Preparation for silk with quantum dot nano-particles

A technology of nanoparticles and quantum dots, applied in the field of preparation of fluorescent silk, can solve the problems of high cost, low efficiency and fast photobleaching rate of fluorescent silk, and achieve the effect of good repeatability and low cost of product properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

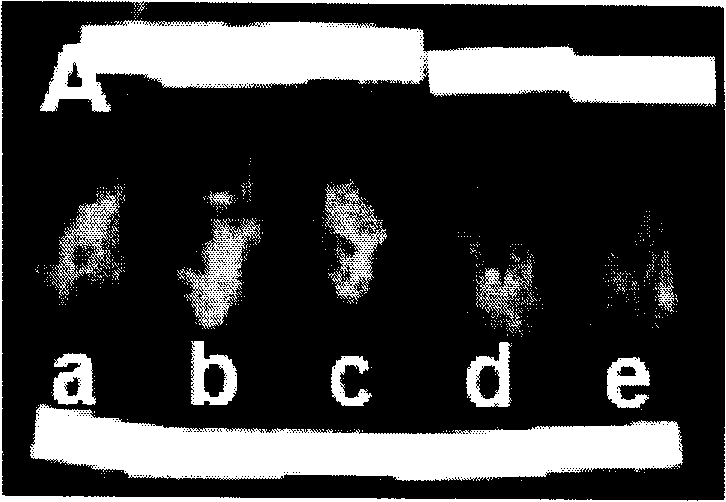

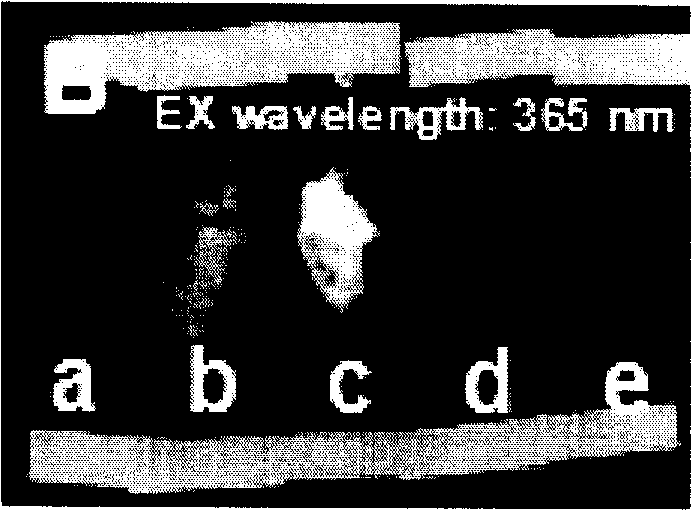

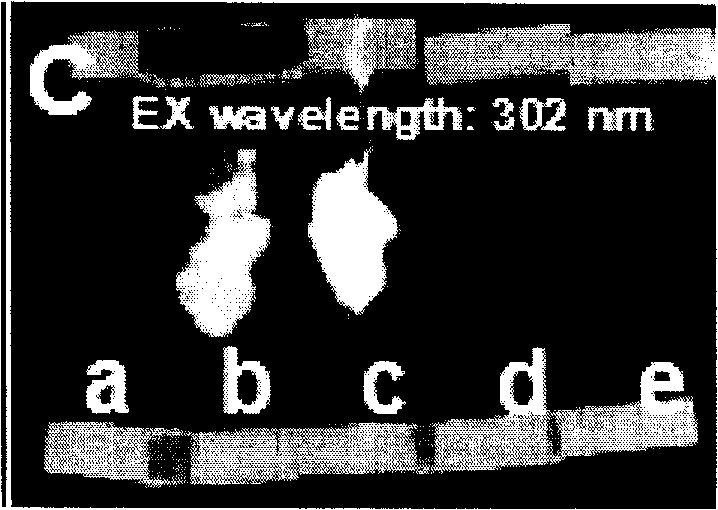

Image

Examples

Embodiment 1

[0031] Soak silkworm cocoons in 90°C NaHCO containing 0.6 wt% 3 In hot water solution to remove sericin and impurities on the surface of silk, weigh 30-35mg of dried degummed silk, soak in 5ml containing about 0.8mg·ml -1 In the polydimethyldiallyl ammonium chloride aqueous solution, the negatively charged silk will absorb the positively charged polydimethyldiallyl ammonium chloride, take out the silk after about 30min, wash it with water for several times, and then remove the silk Soak in 5ml of surface-modified small molecule mercaptopropionic acid quantum dot aqueous solution, the negatively charged quantum dots will be adsorbed to the positively charged polydimethyldiallylammonium chloride on the silk surface, after about 1 hour, take out the silk and Wash several times with water, and then soak in polydimethyldiallyl ammonium chloride aqueous solution, so repeatedly alternately soak in polydimethyldiallyl ammonium chloride aqueous solution and quantum dot aqueous solution...

Embodiment 2

[0036] Dihydrolipoic acid (DHLA) reacts with polyethylene glycol (PEG) to obtain a thiolated polymer (DHLA-PEG), and the DHLA-PEG is coated on the red fluorescent quantum dot CdTe / CdSe through the thiol group on the polymer , to make quantum dots coated with organic polymers, by the same method as in Example 1, the quantum dots are adsorbed on silk, in this example, soaked in polydimethyldiallyl chloride for 2 times In the ammonium aqueous solution, once soaked in the quantum dots, the silk adsorbed with the quantum dots was blotted dry with filter paper, and then dried naturally in the dark, that is, the fluorescent silk coated with the quantum dots was obtained once, and the silk with strong red fluorescence was obtained. .

Embodiment 3

[0038] Cut the cocoon layer of tussah silkworm into pieces and soak in 90°C NaHCO containing 0.6wt% 3 In the hot water solution, to remove sericin and impurities on the surface of the silk, and then in the same way as in Example 1, the red fluorescent CdTe quantum dots coated with mercaptopropionic acid were adsorbed onto the silk. In this example, soak in polydimethyldiallyl ammonium chloride aqueous solution for two times, and soak in quantum dots for one time. After absorbing the quantum dots, the silk absorbs the aqueous solution with filter paper, and then dries naturally in the dark. , that is, the fluorescent silk coated with quantum dots was obtained once, and the silk with strong fluorescence was also obtained as a result.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com