Device for removing CO2 of flue gas by highly active potassium-base absorbing agent dry method and method thereof

A high-activity potassium and absorbent technology, applied in separation methods, chemical instruments and methods, air quality improvement, etc., can solve problems such as temperature rise in the carbonation reaction system and affect the normal progress of the carbonation reaction, so as to save investment and The effects of low operating costs, equipment and operating costs, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

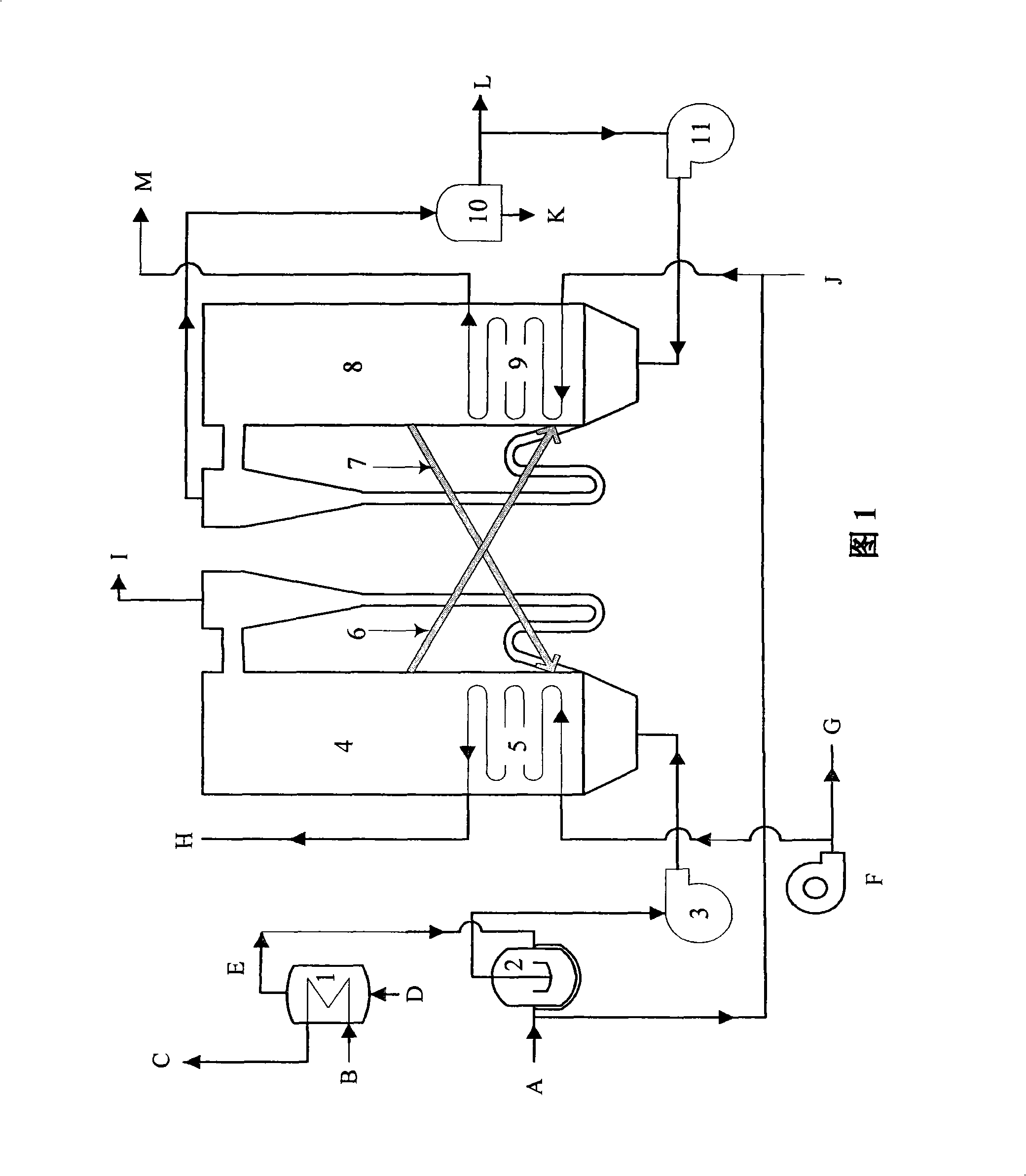

[0026] The high activity potassium-based absorbent of the present invention removes CO in flue gas by dry method 2 The device is composed of steam generator, gas mixer, booster fan, carbonation reactor, buried tube radiator, material circulation device, regeneration reactor, buried tube heater, steam condenser and circulating fan, etc. .

[0027] The high activity potassium-based absorbent of the present invention removes CO in flue gas by dry method 2 The process flow is: the flue gas after desulfurization is mixed with a certain amount of water vapor (if the content of water vapor in the flue gas after desulfurization treatment is sufficient for the carbonation reaction, the water steam generator may not be installed) and sent by the booster fan into the carbonation reactor, where it reacts with highly active potassium-based absorbents to remove the CO in the flue gas 2 Removal; the reacted absorbent enters the regeneration reactor through the material circulation device I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com