Production method of straw fermented feed

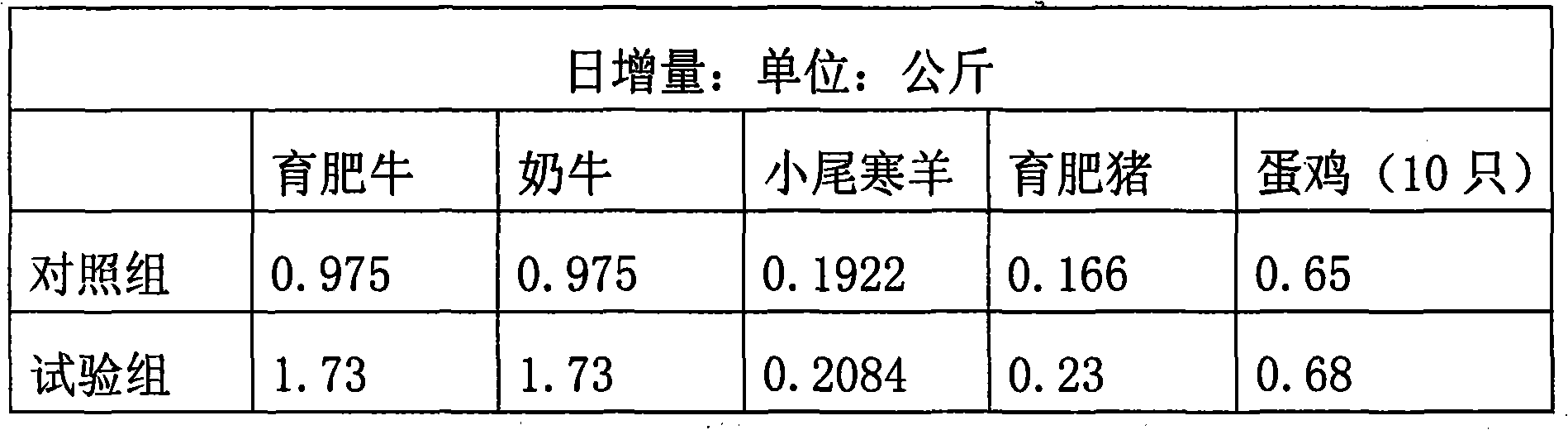

A fermented feed and production method technology, applied in animal feed, animal feed, application, etc., can solve the problems of lack of technology and methods, low crude protein content, etc., and achieve the effects of reducing technical difficulty, high nutritional value, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment one: the production method of straw fermented feed, its steps are mainly:

[0036] 1), cultivation of culture medium: water, sucrose and soybean milk prepare soybean milk culture medium, preparation method is: mix water, soybean milk and sucrose by weight ratio of 85: 15: 2 and adjust pH with 4% hydrochloric acid to be 4.8 ~5.2; the soymilk is a mixed liquid obtained by mixing and grinding dry soybeans and water at a weight ratio of 1:1.

[0037] 2) Selection of strains: choose Biyundong brand edible yeast. The bacterium is produced by Shandong Zouping Yeast Factory. The biological characteristics of the bacterium are: the strain is large, round or oval, Gram staining is positive, it decomposes sucrose to produce acid and gas, and it is active in animal serum or plasma. In the environment of 37°C, blastospores are not produced.

[0038] 3) Straw crushing: use a grinder to crush the straw into 2-3cm granules and weigh them; the straw is one or more of fresh ...

Embodiment 2

[0044] Embodiment two: the straw fermented feed production method, its steps are mainly:

[0045] 1), the cultivation of culture medium: prepare with water, sucrose and animal blood, the preparation method of animal blood culture medium is: mix water, animal blood and sucrose by weight ratio of 90:10:2, adjust with 4% hydrochloric acid The pH of the solution is 4.8~5.2; the animal blood culture solution is obtained. The animal blood can be selected from one or more animal blood including pig, rabbit and chicken.

[0046] 2) Selection of strains: choose Biyundong brand edible yeast. The bacterium is produced by Shandong Zouping Yeast Factory. The biological characteristics of the bacterium are: the strain is large, round or oval, Gram staining is positive, it decomposes sucrose to produce acid and gas, and it is active in animal serum or plasma. In the environment of 37°C, blastospores are not produced.

[0047] 3) Straw crushing: use a grinder to crush the straw into 2-3cm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com