Soft chemistry method for preparing ultrathin HfO* or ZrO* gate dielectric membrane

A technology of gate dielectric and chemical method, which is applied in the field of preparing the above-mentioned ultra-thin HfO2 or ZrO2 gate dielectric thin film by soft chemical method, can solve the problems affecting industrial application, complicated preparation process, easy hydrolysis, etc., and achieves good application prospects and simple process , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

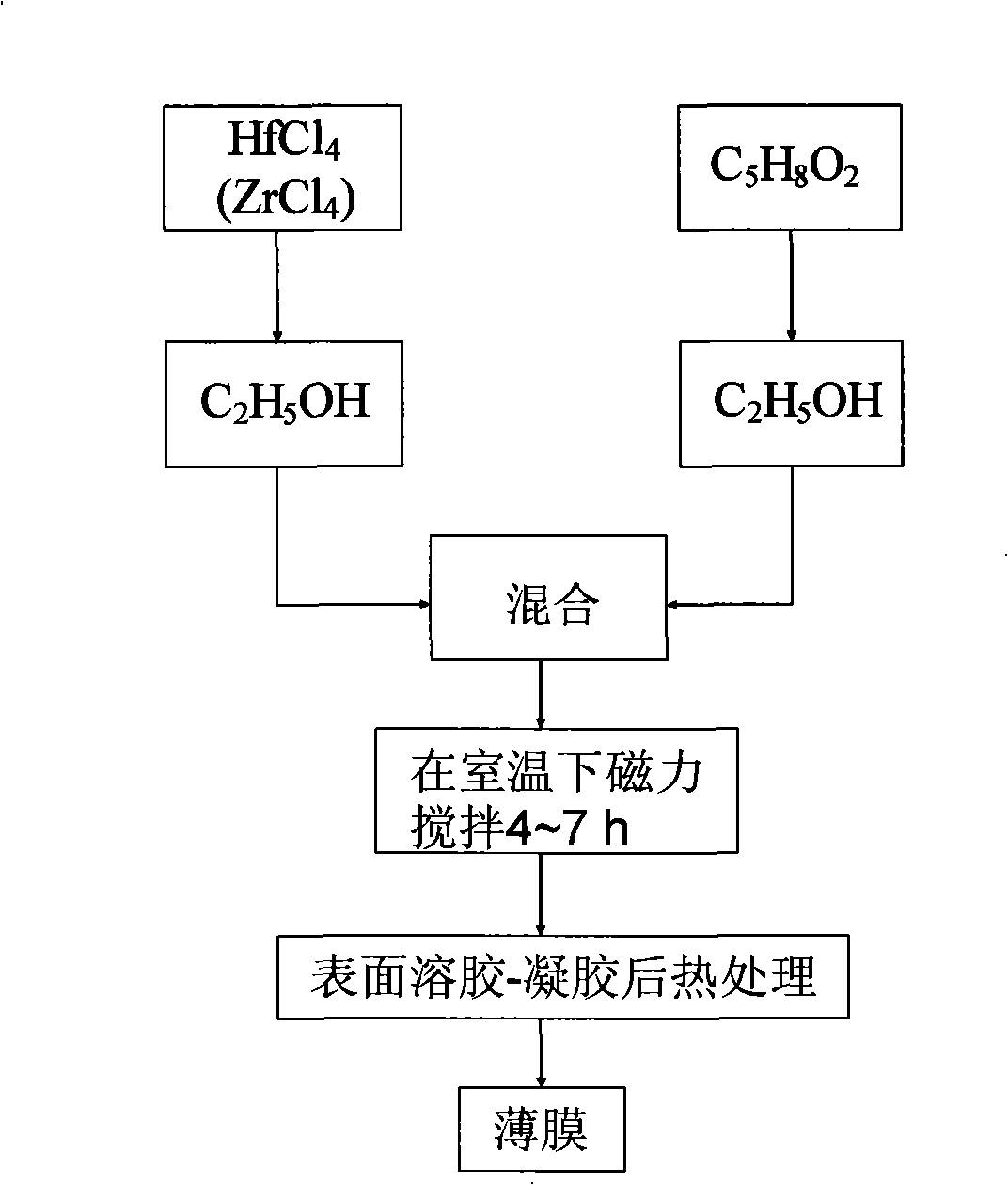

[0027] (1) HfCl 4 Preparation of sol:

[0028] Take 0.01mol of anhydrous HfCl in a hand-held box under nitrogen atmosphere 4 Dissolve the powder in 30ml of absolute ethanol, stir to make it completely dissolved; mix 5ml of acetylacetone with 15ml of absolute ethanol, then mix the above two solutions; then take out the prepared solution from the hand box and leave it at room temperature Magnetic stirring for 4-7 hours to obtain stable HfCl with a concentration of about 0.2mol / l 4 Sol

[0029] (2) Si substrate processing:

