Boron-chromium-rare-earth co-seeping agent and its low-temperature co-seeping process below eutectoid line

A technology of co-infiltration agent and rare earth, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of high brittleness, unsuitability for precision parts application, large deformation, etc., and achieve small brittleness and small deformation , to reduce the effect of segregation on grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: A boron-chromium-rare earth co-penetration agent, including the following components by weight, 6.1 parts of high-carbon ferrochromium, 5 parts of rare earth chloride, 15.5 parts of sodium fluorosilicate, 11 parts of silicon-calcium alloy, 23 parts of borax 35 parts of graphite, 1.8 parts of urea, and 1 part of ammonium chloride.

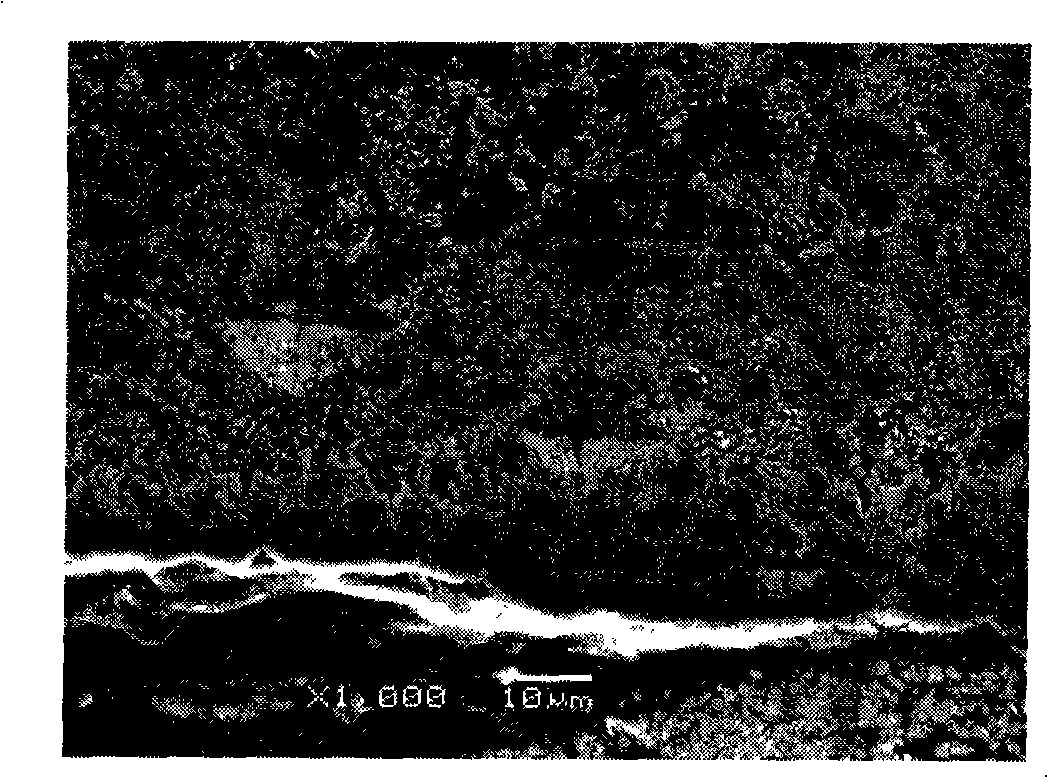

[0031] No. 20 steel sample was shot peened for 1 hour, and then boron-chromium-rare earth co-infiltration was carried out under the condition of 680°C×4h, and the sample was observed and tested after infiltration. The process is as follows:

[0032] 1. Shot blasting the workpiece

[0033] A Q3110A shot blasting machine is used, and the shot blasting time is 60 minutes. The steel shots are cast steel balls with a diameter of 1.4mm, and the linear velocity of the steel balls is 70m / s.

[0034] 2. Co-infiltration agent preparation

[0035] Copenetration agent is through L 18 (6 1 ×3 6 ) L 8 (4 1 ×2 4 ) pan-selected and sel...

Embodiment 2

[0043] Embodiment 2: A kind of boron-chromium-rare earth co-infiltration agent, comprises the composition of following weight ratio, high-carbon ferrochrome 6.2 parts, rare earth chloride 6 parts, sodium fluorosilicate 16 parts, silicon-calcium alloy 11.5 parts, borax 23.5 parts 35.5 parts of graphite, 2 parts of urea, and 1.05 parts of ammonium chloride.

