Fluorescence labeling polyether carboxyl acids antisludging agent and preparation

A technology of polyether carboxylic acid and fluorescent labeling, which is applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., and can solve the problem of inability to realize online measurement and monitoring without fluorescent tracer groups and other problems, to achieve excellent results and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

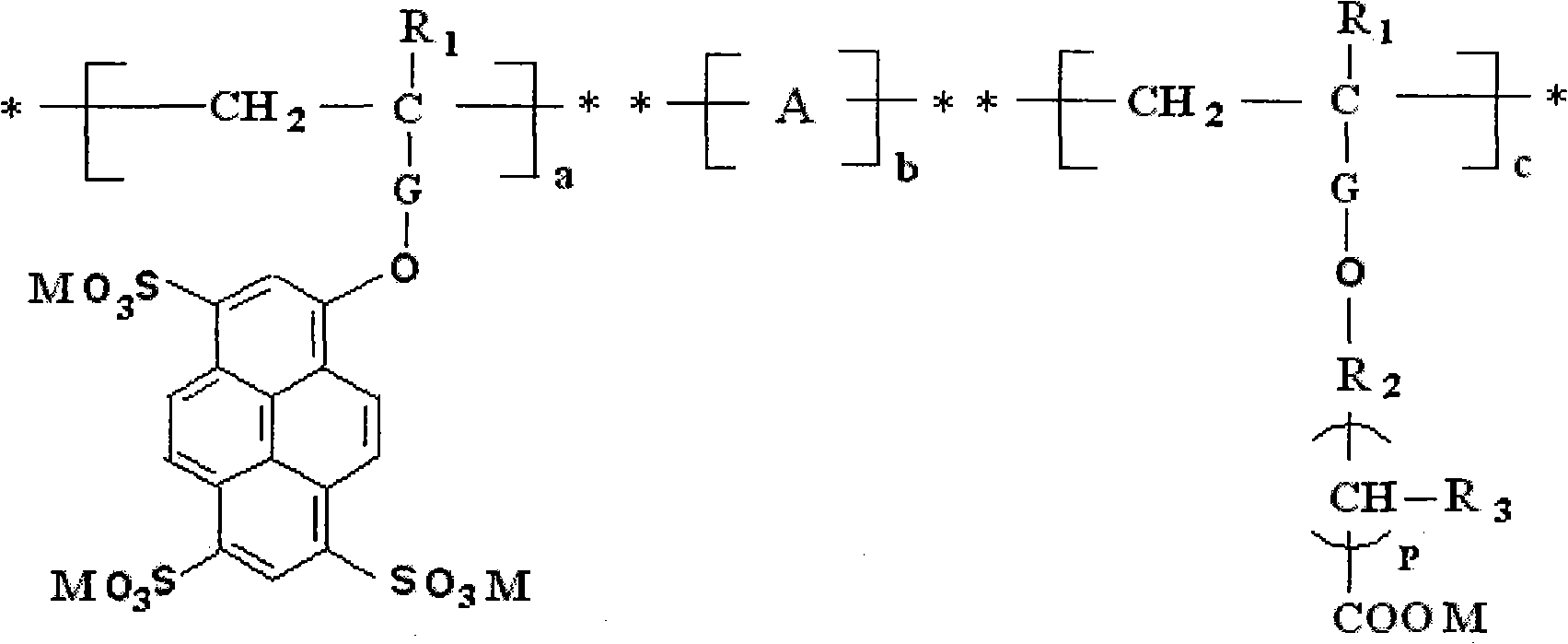

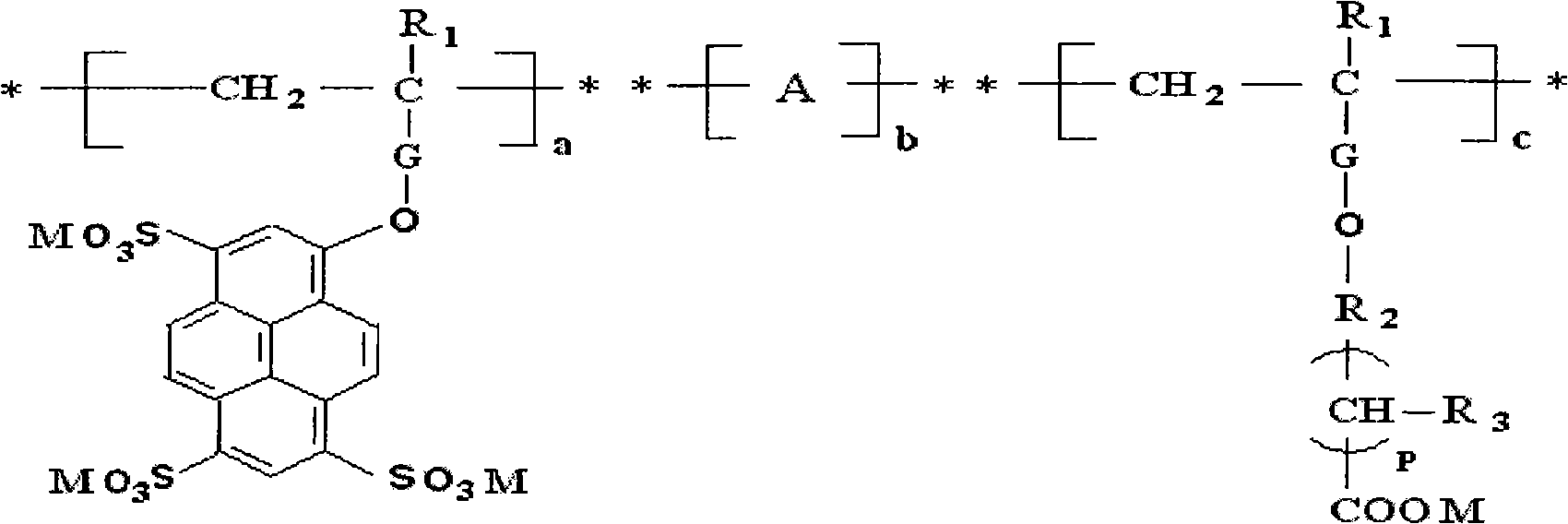

Method used

Image

Examples

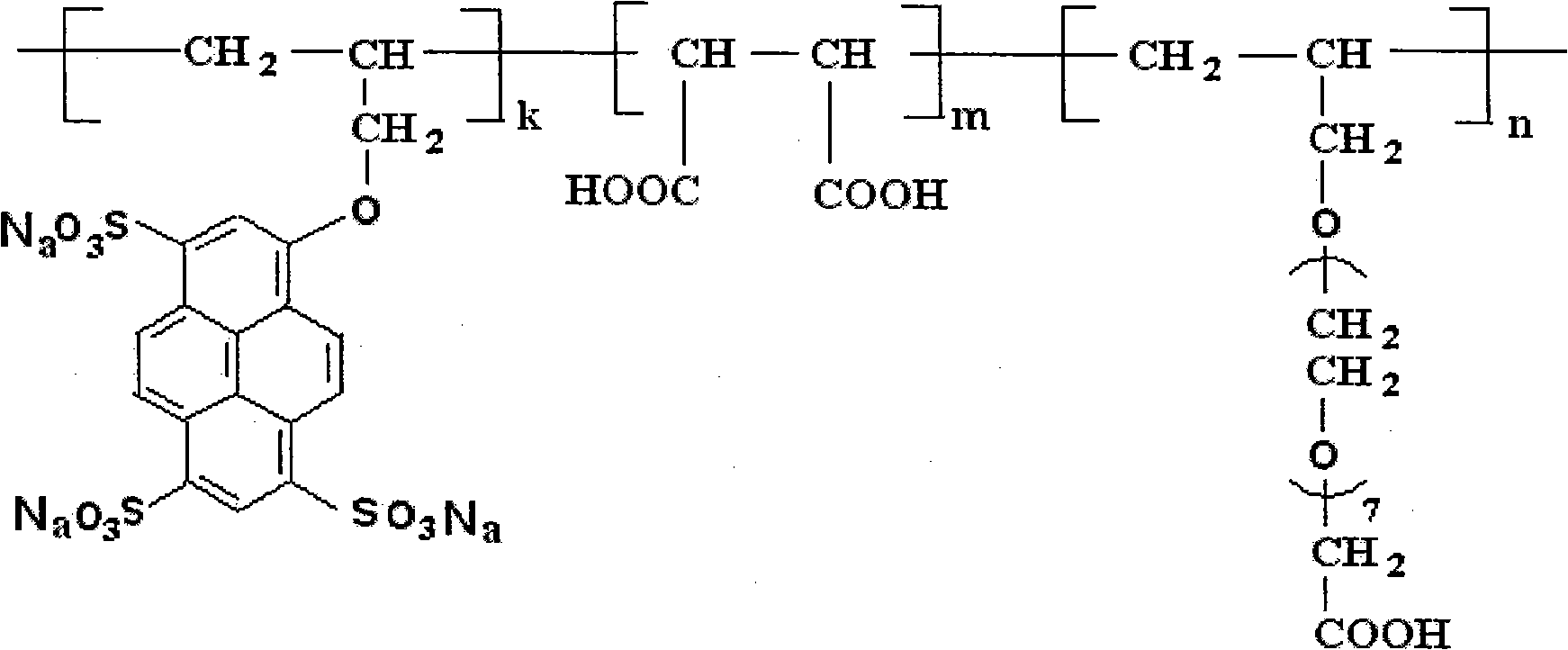

example 1

[0020] Example 1: at N 2 Add 100g allyloxypolyethoxy ether, 80gNaOH in the four-neck flask of protection, under N 2 Under protection, basify at 60°C for 1h to obtain allyloxypolyethoxy sodium. Take by weighing 100g allyloxy polyethoxy sodium, 120g chloroacetic acid, 80g NaOH, in N 2 Carboxymethylation was carried out at 80°C for 6 hours under protection to obtain a mixture of sodium allyloxypolyethoxycarboxylate and allyloxypolyethoxycarboxylate. in N 2Under protection, add 10g 8-hydroxy-1,3,6-pyrene trisulfonate sodium, 50g dimethyl sulfoxide, 3g NaOH, 50g allyl chloride into a four-neck flask, stir