[0030] After the single crystal silicon substrate is cleaned by standard RCA semiconductor cleaning process, it is then immersed in a diluted hydrofluoric acid solution at room temperature for 3 to 6 minutes to remove the oxide layer on the surface (the volume ratio of hydrofluoric acid to deionized water is 1 : 8); Then put the substrate into 30% (mass fraction) hydrogen peroxide at 60°C for ultrasonic treatment for 8-15 minutes;

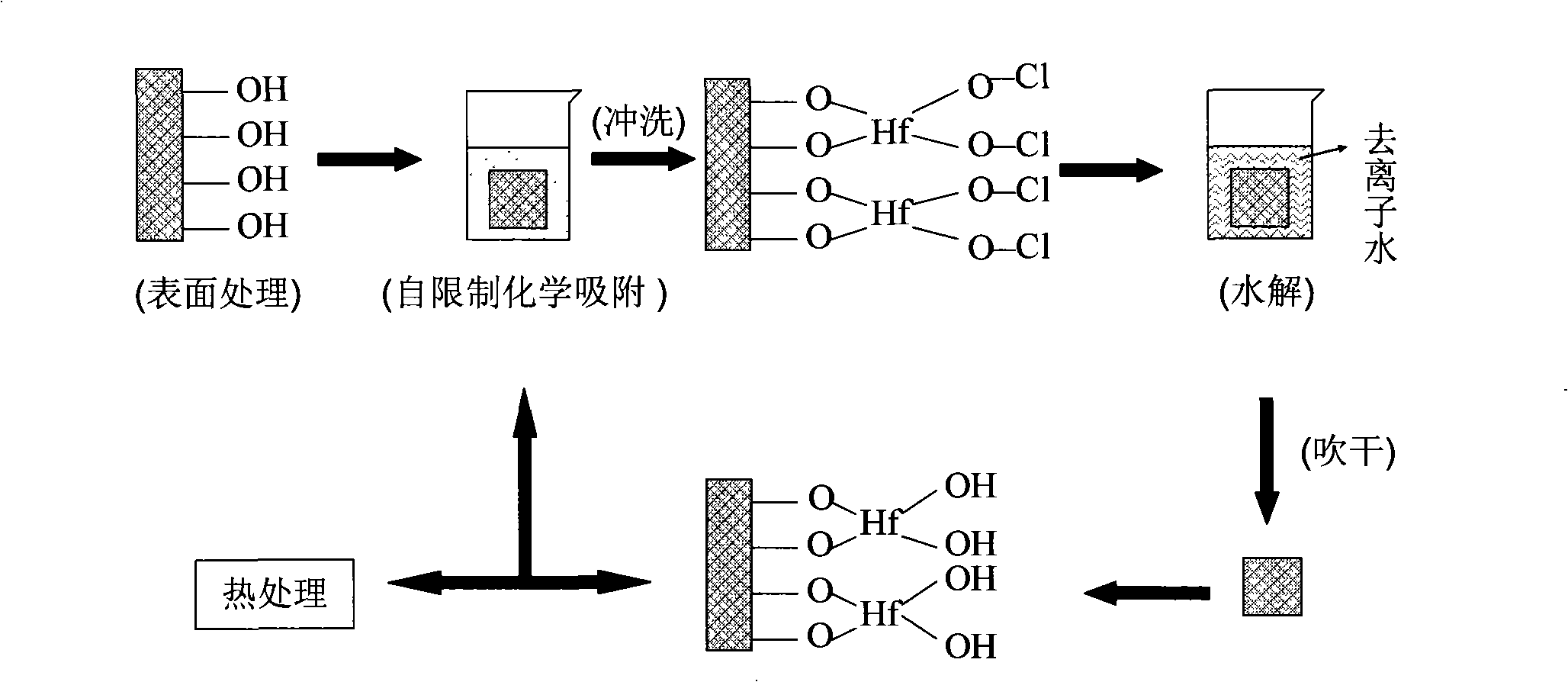

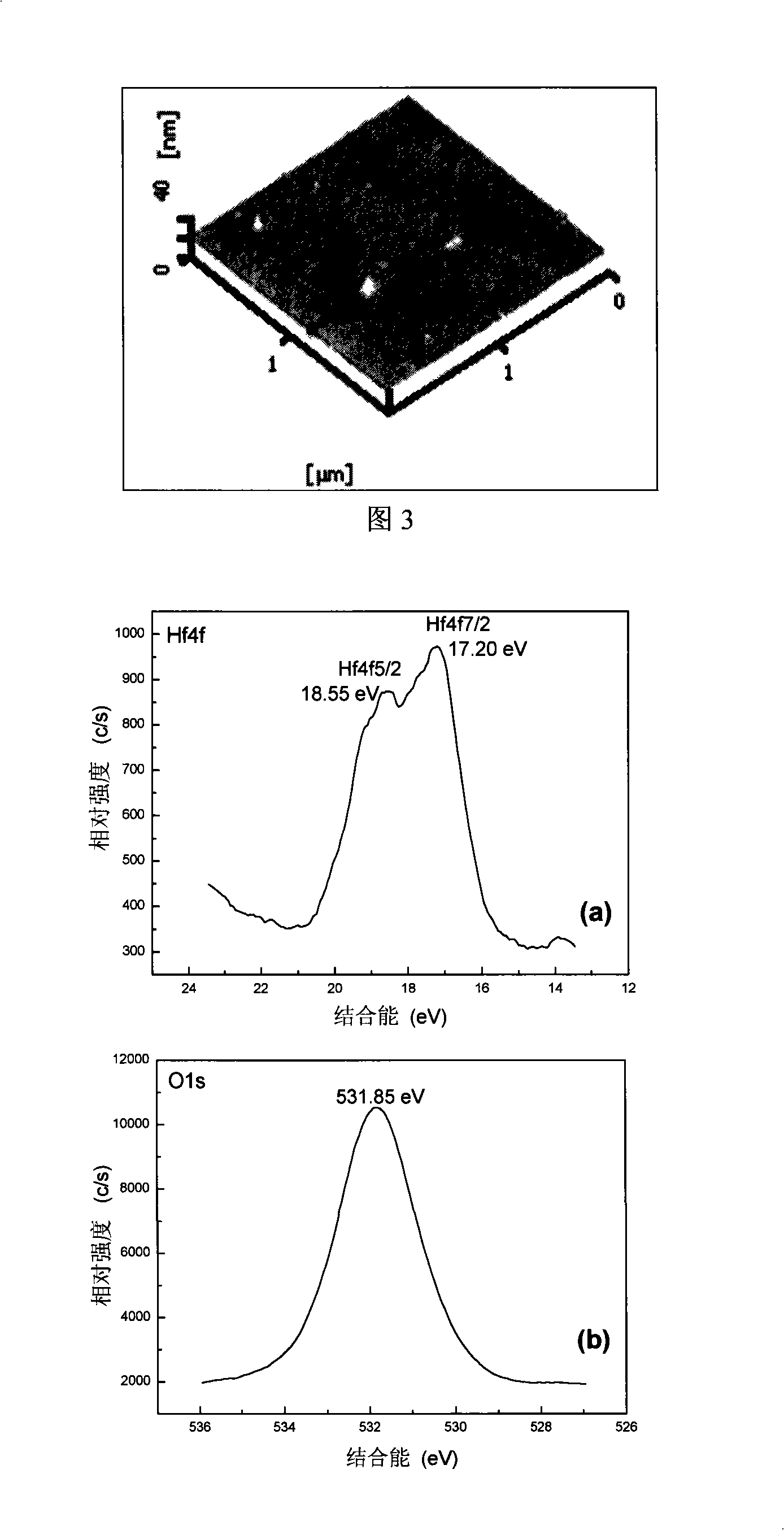

[0031] (3) Film preparation pr...

Embodiment 2

[0038] (1) HfCl 4 Preparation of sol:

[0039] Take 0.005mol of anhydrous HfCl in a hand-held box under nitrogen atmosphere 4 Dissolve the powder in 20ml of absolute ethanol and stir to completely dissolve it; mix 3ml of acetylacetone with 17ml of absolute ethanol, then mix the above two solutions; then take out the prepared solution from the hand box and leave it at room temperature Magnetic stirring for 4-7 hours to obtain stable HfCl with a concentration of about 0.125mol / l 4 Sol

[0040] (2) Si substrate processing:

[0041] After the single crystal silicon substrate is cleaned by standard RCA semiconductor cleaning process, it is then immersed in a diluted hydrofluoric acid solution at room temperature for 3 to 6 minutes to remove