Hypergravity auxiliary non-equilibrium preparation method for aluminum oxide base transparent ceramic material

A technology based on transparent ceramics and alumina, which is applied in the field of preparation of oxide transparent ceramics. It can solve the problems of expensive material raw materials and sintering costs, high cost, and long preparation cycle, so as to promote preferred orientation, high production efficiency, and short preparation cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

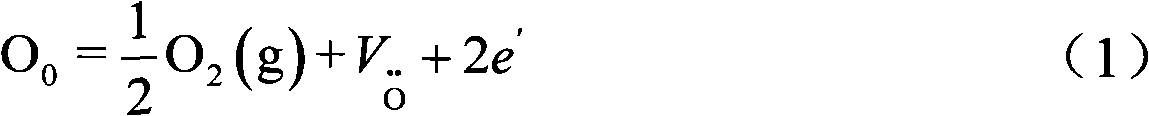

Embodiment 1

[0034] Get ultrafine aluminum powder (particle size is 20 microns, purity greater than 98%) by weight to be 23.9 parts, analytically pure Fe 2 o 3 Powder is 71.1 parts, analytically pure CaF 2 The powder is 5 parts, and a total of 300 grams of raw materials are weighed, with absolute ethanol as the medium, put into a clean ball mill jar, fix the ball mill jar on the planetary ball mill, adjust the speed of the planetary ball mill at 300 rpm, and the mixing time For 100 minutes, dry the mixed powder material and compact it into a green body material with a diameter of 80 mm and a relative density of 60%; put the obtained green body material into a reaction vessel, and open the supergravity combustion synthesis device to react chamber, fix the reaction vessel in the supergravity combustion synthesis device and then close the reaction chamber; start the vacuum pump of the supergravity combustion synthesis device, evacuate until the vacuum degree in the reaction chamber is 100 Pa...

Embodiment 2

[0036] Get 31.5 parts of superfine aluminum powder (particle size is 50 microns, purity greater than 98%) by weight, analytically pure CrO 3 58.5 parts of powder, 10 parts of analytically pure MgO powder, weigh 200 grams of raw materials in total, use absolute ethanol as the medium, put them into a clean ball mill jar, fix the ball mill jar on the planetary ball mill, and adjust the speed of the planetary ball mill at 300 revolutions per minute, the mixing time is 100 minutes, the mixed powder material is dried and pressed into a green body material with a diameter of 80 mm and a relative density of 60%. Put the obtained green body material into the reaction vessel, open the reaction chamber of the supergravity combustion synthesis device, fix the reaction vessel in the hypergravity combustion synthesis device and close the reaction chamber; start the vacuum pump of the supergravity combustion synthesis device, and evacuate to the reaction chamber The internal vacuum is 1000 P...

