Metal tailings construction nucleated glass and one-step sintering preparation thereof

A technology of glass-ceramics and metal tailings, which is applied in the field of metal tailings building glass-ceramics and its primary sintering preparation, can solve the problems of high energy consumption, high product cost, high melting temperature, etc. Improved weatherability and reduced environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

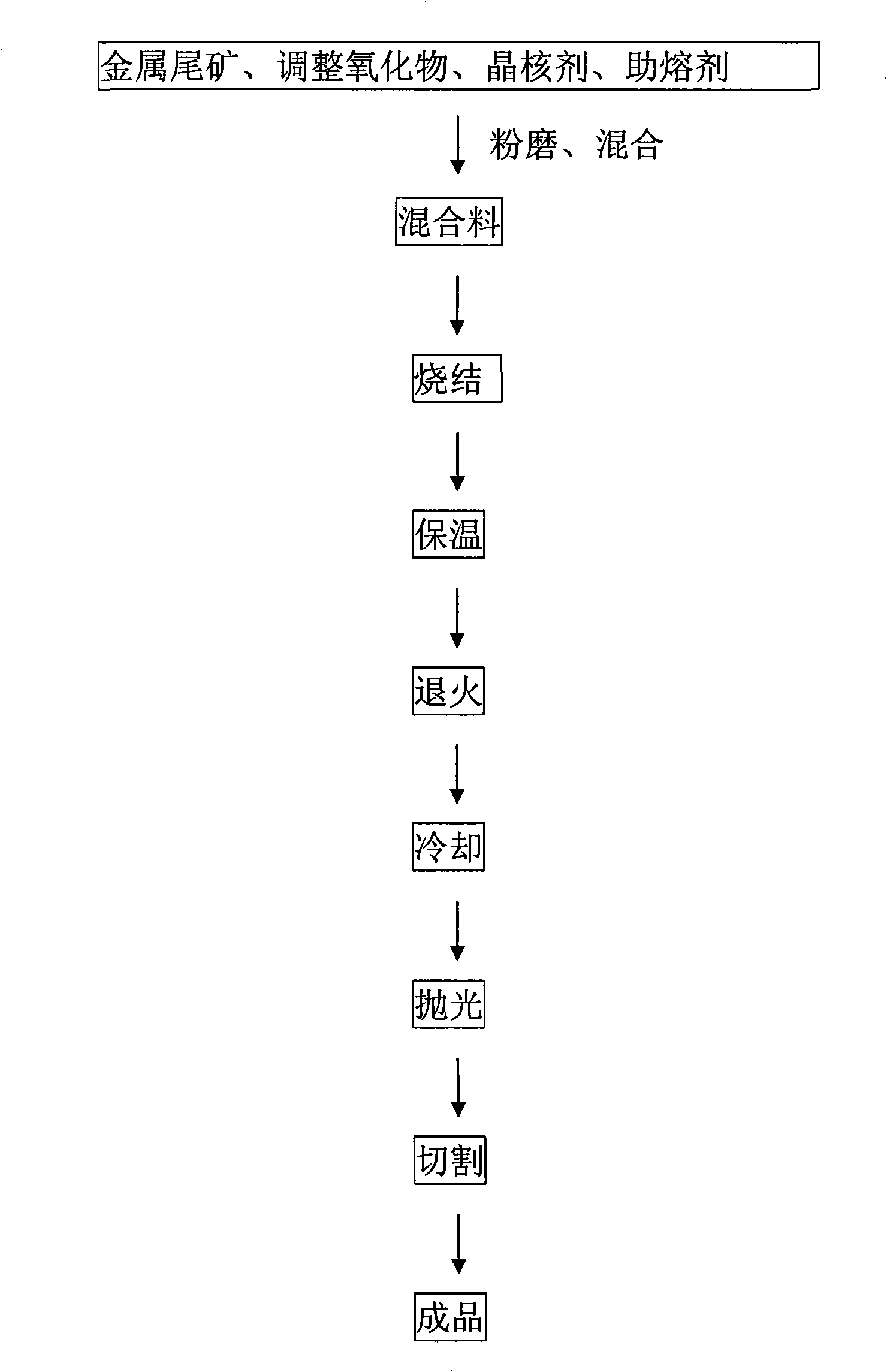

Method used

Image

Examples

Embodiment 1

[0022] This embodiment provides a kind of high-performance metal tailings building glass-ceramic, and its raw material is composed of iron tailings in Waitoushan, Liaoning, adjustment oxide, flux and TiO 2 and Cr 2 o 3 Composite crystal nucleating agent, wherein the addition amount of each constituent raw material is (mass fraction): 62.0% of the iron tailings of Waitoushan; 8.0% of dolomite; 11.0% of limestone; 6.0% of kaolin; K 2 SO 4 1.5%;K 2 CrO 4 3.1%;Na 2 CO 3 2.0%; BaSO 4 2.1%; ZnO 0.8%; CaF 2 1.5%;TiO 2 2.0%. The function of each component is: the iron tailings of Waitoushan is the most basic raw material for the production of architectural glass-ceramics, mainly providing SiO 2 、Al 2 o 3 , CaO, MgO and other chemical components; dolomite mainly corrects the deficiency of MgO in iron tailings; limestone mainly corrects the deficiency of CaO in iron tailings; kaolin mainly corrects the deficiency of Al in iron tailings 2 o 3 Insufficient; K 2 SO 4 ...

Embodiment 2

[0030] The difference from Example 1 is:

