Method for preparing transistor T type nano grid

A transistor and nanotechnology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as poor adhesion, difficult removal of electron beam glue, and influence on gate foot exposure and development, etc., to achieve electron beam exposure And developing conditions are relaxed, the developing time is easy to control, and the effect of developing is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

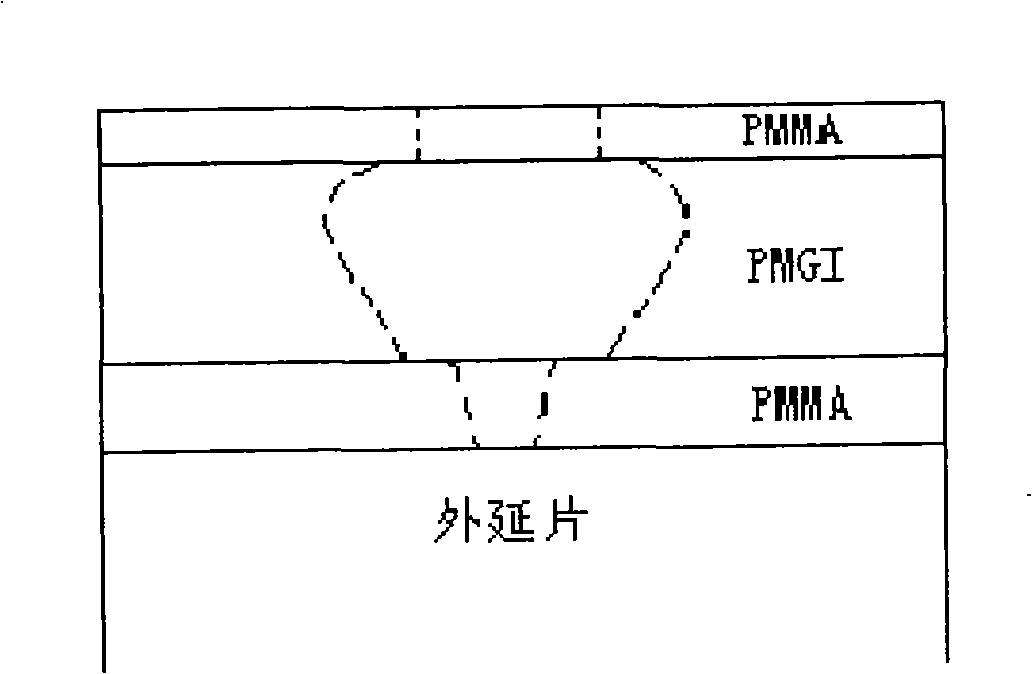

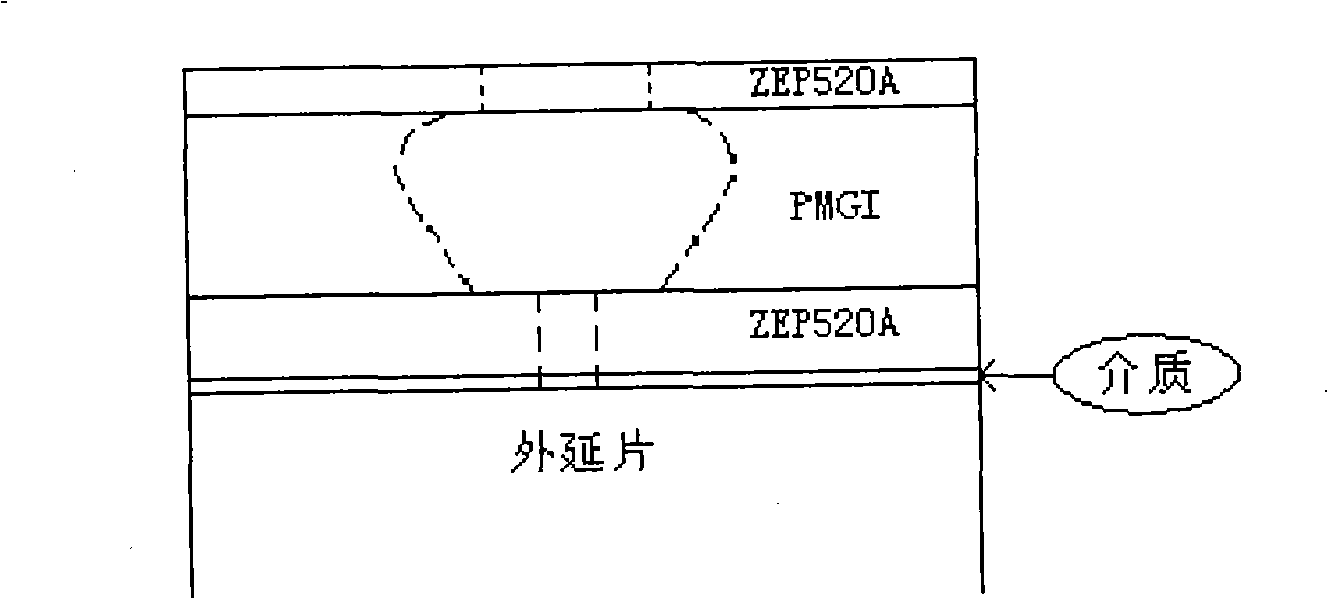

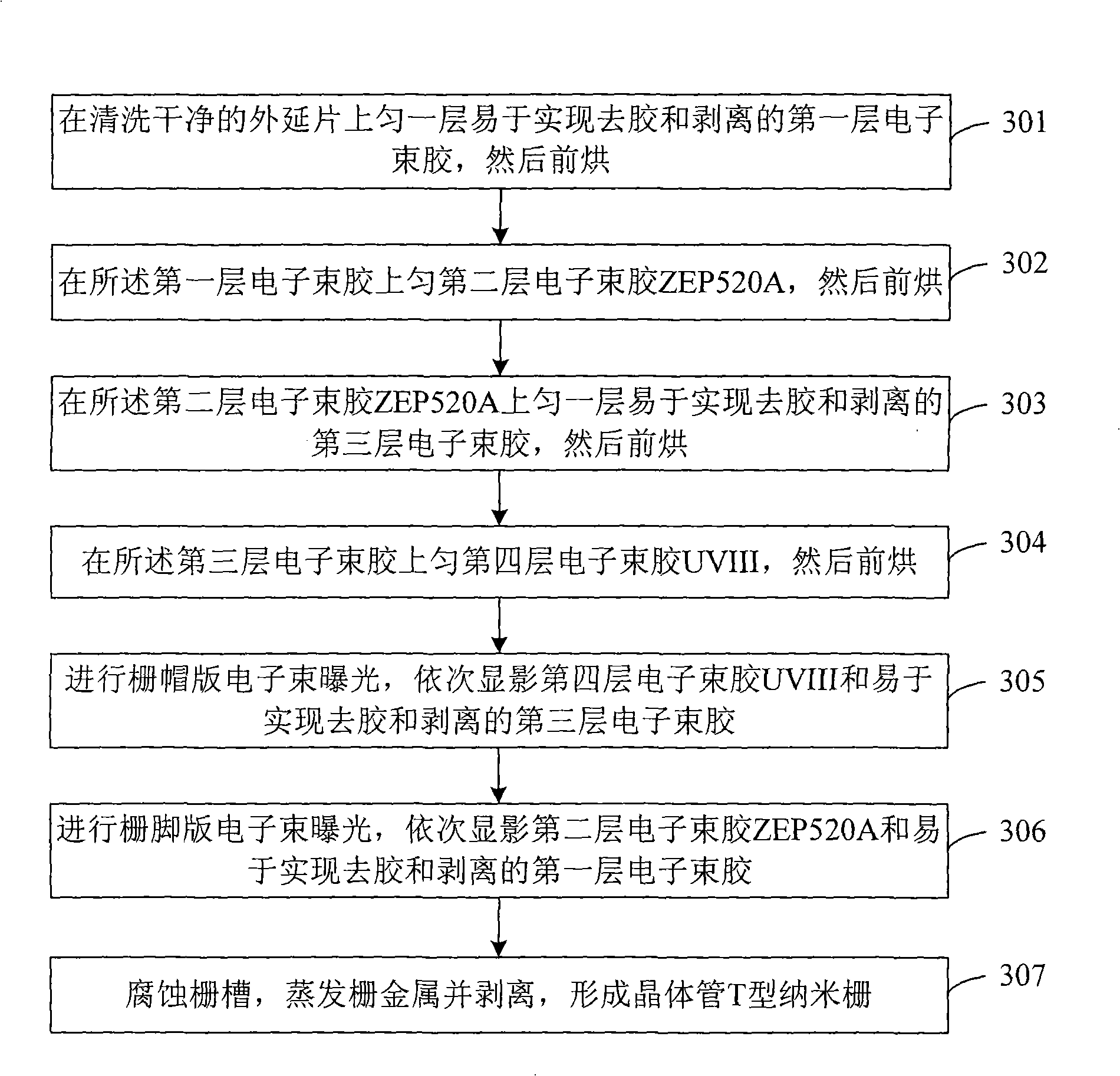

[0069] The method for fabricating the T-type nano-gate of the high electron mobility transistor (HEMT) in this embodiment is aimed at some deficiencies in the production of the T-type nano-gate of the high electron mobility transistor (HEMT) at present, and adopts four layers of PMGI / ZEP520A / PMGI / UVIII Electron beam photoresist structure (as shown in Table 1) and two electron beam exposure methods to fabricate high electron mobility transistor (HEMT) T-type nano-gate.

[0070] Table 1 is a structural representation of the PMGI / ZEP520A / PMGI / UVIII four-layer electron beam photoresist used in the method for making a high electron mobility transistor (HEMT) T-type nano-gate of the present invention:

[0071]

[0072] Table 1

[0073] In this embodiment, the first layer of electron beam glue and the third layer of electron beam glue that are easy to realize deglue and stripping are PMGI electron beam glue, which is adopted in the method for making a high electron mobility transi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com