Load type nitrogen intermingle with one-dimensional structure TiO2 and preparation method thereof

A nitrogen-doped, three-dimensional structure technology, applied in chemical instruments and methods, physical/chemical process catalysts, disinfection, etc., can solve the problems of insufficient visible light activity, short service life, and easy detachment of photocatalysts, etc., to achieve enhanced reactions The effect of mass transfer process, long service life and abundant active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

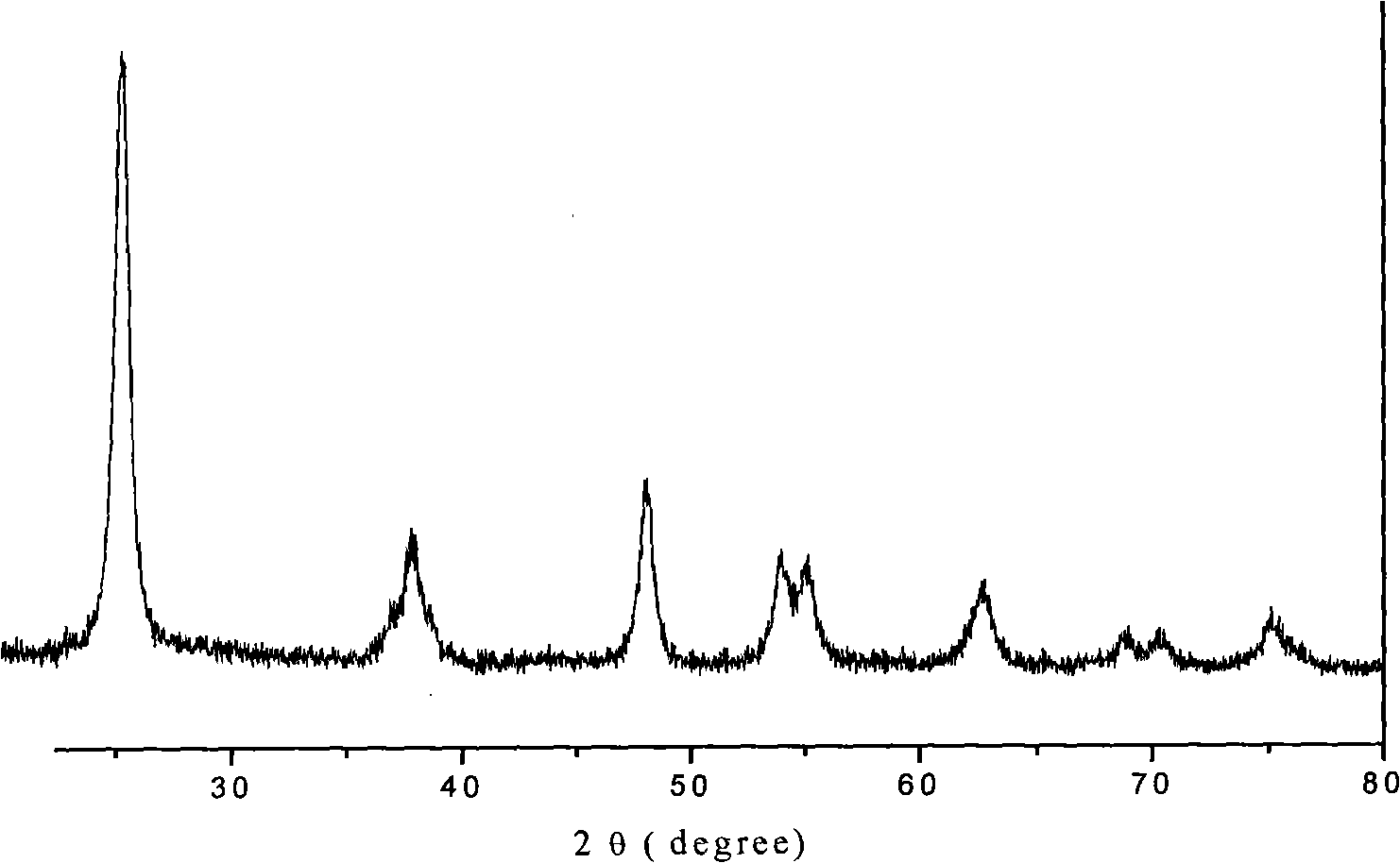

Embodiment 1

[0037] Set the area to 50cm 2 The metal Ti flakes were placed in a 10 mol / L NaOH solution and stirred continuously to obtain a mixed solution containing the metal Ti flakes. Transfer the above solution to an autoclave, keep the temperature at 150°C for 24 hours, cool, pour off the supernatant, and wash with 0.1mol / L dilute hydrochloric acid solution and deionized water to obtain flakes with a white surface. Immerse the white flakes in 0.5mol / L hydrochloric acid solution, let it stand for 24 hours, take out the flakes, and put them in a place containing NH 4 + In the solution, the solution concentration is 5mol / L, stand still for 24 hours. Take out the flakes, place them in a muffle furnace, and calcine them at 400°C for 2 hours under aerobic conditions to obtain a supported nitrogen-doped one-dimensional structure TiO 2 nanotube.

Embodiment 2

[0039] Set the area to 25cm 2 The metal Ti flakes were placed in 8 mol / L NaOH solution and stirred continuously to obtain a mixed solution containing the metal Ti flakes. Transfer the above solution to an autoclave, keep the temperature at 180°C for 12 hours, cool, pour off the supernatant, wash with 0.2mol / L dilute nitric acid solution and deionized water, and obtain a white sheet. Immerse the white flakes in 0.5mol / L nitric acid solution, let it stand for 12 hours, take out the flakes, and place them in 4 + In the solution, the solution concentration is 3mol / L, stand for 16 hours. Take out the flakes, place them in a muffle furnace, and calcinate at 500°C for 1 hour under oxygen-free conditions to obtain a supported nitrogen-doped one-dimensional structure TiO 2 Nanowires.

Embodiment 3

[0041] Set the area to 10cm 2 The metal Ti flakes were placed in a 15mol / L KOH solution and stirred continuously to obtain a mixed solution containing the metal Ti flakes. Transfer the above solution to an autoclave, keep the temperature at 160°C for 36 hours, cool, pour off the supernatant, wash with 0.5mol / L dilute sulfuric acid solution and deionized water, and obtain a white sheet. Immerse the white flakes in 0.3mol / L sulfuric acid solution, let it stand for 18 hours, take out the flakes, and put them in a place containing NH 4 + In the solution, the solution concentration is 6mol / L, stand for 8 hours. Take out the flakes, place them in a muffle furnace, and calcinate at 450°C for 3 hours under aerobic conditions to obtain a supported nitrogen-doped one-dimensional structure TiO 2 nanobelt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com