Technique for preparing tartary buckwheat sweet fermented glutinous rice

A production process and a technology for sweet wine brewing, which is applied in the field of production technology of bitter buckwheat sweet wine brewing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Embodiment 1, a kind of production technology of tartary buckwheat glutinous rice wine comprises the following steps: 1, get the water of 4 times of weight of tartary buckwheat rice,

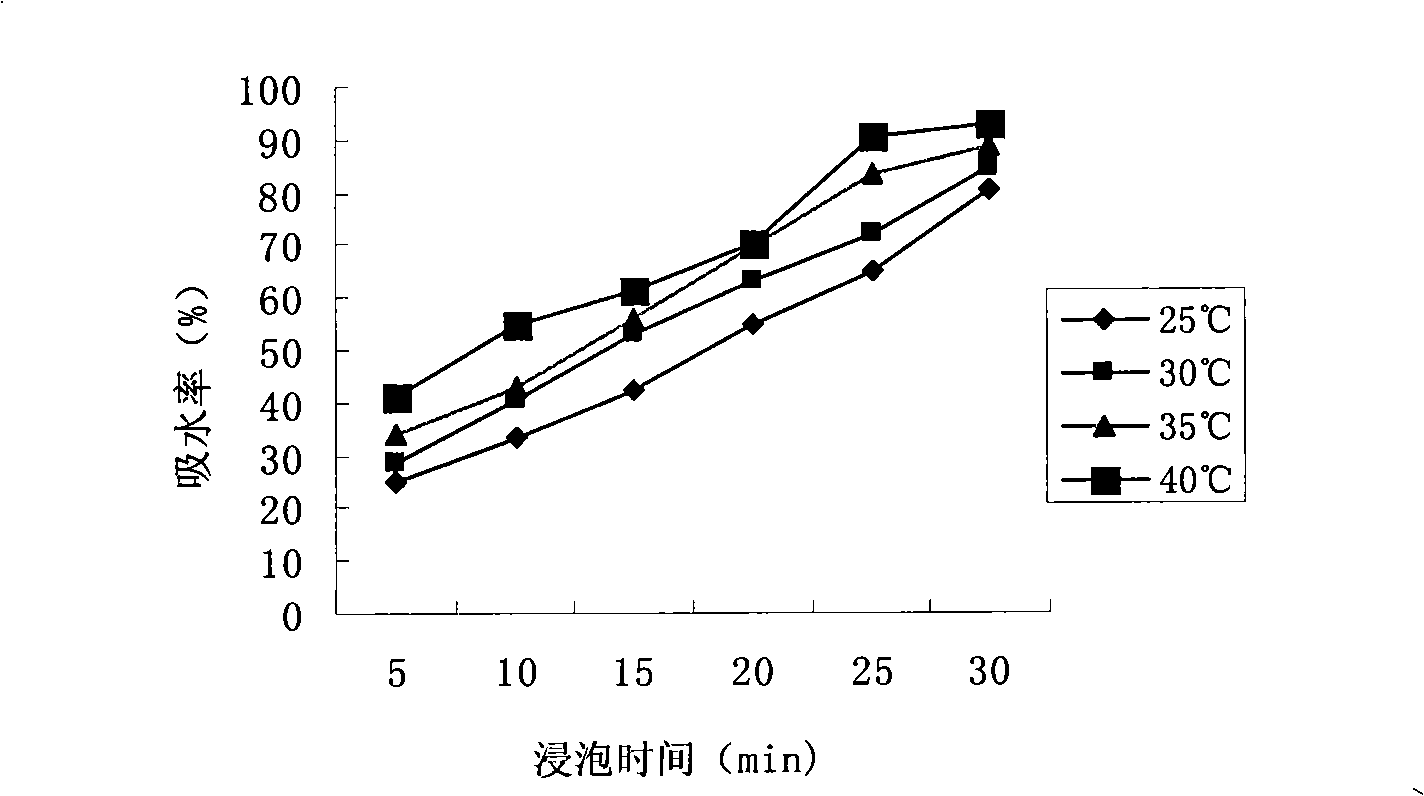

[0095] 2. Soak for 10 minutes at a temperature of 40°C.