the oxide layer on the surface (the volume ratio of hydrofluoric acid to deionized water is 1 : 10); Then put the substrate in 30% by weight hydrogen peroxide at 50°C and ultrasonically treat it for 8-15 minutes;

[0042] (3) Film preparation proces...

Embodiment 3

[0049] (1) HfCl 4 Preparation of sol:

[0050] Take 0.02mol of anhydrous HfCl in a hand-held box under nitrogen atmosphere 4 Dissolve the powder in 40ml of absolute ethanol and stir to dissolve it completely; mix 6ml of acetylacetone with 20ml of absolute ethanol, then mix the above two solutions; then take out the prepared solution from the hand box and leave it at room temperature Stir magnetically for 4-7 hours to obtain stable HfCl with a concentration of about 0.3mol / l 4 Sol

[0051] (2) Si substrate processing:

[0052] After the single crystal silicon substrate is cleaned by standard RCA semiconductor cleaning process, it is then immersed in a diluted hydrofluoric acid solution at room temperature for 3 to 6 minutes to remove the oxide layer on the surface (the volume ratio of hydrofluoric acid to deionized water is 1 : 8); Then put the substrate into 30% (mass fraction) hydrogen peroxide at 50°C for ultrasonic treatment for 8-15 minutes;

[0053] (3) Film preparation proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com