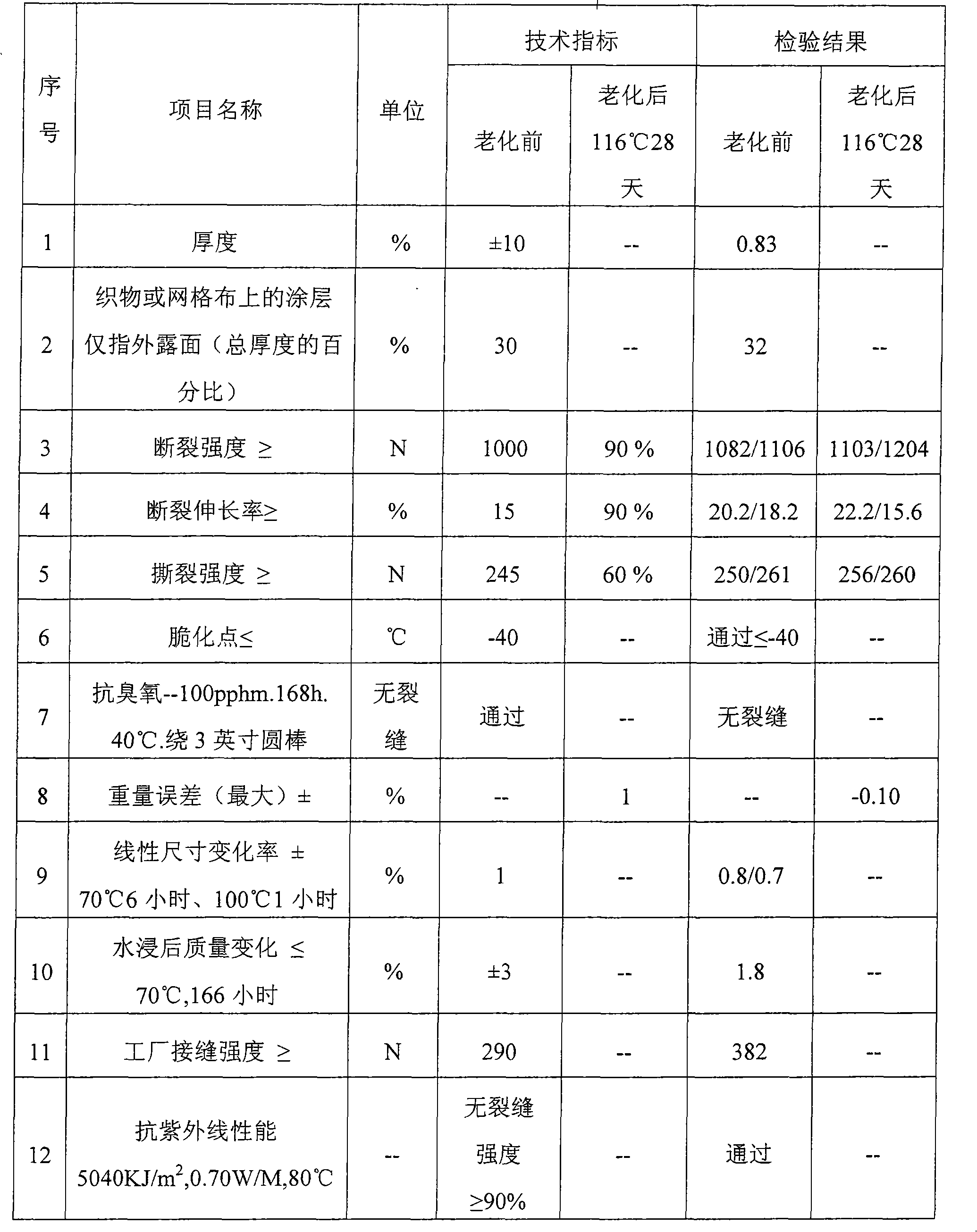

Embodiment 2

[0054] preparation figure 1 The thermoplastic polyolefin waterproof material shown.

[0055] Use warp knitted polyester fabric as the base fabric, with a total thickness of 0.8mm;

[0056] The warp yarn fineness of the base fabric is 250D, the weft yarn fineness is 250D, and the organization density is: 6 warps / cm and 6 wefts / cm; the bottom material is a dark layer with a thickness of 20% of the total thickness of the waterproof material. The thickness of the performance improvement layer is 40% of the total thickness of the waterproof material, and the surface layer is 40% of the total thickness;

[0057] Components and parts by weight of each layer:

[0058] Surface layer

Modified layer

Bottom layer

TPO

100

100

100

Polymer modified materials

15

15

25

Filling modifier

20

20

30

0.3

0.6

0.3

Antioxidants

2

0

0.5

Colorant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com