Embodiment 3

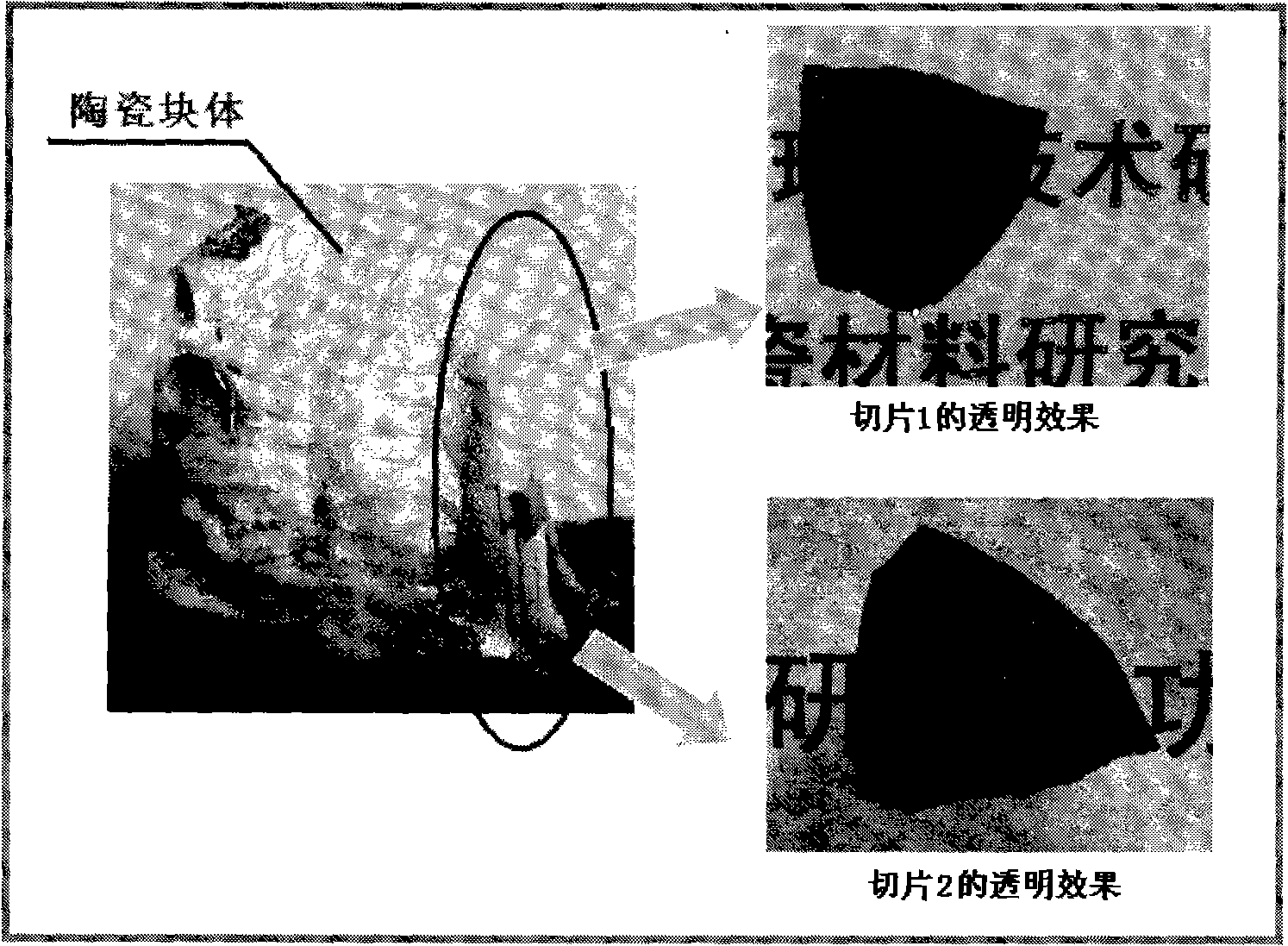

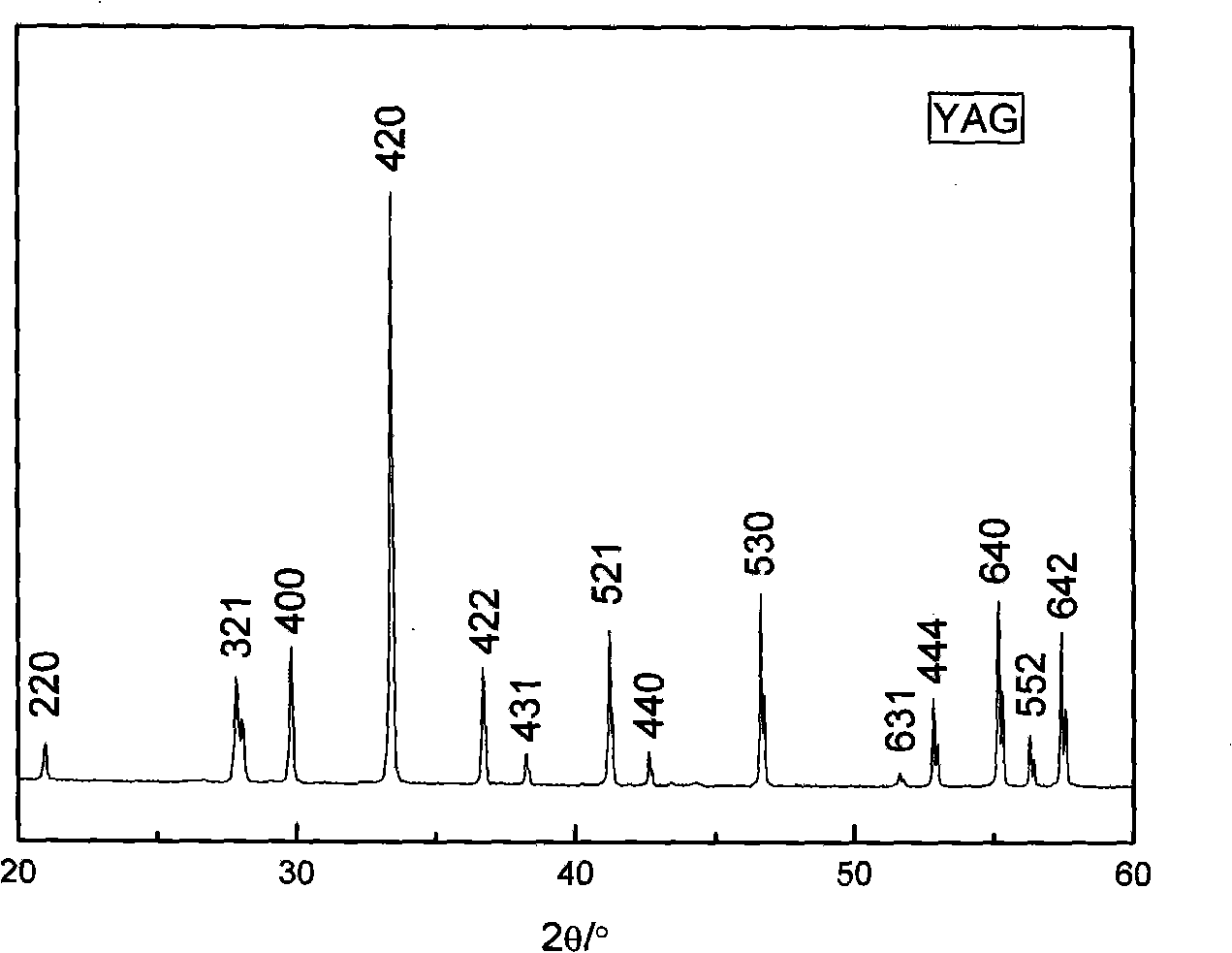

[0038] Take 13.2 parts of ultrafine aluminum powder (particle size is 80 microns, purity greater than 98%), 53.8 parts of analytical pure NiO powder, analytical pure Y 2 o 3 33.0 parts of powder, weigh 300 grams of raw materials in total, put them into a clean ball mill jar, use absolute ethanol as the medium, adjust the speed of the planetary ball mill at 300 rpm, and mix for 100 minutes, and dry the mixed raw materials After dry treatment, press it into a green body material with a diameter of 80 mm and a relative density of 55%. The obtained green body material is put into a reaction vessel, and the reaction chamber of the high-gravity combustion synthesis device is opened, and the reaction vessel is fixed on the high-gravity combustion synthesis device and then closed. Reaction chamber; start the vacuum pump of the supergravity combustion synthesis device, evacuate until the vacuum degree in the reaction chamber is 10 Pascals, close the vacuum pump of the supergravity comb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com