at room temperature for 4h, filter, 60℃ After removing dimethyl sulfoxide by distillation under reduced pressure, add acetone 10 times based on the weight of 8-hydroxy-1,3,6-pyrenetrisulfonate sodium, filter, and vacuum dry at 30°C for 48 hours to obtain 8-allyloxy Sodium-1,3,6-pyrenetrisulfonate. Under N2 protection, the mixture of 100g allyloxy polyethoxy sodium carboxylate...

example 2

[0022] Example 2: at N 2 Add 90g allyloxypolypropoxy ether, 70gNaOH in the four-neck flask of protection, under N 2 Alkaline at 70°C for 1 h under protection to obtain allyloxypolypropoxysodium. Take by weighing 100g allyloxy polypropoxy sodium, 100g chloroacetic acid, 50g NaOH, in N 2 Carboxymethylation at 80°C for 6 h under protection to obtain a mixture of sodium allyloxypolypropoxycarboxylate and allyloxypolypropoxycarboxylic acid. in N 2 Under protection, add 10g 8-hydroxy-1,3,6-pyrene trisulfonate sodium, 100g dimethyl sulfoxide, 12g NaOH, 90g allyl chloride into the four-neck flask, stir at room temperature for 4h, filter, 60℃ After removing dimethyl sulfoxide by distillation under reduced pressure, add acetone 10 times based on the weight of 8-hydroxy-1,3,6-pyrenetrisulfonate sodium, filter, and vacuum dry at 30°C for 48 hours to obtain 8-allyloxy Sodium-1,3,6-pyrenetrisulfonate. in N 2 Under protection, the mixture of 100g allyloxy polypropoxy sodium carboxylate...

example 3

[0024] Example 3: at N 2 Add 100g allyloxypolyethoxy ether, 80gNaOH in the four-neck flask of protection, under N 2 Under protection, basify at 60°C for 1h to obtain allyloxypolyethoxy sodium. Take by weighing 100g allyloxy polyethoxy sodium, 120g chlorobutyric acid, 80g NaOH, in N 2 Carboxymethylation at 70°C for 4 hours under protection to obtain a mixture of sodium allyloxypolyethoxycarboxylate and allyloxypolyethoxycarboxylate. in N 2 Under protection, add 20g sodium 8-hydroxy-1,3,6-pyrenetrisulfonate, 80g dimethyl sulfoxide, 10g NaOH, 50g allyl chloride into a four-neck flask, stir at room temperature for 4h, filter, 60°C After removing dimethyl sulfoxide by distillation under reduced pressure, add acetone 9 times the weight of 8-hydroxy-1,3,6-pyrenetrisulfonate based on the weight of sodium pyrenetrisulfonate, filter, and vacuum dry at 30°C for 48 hours to obtain 8-allyloxy Sodium-1,3,6-pyrene trisulfonate. in N 2 Under protection, the mixture of 100g allyloxy poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com