Method for separating biological medicine fertilizer effective component from biogas fluid

A biomedical fertilizer and active ingredient technology, applied in the field of chemical engineering, can solve the problems of loss of active ingredients, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

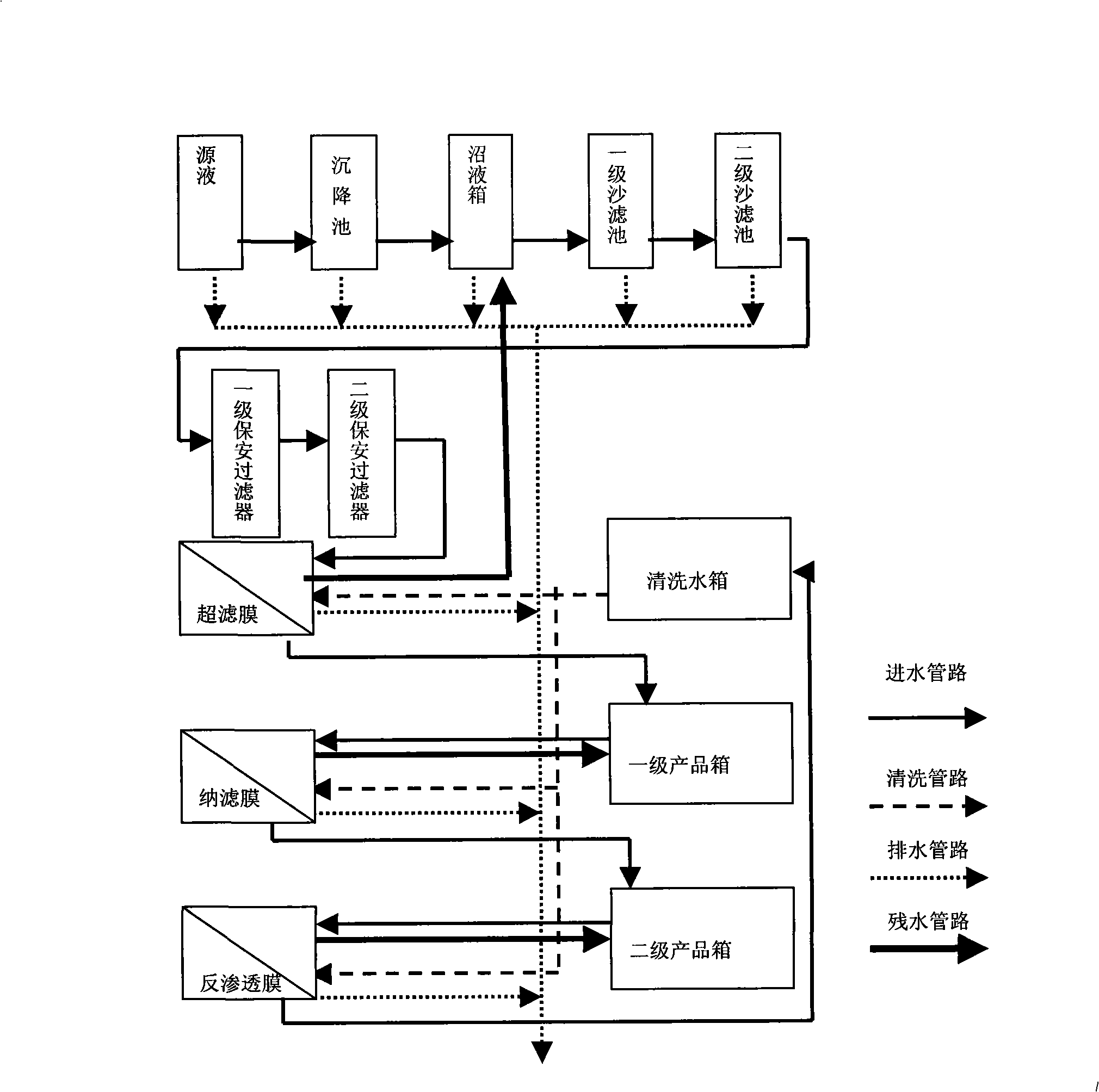

[0013] Below in conjunction with the accompanying drawings of the description, the technical method for separating the active ingredients of biomedicine fertilizer from the biogas slurry by the membrane separation technology of the present invention is described in detail, as shown in the accompanying drawings of the description:

[0014] Pretreatment first, including sedimentation, sand filtration, security filtration, and ultrafiltration, aims to remove large particles with a molecular weight above 100,000, microorganisms, and reduce conductivity. After the biogas slurry in the biogas digester is settled to remove larger suspended solids, it enters the biogas slurry tank for storage, and the biogas slurry in the biogas slurry tank enters the primary sand filter tank (filled with activated carbon and quartz sand) through the feed pump. The secondary sand filter (filler is quartz sand), and then enters the ultrafiltration membrane separator for filtration after two-stage securi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com