[0096] 3. Steam rice for 10 minutes,

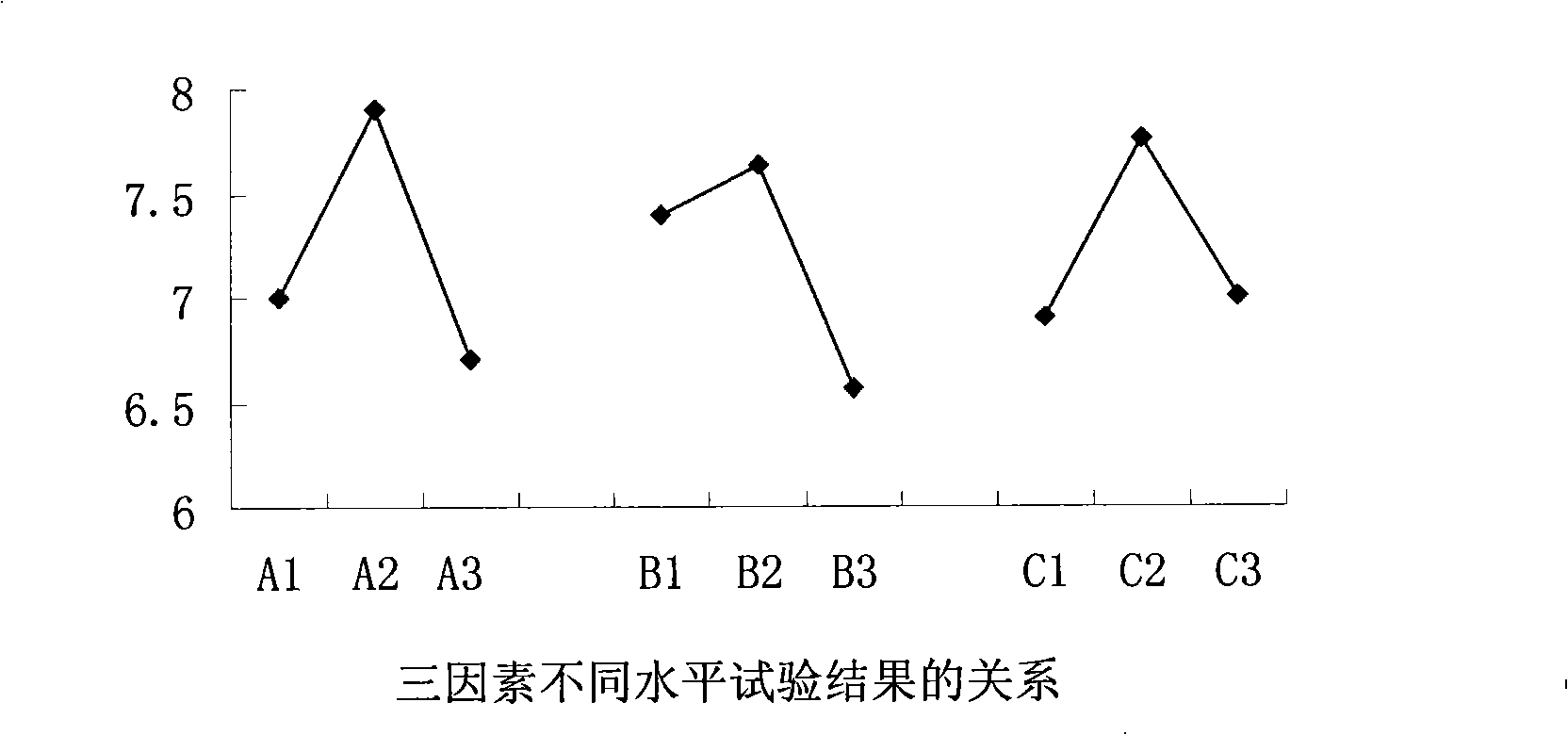

[0097] 4. Cool to 30°C, add 1% (weight ratio) of tartary buckwheat koji.

[0098] 5. Bottle it and ferment for 30 hours at 40°C.

[0099] 6. For blending, maltose or white sugar is added before fermentation, so that the sugar content of the brewing liquid reaches 20.0 (20°C, BX), and then natural plant substances with fragrance are added, such as sweet-scented osmanthus, wolfberry, lotus seeds, etc.

[0100] 7. Sterilize at 80-85°C for 10-30 minutes. Cool quickly to below 40°C after sterilization.

