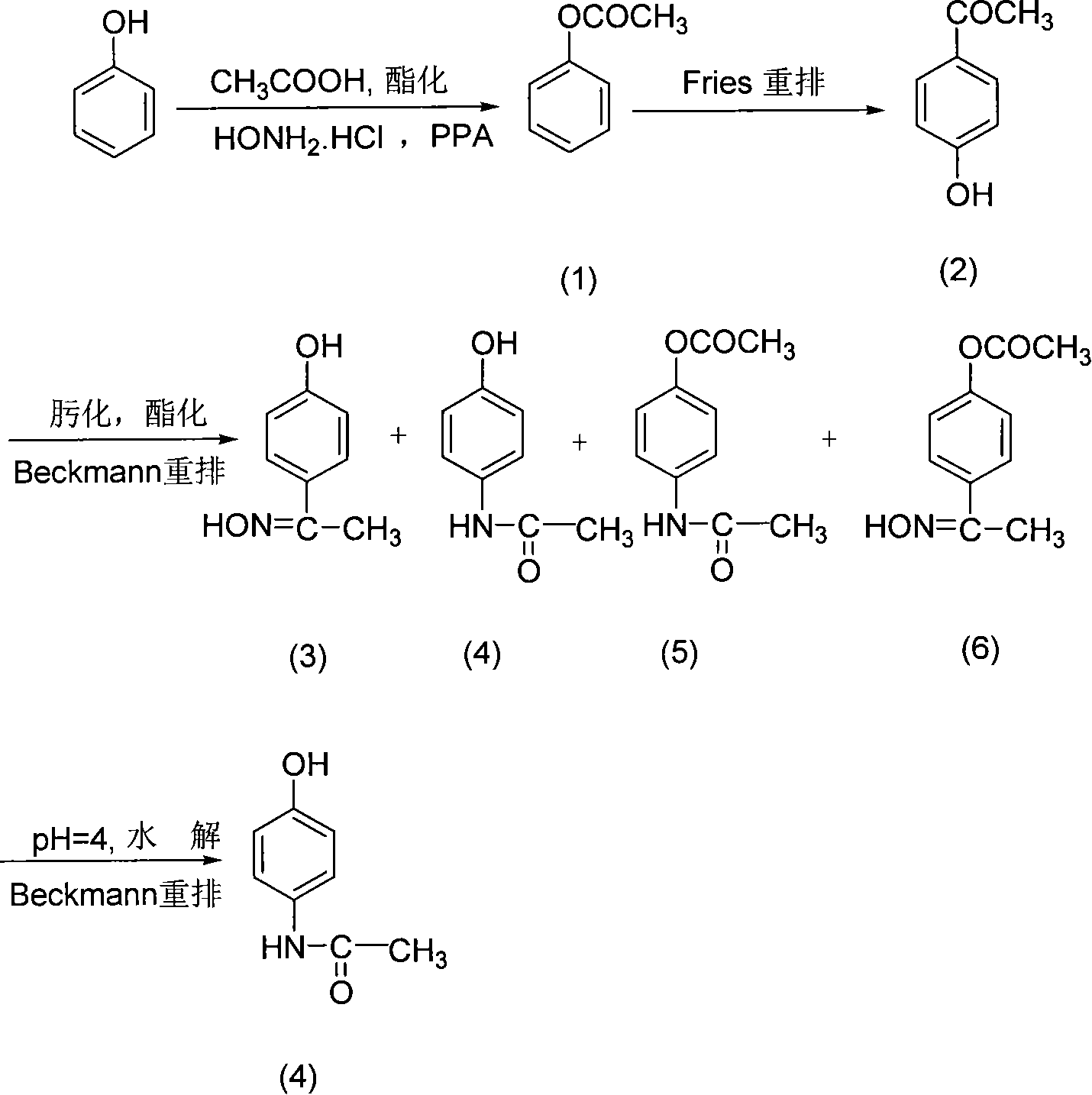

Preparation process of p-acetaminophenol

A technology for the preparation of acetaminophenol, which is applied in the field of polyphosphoric acid as a catalyst, can solve the problems of increasing the production cost of acetaminophenol and the high price of the catalyst, and achieve the effects of suppressing side reactions, low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Add 1.0g of phenol, 0.93g of hydroxylamine hydrochloride, 3.2g of acetic acid and 9.2g of polyphosphoric acid into a 300ml three-neck round bottom flask, seal the reactor and react in an oil bath at 80°C for 5.2h, cool slightly, add about 100ml of ice water, Use ammonia water to adjust the pH to 4, pass nitrogen into the three-neck round bottom flask to replace the air 3 times, add 1.0 g of sodium bisulfite, then seal the reactor, continue to reflux in an oil bath at 112 °C for 6.2 h, cool down, and depressurize Evaporate the solvent water to dryness, wash 3 times with (40×3)ml acetone, filter out the ammonium phosphate salt, and recycle it as a fertilizer, combine the filtrates, evaporate the solvent to obtain the crude product, recrystallize with water to obtain white crystals, calculated as raw material phenol The total yield was 75.49%. 1 HMNR (400MHz, d 6 -DMSO) δ: 9.64 (s, 1H, NH), 9.14 (s, 1H, OH), 7.30-7.33 (m, 1H, Ar-H), 6.64-6.67 (m, 1H, Ar-H), 1.96 (s, 3H, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com