Purification method for wastewater of ammunition disassembly

A wastewater purification and ammunition technology, which is applied in the field of water purification, can solve the problems of intermittent discharge, ammunition dismantling wastewater purification method is immature, and the water volume is small, so as to achieve high treatment efficiency, complete and thorough ultraviolet ozone oxidation process, and short residence time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

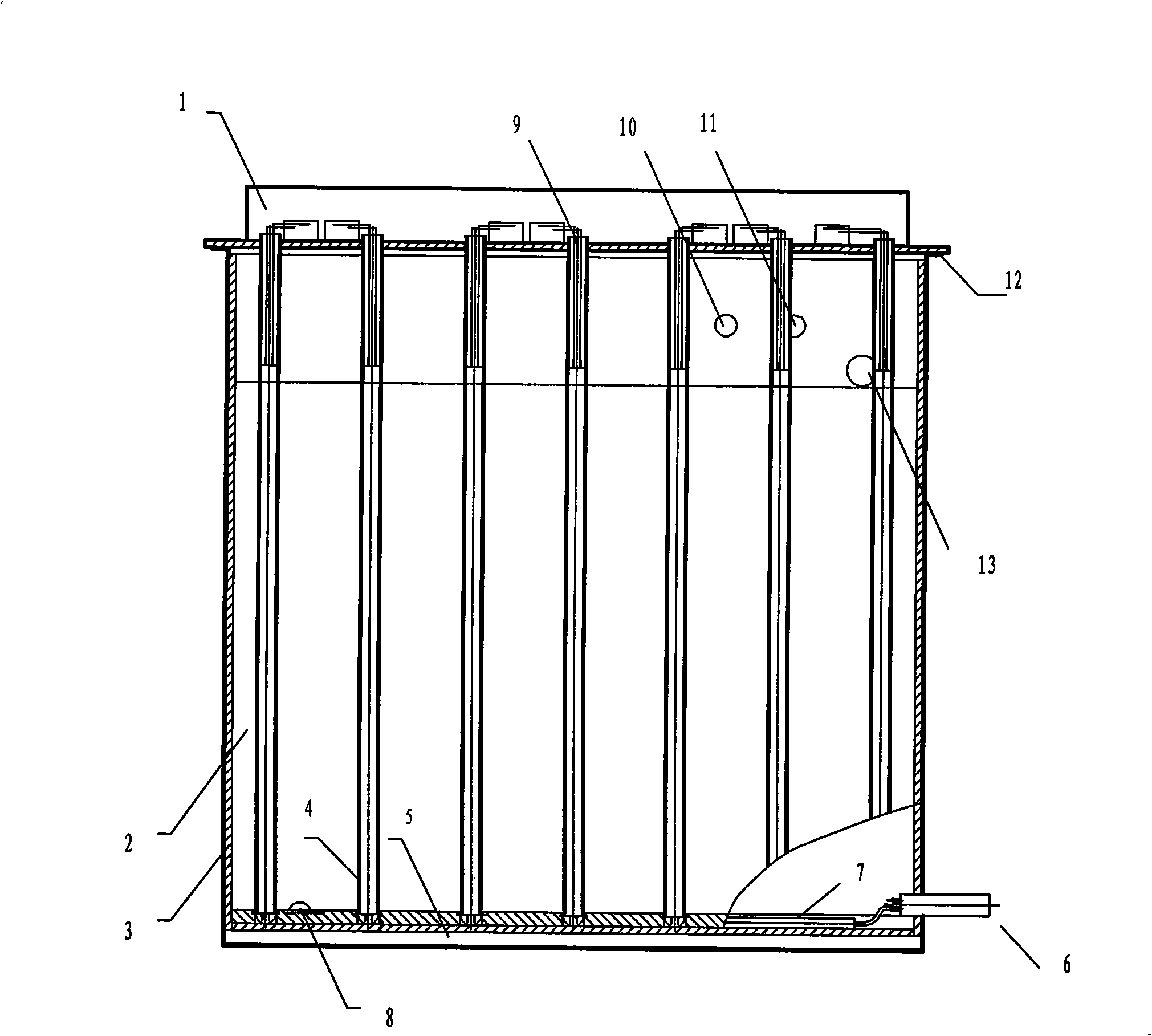

[0030] A certain ammunition destruction station concentrates on destroying waste ammunition. The concentrated working time is about two weeks every year, and 20m of ammunition dismantling wastewater is generated. 3 , into the sump. The size of the existing sump is 3.3m×3.3m×3m, which can meet the requirements.

