Gelatine/biological activity glass composite sponge dressing and preparation thereof

A bioactive glass, composite sponge technology, applied in bandages, absorbent pads, medical science and other directions, can solve problems such as unfavorable large-scale application and high price of type I collagen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

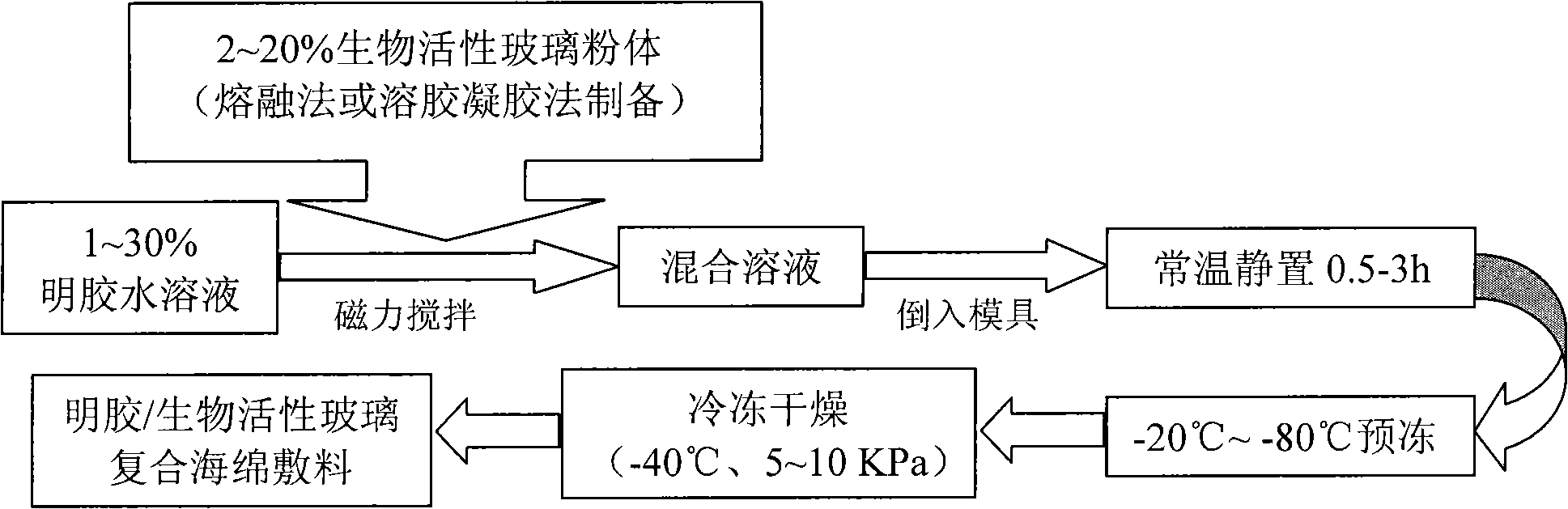

Method used

Image

Examples

Embodiment 1

[0035] Bioactive glass powder was prepared by fusion method, and analytically pure SiO 2 , Na 2 CO 3 , CaCO 3 , P 2 o 5 The raw materials are uniformly mixed in proportion, melted at 1420°C to form a homogeneous melt, then cooled, pulverized, and sieved to obtain bioactive glass powder with a particle size of 40-300 μm. The mass percentage of the glass powder consists of CaO 24.5%, SiO 2 45%, Na 2 O 24.5%, P 2 o 5 6%.

[0036] Dissolve gelatin in deionized water at a temperature of 40°C to 60°C to prepare a gelatin aqueous solution with a mass concentration of 2%; add 5% by mass of biological particles with a particle size of 100-150 μm to the gelatin solution Active glass powder, magnetically stirred for 3 hours to disperse the glass powder evenly; pour the mixed solution into the mold until the liquid layer reaches 2mm, let it stand at room temperature for 1 hour, then put it into -75℃ for 1 hour, and put the pre- The frozen gel was freeze-dried in a vacuum freez...

Embodiment 2

[0038] Preparation of bioactive glass powder by sol-gel method, using tetraethyl orthosilicate (TEOS) as SiO 2 The precursor of triethyl phosphate (TEP) as P 2 o 5 precursors. Under the catalysis of nitric acid, hydrolyze in aqueous solution, then add nitrate and mix well to form a sol. The prepared sol is aged at 60°C for 72 hours to form a gel, and then dried at 120°C for 72 hours, ball milled and sieved The obtained xerogel powder is calcined at 700° C. to obtain bioactive glass powder with a particle size of 1-40 μm. The composition of the glass powder is SiO 2 58%, CaO 33%, P 2 o 5 9%.

[0039] Dissolve gelatin in deionized water at a temperature of 40°C to 60°C to prepare a gelatin aqueous solution with a mass percent concentration of 2.5%; add 10% mass percent of the gelatin solution with a particle size of 1-40 μm The bioactive glass powder is magnetically stirred for 4 hours to disperse the glass powder evenly; pour the mixed solution into the mold, the liqui...

Embodiment 3

[0041] It is melted into a homogeneous melt at 1450°C by melting method. The mass percent of prepared bioactive glass consists of CaO 40%, SiO 2 40%, Na 2 O 8%, P 2 o 5 12%. , all the other are with embodiment 1, and result is also similar with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com