Uvioresistant polyurethane acrylic ester water coating adhesive and preparation thereof

A urethane acrylate, water-based coating technology, applied in coatings, textiles and papermaking, etc., can solve the problem of not mentioning the anti-ultraviolet function, and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

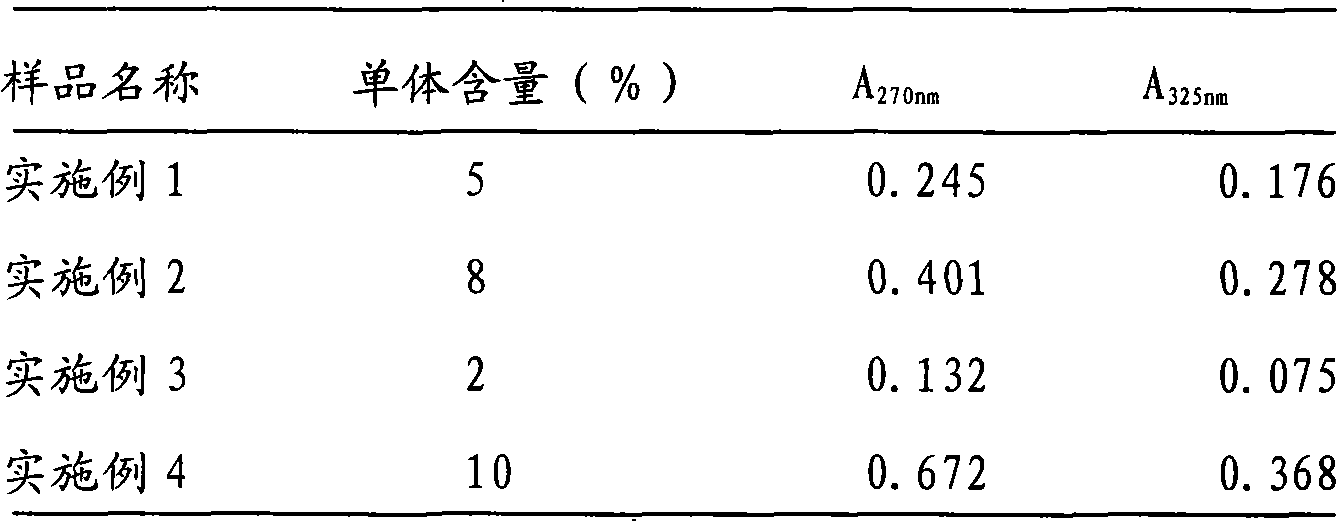

Examples

Embodiment 1

[0027] 1. Synthesize the acrylate emulsion with anti-ultraviolet function according to the emulsion polymerization method.

[0028] Preparation method: Dissolve sodium lauryl sulfate and OS-15 in deionized water, add to a four-necked flask equipped with a stirrer, reflux condenser, dropping funnel, and thermometer, and stir, then add 1 / 3 of the mass styrene, methyl methacrylate, butyl acrylate, ethyl acrylate, and 2-hydroxy-4-acrylate benzophenone were stirred and emulsified for 30 minutes, and slowly heated to 75-80°C, adding 1 / 3 mass of After reacting the initiator solution for 30 minutes and keeping it warm for 45 minutes, then at 82°C, add the remaining initiator emulsion and monomer mixture within 2-3 hours, and after keeping it warm for 30 minutes, raise the temperature to about 90°C. Heat preservation reaction for 2 hours, cool down, filter, and discharge to obtain an acrylate emulsion with a solid content of about 35% and an anti-ultraviolet function.

[0029] The raw...

Embodiment 2

[0044] 1. Synthesize the acrylate emulsion with anti-ultraviolet function according to the emulsion polymerization method.

[0045] Preparation method: with embodiment 1.

[0046] The raw material composition of emulsion is as follows:

[0047]

[0048] Monomer Type Amount (%)

[0049]

[0050] Styrene 20

[0051] Methyl methacrylate 6

[0052] Butyl acrylate 10

[0053] Isooctyl acrylate 50

[0054] 2-Hydroxy-4-acrylate benzophenone 8

[0055] Methacrylic acid 3

[0056] N-methylolacrylamide 3

[0057]

[0058] 2. Polyurethane emulsion containing double bonds was synthesized by polymerization: 127 grams of polyoxypropylene diol was added to the reaction kettle, stirred and heated to 120°C, dehydrated at 0.01MPa for 1 hour, and the system was cooled to 60°C. The isophorone diisocyanate of 111.3 grams, the dib...

Embodiment 3

[0061] 1. Synthesize the acrylate emulsion with anti-ultraviolet function according to the emulsion polymerization method.

[0062] Preparation method: with embodiment 1.

[0063] The raw material composition of emulsion is as follows:

[0064]

[0065] Monomer Type Amount (%)

[0066]

[0067] Styrene 30

[0068] Methyl acrylate 12

[0069] Butyl acrylate 8

[0070] Isooctyl acrylate 45

[0071] 2-Hydroxy-4-acrylate benzophenone 2

[0072] Methacrylic acid 1.5

[0073] N-methylolacrylamide 1.5

[0074]

[0075] 2. Polyurethane emulsion containing double bonds was synthesized by polymerization: 107.3 grams of polytetrahydrofuran diol was added to the reaction kettle, stirred and heated to 120°C, dehydrated at 0.01MPa for 1 hour, and the system was cooled to 60°C, and 105.3 gram of isophorone diisocyanate, after 4 hours of reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com