[0031] This embodiment provides a kind of high-performance metal tailings building glass-ceramic, and its raw material is composed of Liaoning Xincheng gold mine tailings, adjustment oxide, flux and TiO 2 and Cr 2 o 3 Composite crystal nucleating agent, wherein the addition of each constituent raw material is (mass fraction): Xincheng gold mine tailings 60.1%; Dolomite 8.0%; Limestone 10.0%; Feldspar 4.0%; K 2 SO 4 2.0%;K 2 CrO 4 1.6%; BaSO 4 2.0%;Na 2 CO 3 3.3%; ZnO 0.7%; CaF 2 3.5%; Fe 2 o 3 2.0%;TiO 2 2.8%. Among them, the tailings of Xincheng Gold Mine are the most basic raw materials for the production of architectural glass-ceramics, mainly providing SiO 2 、Al 2 o 3 , CaO, MgO and other chemical components; feldspar is mainly to correct SiO in gold mine tailings 2 and Al 2 o 3 ;K 2 SO 4 Mainly to provide K 2 O, to promote the formation of microcrystalline structure; K 2 CrO 4 Mainly to provide Cr 2 ...

Embodiment 3

[0037] The difference with embodiment 1 and embodiment 2 is:

[0038] This embodiment provides a kind of high-performance metal tailings building glass-ceramic, and its raw material is composed of iron tailings in Waitoushan, Liaoning, adjustment oxide, flux and TiO 2 and Cr 2 o 3 Composite crystal nucleating agent, wherein the addition amount of each constituent raw material is (mass fraction): 60.0% of the iron tailings of Mount Waitoushan; 9.8% of dolomite; 11.0% of limestone; 7.0% of kaolin; K 2 SO 4 1.2%;K 2 CrO 4 3.1%; BaSO 4 2.1%;Na 2 CO 3 2.0%; ZnO 0.9%; CaF 2 0.9%;TiO 2 2.0%.

[0039]The optimal process of building glass-ceramic with this formula is as follows: mix, grind, and pass through a 0.080mm square hole sieve to prepare the batch material, and mix the Raise the temperature to 1300°C at a rate of 7°C / min, keep it warm for 75 minutes, anneal at 670°C, keep it warm for 20 minutes, and then cool naturally. The composition of the obtained glass-cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com