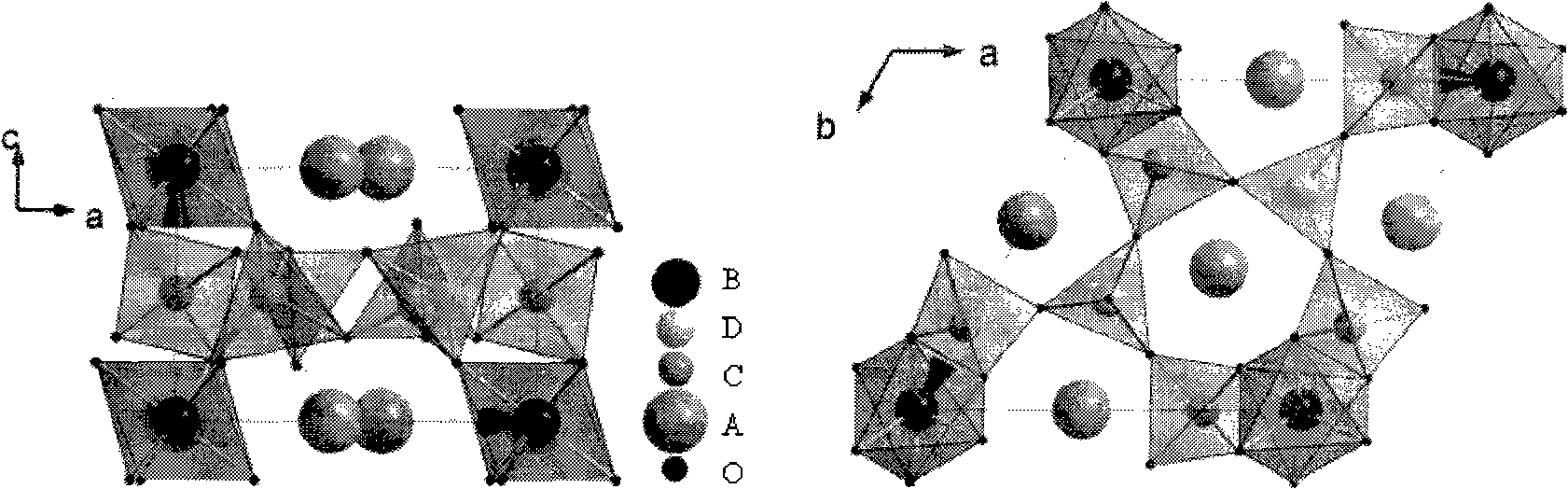

Piezo crystal having four-lattice structure

A piezoelectric crystal and lattice technology, applied in the field of four-lattice structure piezoelectric crystals, can solve problems such as poor frequency and temperature stability, high electromechanical coupling coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

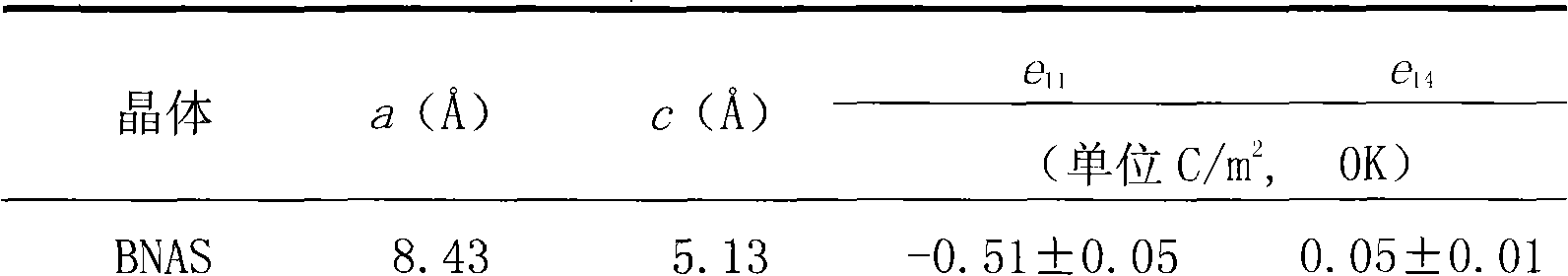

Examples

Embodiment 1

[0020] Growth of BNAS crystals by pulling method:

[0021] Raw material BaCO with a purity of 99.99% 3 , Nb 2 o 5 、Al 2 o 3 , SiO 2 Ingredients according to the following formula:

[0022] 6BaCO 3 +Nb 2 o 5 +3Al 2 o 3 +4SiO 2 = 2Ba 3 NbAl 3 Si 2 o 14 +6CO 2

[0023] Mix the raw materials thoroughly and briquette, then sinter at 1150°C for 24 hours to obtain Ba 3 NbAl 3 Si 2 o 14 polycrystalline material.

[0024] Adopt intermediate frequency induction heating pulling furnace, use iridium gold crucible, heat up to 1520°C for 2 hours to melt the sintered material, keep the temperature for 4 hours to stabilize the melt; use a-direction seed crystal, grow at 1458°C; grow at 45° The angle is placed on a slanted shoulder, and when the diameter of the crystal reaches 10mm, it turns to grow in an isodiameter, and the growth stops when the diameter reaches 20mm, and the cooling rate is 70°C per hour. During the growth process, the rotational speed was 15 rpm, and...

Embodiment 2

[0026] Growth of BTAS crystals by pulling method:

[0027] Raw material BaCO with a purity of 99.99% 3 、 Ta 2 o 5 、Al 2 o 3 , SiO 2 Ingredients according to the following formula:

[0028] 6BaCO 3 +Ta 2 o 5 +3Al 2 o 3 +4SiO 2 = 2Ba 3 TaAl 3 Si 2 o 14 +6CO 2

[0029] Mix the raw materials thoroughly and briquette, then sinter at 1150°C for 24 hours to obtain Ba 3 TaAl 3 Si 2 o 14 polycrystalline material.

[0030] Adopt intermediate frequency induction heating pulling furnace, use iridium gold crucible, heat up to 1532°C for 2 hours to melt the sintering material, keep it for 4 hours to stabilize the melt; use a-direction seed crystal, grow at 1463°C; grow at about 40 Angle of ° puts the inclined shoulder, when the crystal diameter reaches 13mm, it turns to isodiametric growth, and when the isodiametric growth reaches 20mm, the growth stops, then the crystal is lifted from the melt, cooled to room temperature at 70°C per hour, and the crystal is taken out....

Embodiment 3

[0032] Growth of STAS crystals by pulling method:

[0033] The raw material SrCO with a purity of 99.99% 3 、 Ta 2 o 5 、Al 2 o 3 , SiO 2 Ingredients according to the following formula:

[0034] 6SrCO 3 +Ta 2 o 5 +3Al 2 o 3 +4SiO 2 =2Sr 3 TaAl 3 Si 2 o 14 +6CO 2

[0035] Mix the raw materials thoroughly and briquette, then sinter at 1150°C for 24 hours to obtain Sr 3 TaAl 3 Si 2 o 14 polycrystalline material.

[0036] Using a medium frequency induction heating pull furnace, the sintered material is placed in an iridium crucible, with N 2 As a protective atmosphere, heat up to 1540°C for 2 hours to completely melt the sintered material, and keep the temperature for 4 hours to stabilize the melt; use a-direction seed crystals, and grow them at 1460°C; put the inclined shoulder at an angle of about 40°, and crystal When the diameter reaches 12mm, turn to isodiametric growth, and stop growing when the isodiametric growth reaches 20mm, then lift the crystal out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com