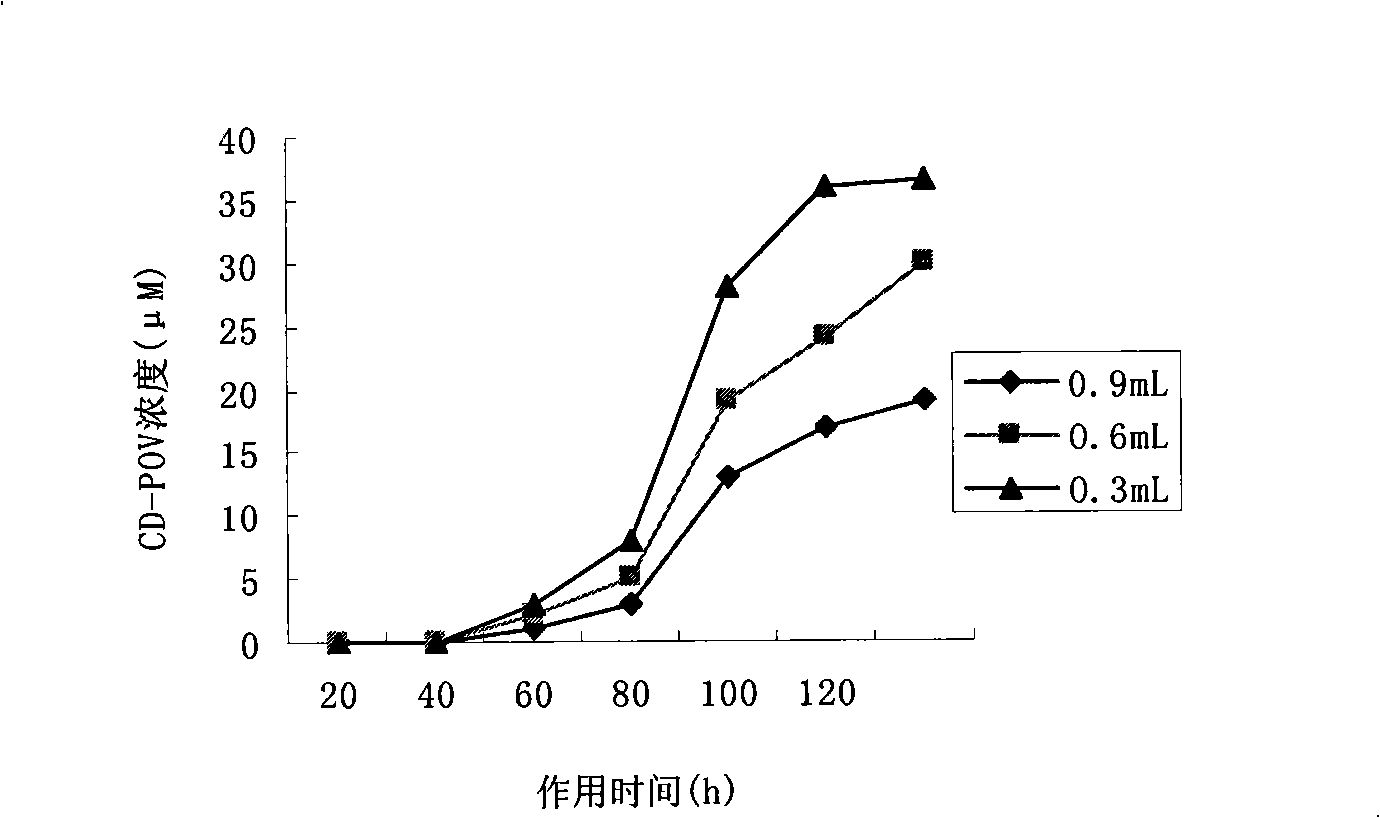

[0101] The production method of tartary buckwheat koji,

[0102] 1. Preparation of bran culture medium Add water 70% (W / W weight ratio) to fresh bran for cultivating Rhizopus; add water 60% (W...

Embodiment 2

[0107] Embodiment 2, a kind of production technology of tartary buckwheat glutinous rice wine comprises the following steps:

[0108] 1. Take tartary buckwheat rice and add 6 times the weight of water,

[0109] 2. Soak for 30 minutes at a temperature of 25°C.

[0110] 3. Steam the rice for 3 minutes,

[0111] 4, be cooled to 30 ℃, add tartary buckwheat koji 5% (weight ratio).

[0112] 5. Bottle and ferment for 60 hours at 20°C.

[0113] 6. Blending, adding maltose or white sugar afterwards, so that the sugar content of the brewing liquid reaches 20.0 (20°C, BX). Natural plant substances can also be added for decoration, such as sweet-scented osmanthus, wolfberry, lotus seeds, etc.

[0114] 7. Sterilize at 80-85°C for 10-30 minutes. Cool quickly to below 40°C after sterilization.

Embodiment 3

[0115] Embodiment 3, a kind of production technology of tartary buckwheat fermented glutinous rice comprises the following steps: 1, get the water of 5 weights of tartary buckwheat rice,

[0116] 2. Soak for 20 minutes at a temperature of 2°C.

[0117] 3. Steam the rice for 5 minutes,

[0118] 4, be cooled to 30 ℃, add tartary buckwheat koji 2% (weight ratio),

[0119] 5. Bottle it and ferment for 50 minutes at 3°C.

[0120] 6. For blending, maltose or white sugar can be added before or after fermentation according to needs, so that the sugar content of the brew can reach 20.0 (20°C, BX), and natural plant substances can also be added as embellishments, such as sweet-scented osmanthus, wolfberry, lotus seeds, etc.

[0121] 7. Sterilize at 80-85°C for 10-30 minutes. Cool quickly to below 40°C after sterilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com