System and process for preparing hydrogen by solar energy middle-low temperature thermal driven thermal chemical reaction

A technology of thermochemical reaction and hydrogen production system, which is applied in the field of conversion systems of medium and low grade energy, can solve problems such as unfavorable large-scale application, low receiver efficiency, complex system cost, etc., and is beneficial to large-scale promotion and application. , low manufacturing and operating costs, and simple system processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

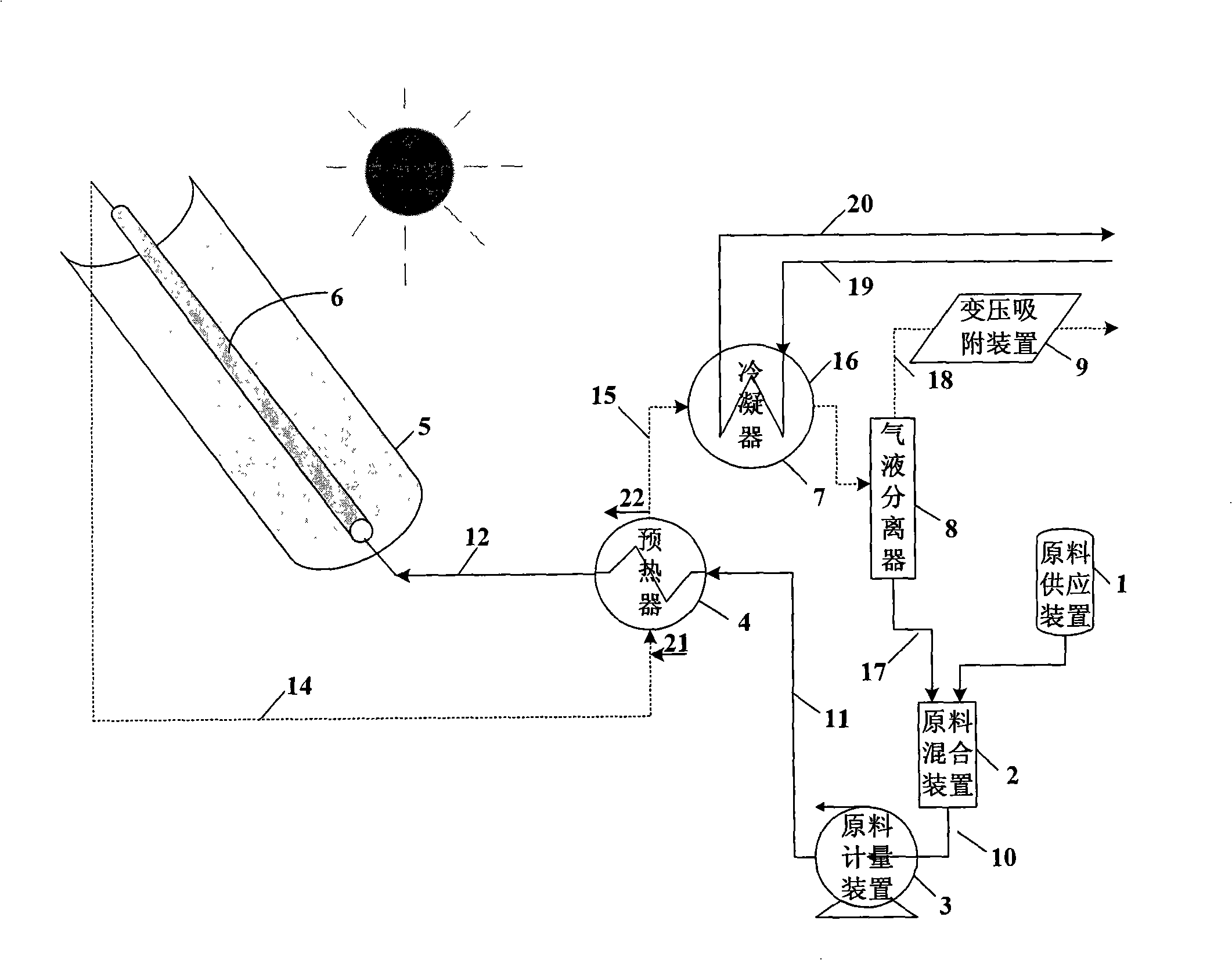

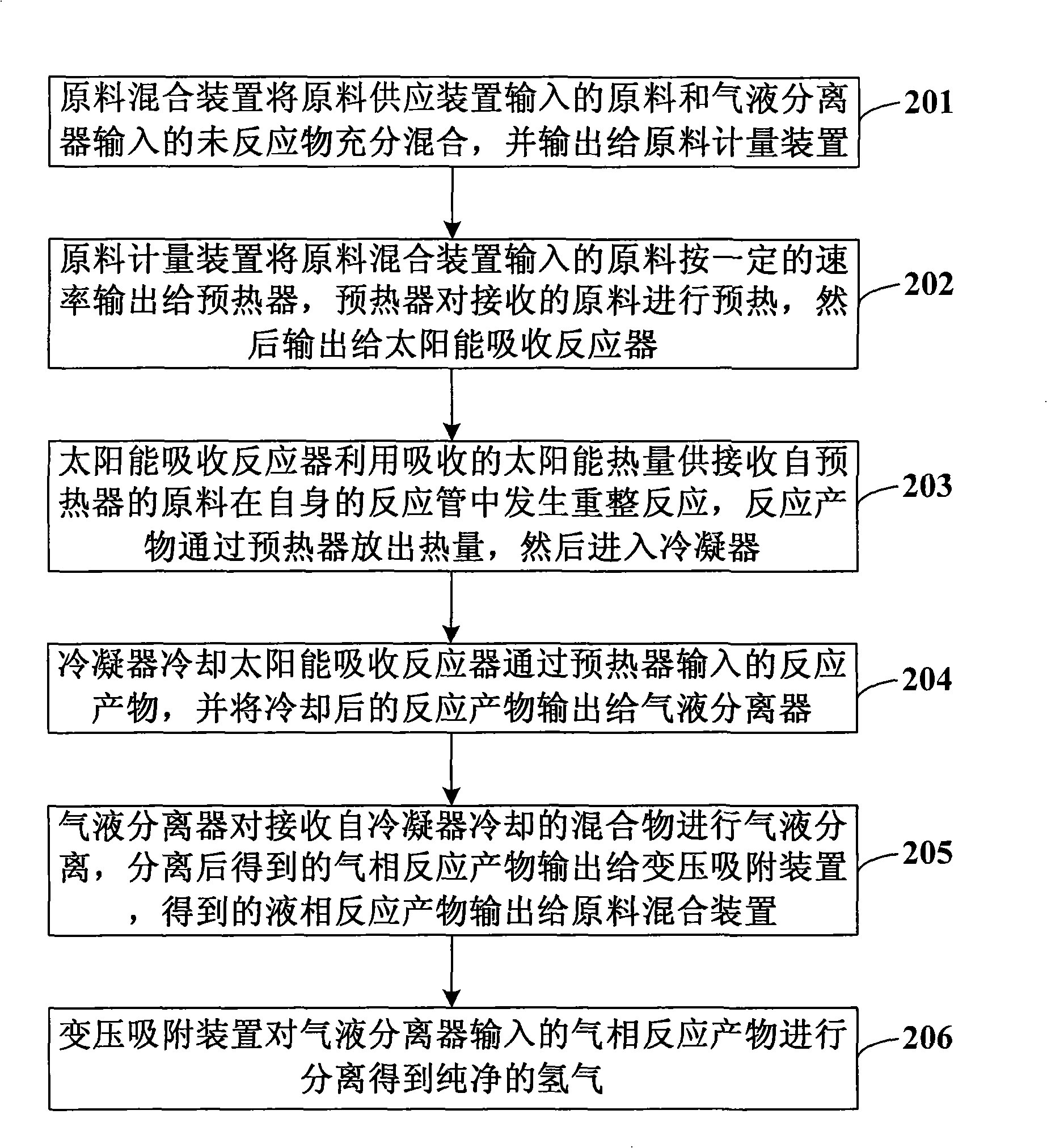

[0087] This embodiment utilizes solar energy, methanol, ethanol or dimethyl ether, and desalted water to perform thermochemical reforming reactions to produce hydrogen. combine Figure 5 , Figure 5 It is a schematic diagram of a thermochemical reaction hydrogen production system driven by solar medium and low temperature heat according to an embodiment of the present invention. The system consists of a solar concentrating device 5, an integrated absorption / reactor 6 and other auxiliary equipment.

[0088] The raw material methanol, ethanol or dimethyl ether (and desalted water) in the raw material mixer 2 passes through the pipeline 10, and is sent to the preheater 4 through the pipeline 11 by the raw material pump 3 at a flow rate of 500-4000ml / h, and then passes through the pipeline 12 Enter the solar absorption reactor 6. The fuel and water are preheated and evaporated in the preheater 4 and the solar absorption reactor 6, and finally become superheated steam. Energy, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com