[0031] The sump is located underground, covered with a cement prefabricated board, and ancillary rooms are built above the sump to protect the processing equipment and eliminate the noise caused by the air compressor.

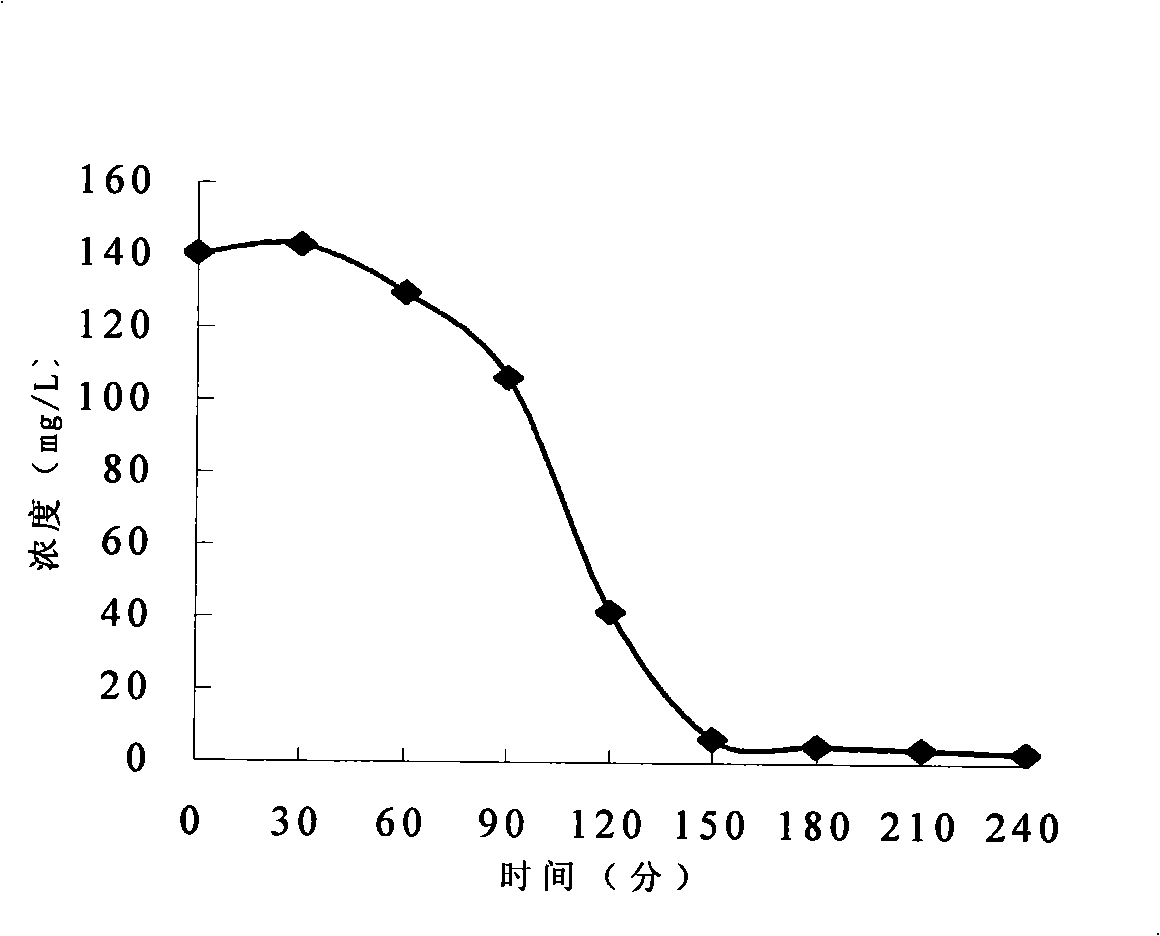

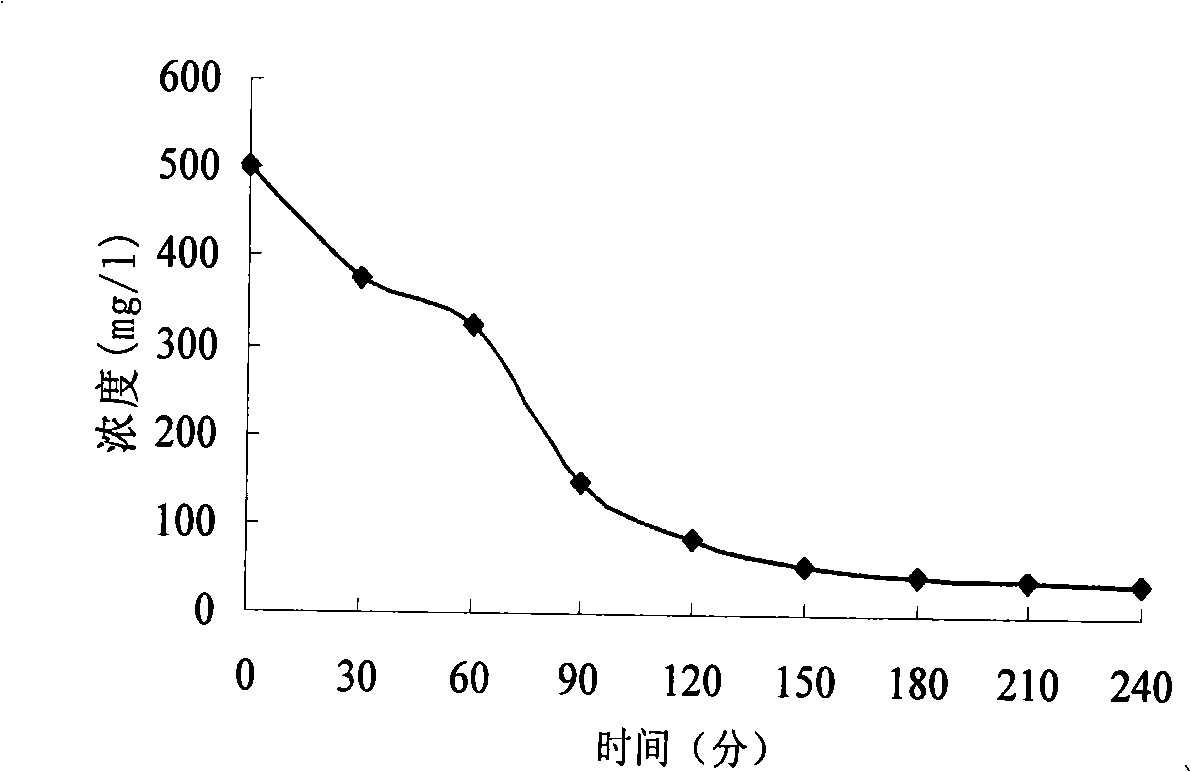

[0032] The wastewater is lifted by the pump into the air flotation filter, and most of the flocs in the wastewater are removed under the air flotation of the air flotation filter, and the SS (Suspended Solid) is reduced from 600mg / l of raw water to 100mg / l; The air flotation device has no degradation effect on COD (chemical oxygen demand), but due to the reduction of organic matter in suspended matter, the COD of raw water is reduced from 800mg / l to 600...

Embodiment 2

[0043] It is basically the same as Embodiment 1, the difference is:

[0044] Activated carbon filter material, particle size d min 2mm, filter layer thickness 0.5m.

Embodiment 3

[0046] It is basically the same as Embodiment 1, the difference is:

[0047] Activated carbon filter material, particle size d min 4mm, filter layer thickness 1.5m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com