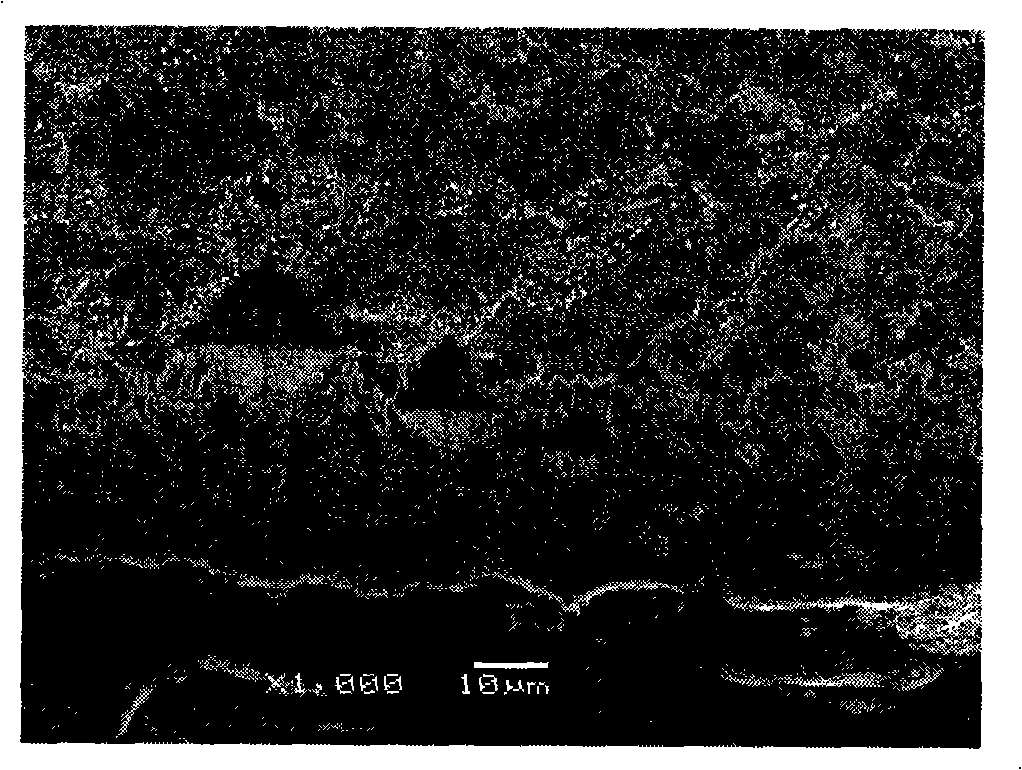

[0044] Shot peen No. 20 steel sample for 1.5 hours, and then carry out boron-chromium-rare earth co-infiltration under the condition of 680℃×4h. The process is as follows:

[0045] 1. Shot blasting the workpiece

[0046] The Q3110A shot blasting machine is adopted, and the shot blasting time is 90 minutes. The steel shots are cast steel balls with a diameter of 1.4mm, and the linear speed of the steel balls is 50m / s;

[0047] 2. Co-infiltration agent preparation

[0048] Copenetration agent is through L 18 (6 1 ×3 6 ) L 8 (4 1 ×2 4 ) pan-selected and selected powdery boron-chromium-rare earth co-penetration agent, i...

Embodiment 3

[0057] Embodiment 3: A boron-chromium-rare earth co-penetration agent, including the following components by weight ratio, 6.15 parts of high-carbon ferrochromium, 5.5 parts of rare earth chloride, 15.7 parts of sodium fluorosilicate, 11.3 parts of silicon-calcium alloy, 23.2 parts of borax 35.3 parts of graphite, 1.9 parts of urea, and 1.02 parts of ammonium chloride.

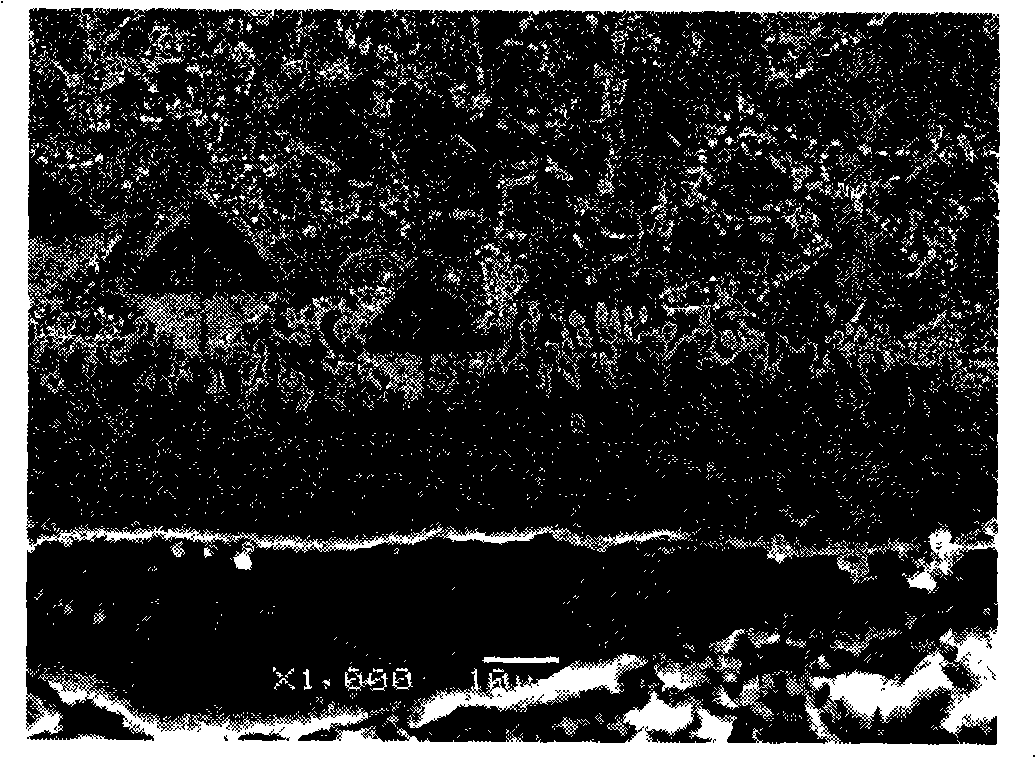

[0058] Shot peen No. 45 steel sample for 1 hour, carry out co-infiltration of boron-chromium-rare earth under the condition of 680℃×4h, observe and test the sample after infiltration. The process is as follows:

[0059] 1. Shot blasting the workpiece

[0060] The Q3110A shot blasting machine is adopted, and the shot blasting time is 60 minutes. The steel shots are cast steel balls with a diameter of 1.4mm, and the linear speed of the steel balls is 70m / s;

[0061] 2. Co-infiltration agent preparation

[0062] Copenetration agent is through L 18 (6 1 ×3 6 ) L 8 (4 1 ×2 4 ) pan-selected and selected pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com