Heavy caliber paraboloidal mirror checking system

A parabolic mirror and detection system technology, applied in the direction of reflective surface testing, measuring devices, optical instrument testing, etc., can solve the problems of difficult manufacturing, high cost, sensitive installation and adjustment errors, etc., to achieve easy operation, reduce testing costs, and improve detection. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

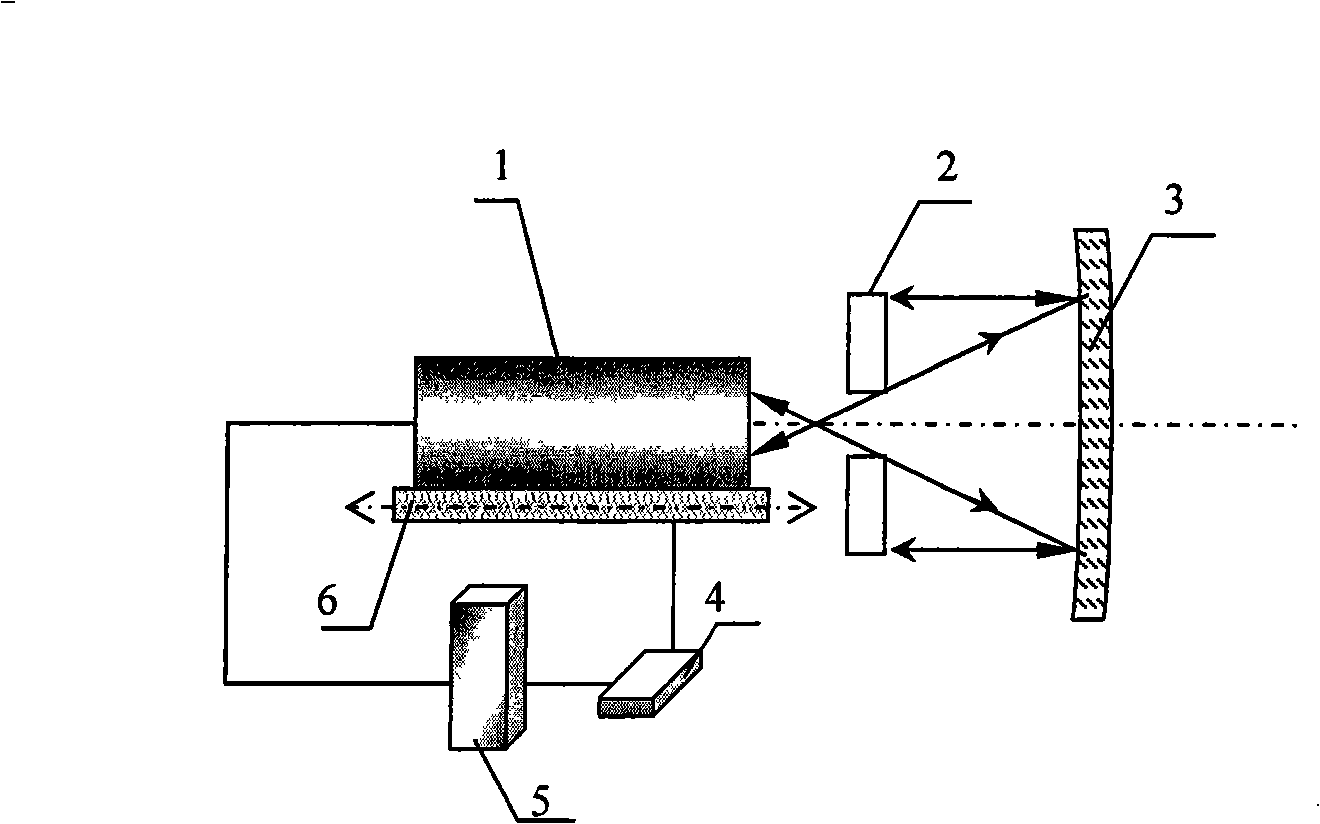

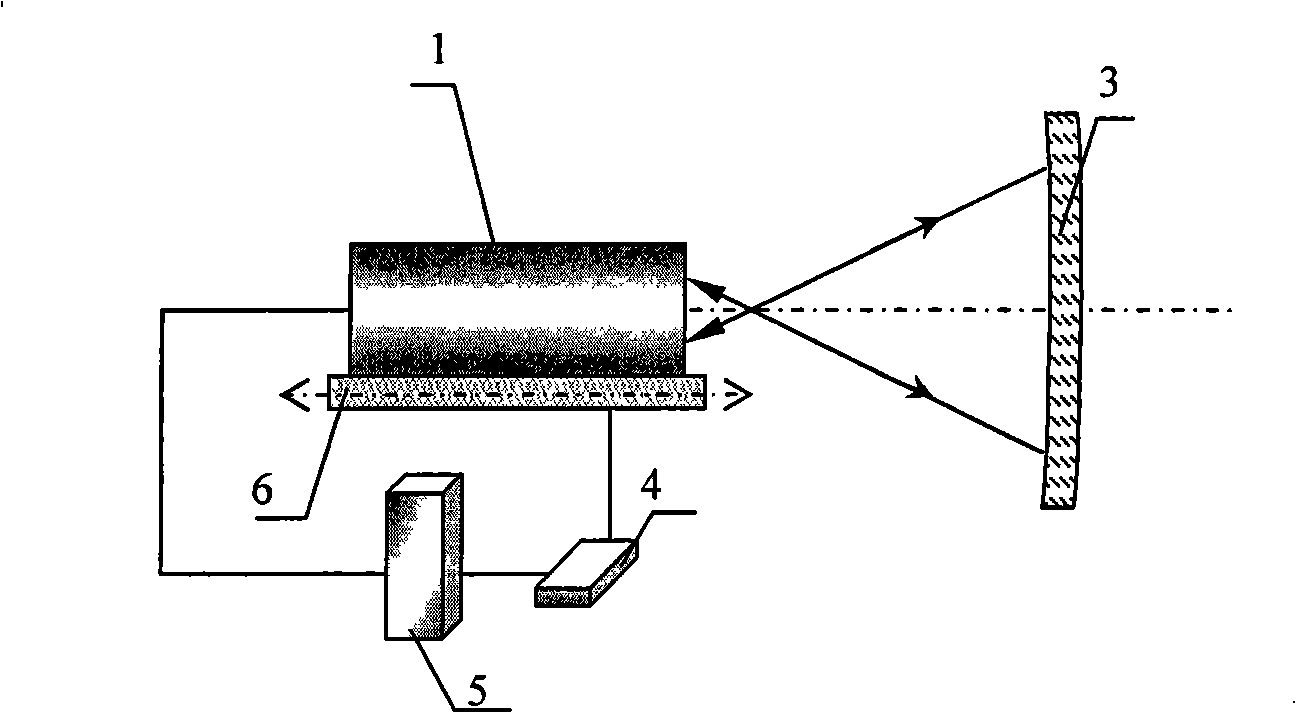

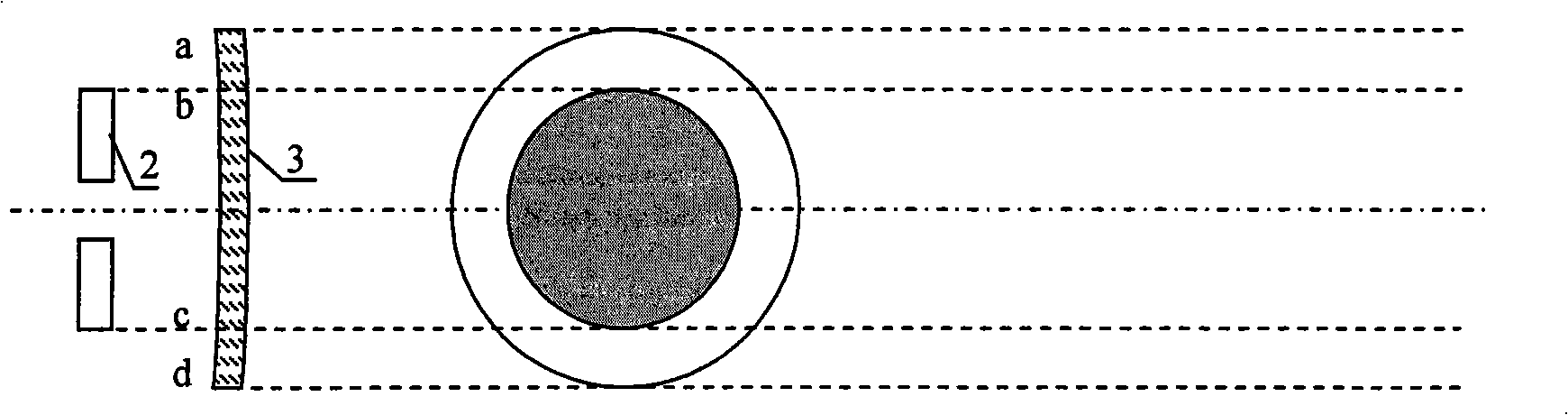

[0023] Such as figure 1 As shown, the present invention is mainly composed of a Fizeau-type interferometer 1, a plane mirror 2, a large-diameter parabolic mirror 3 to be measured, a computer system 5, an electronically controlled translation stage 6 and a digital driver 4, and the Fizeau-type interferometer 1 host Placed on the electronically controlled translation platform 6, the computer system 5 is connected to the electronically controlled translation platform 6 through the digital driver 4, and the computer system 5 controls the Fizeau type interferometer 1 to move precisely in the direction of its optical axis through the digital driver 4, and the measured The large-diameter parabolic mirror 3 is supported by a side support system, and its optical axis coincides with the optical axis of the Fizeau-type interferometer 1 .

[0024] Worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com