Waste slag comprehensive recovery and utilization method for non-ferrous metals industry

A technology for industrial waste residue and non-ferrous metals, applied in the improvement of process efficiency, cement production and other directions, can solve the problems of good economic benefits, short process, low comprehensive utilization of resources, etc., and achieve the effect of simple process and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

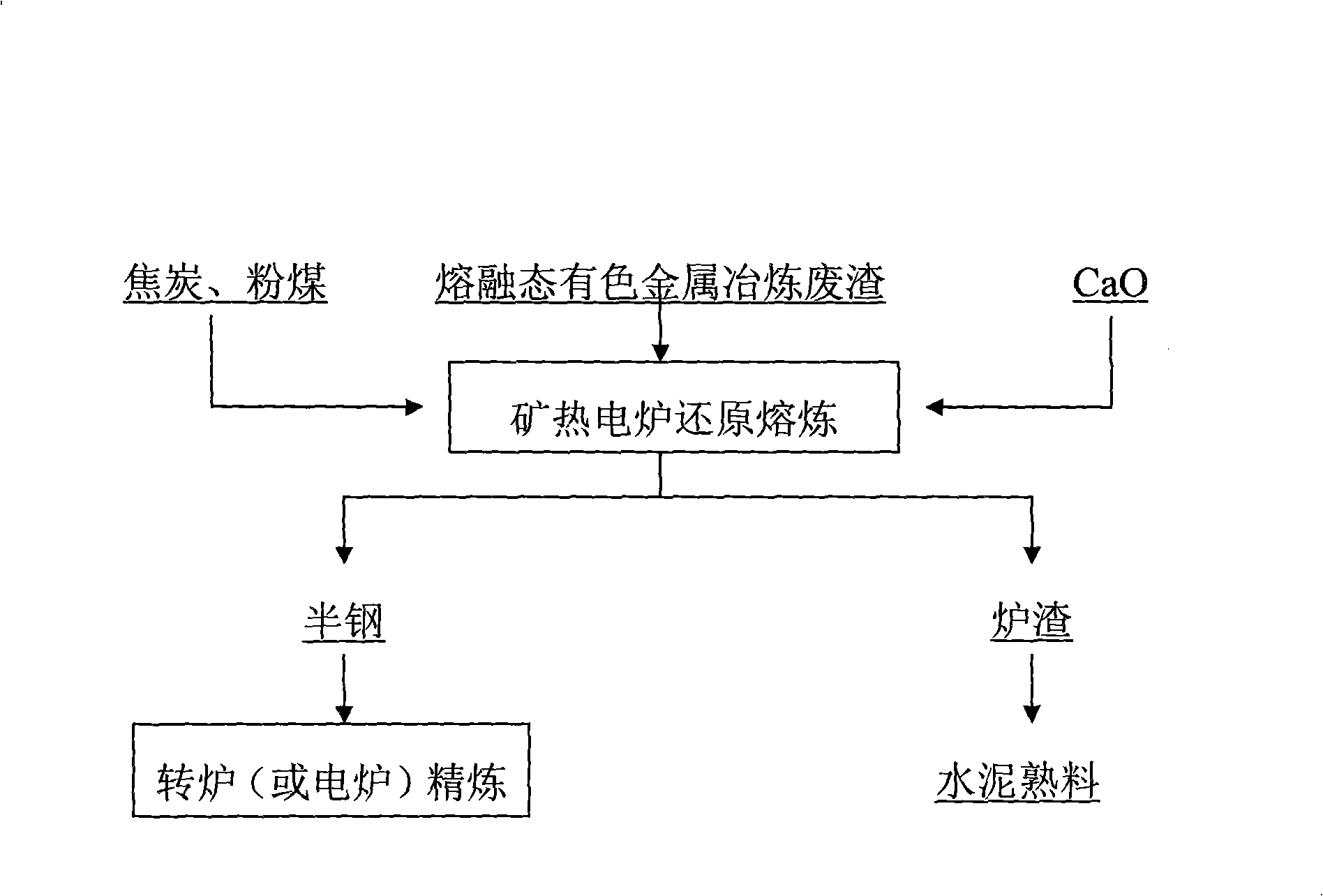

Image

Examples

Embodiment 1

[0014] Transport the molten nickel smelting waste slag directly into the submerged electric furnace, turn on the electricity and raise the temperature to 1450°C, then use compressed air to spray the mixture of coal powder and coke through the spray gun, and add CaO into the submerged electric furnace at the same time; pulverized coal The mixture with coke can reduce the iron in the slag to produce a semi-steel alloy containing more than 80% iron, and then transport the semi-steel alloy to the converter or electric furnace to smelt it into qualified molten steel; The hot slag can be used as cement clinker to be sent to the cement factory to produce high-quality cement; the weight ratio of the raw materials is, nickel pyrometallurgy waste slag:coke:coal powder:CaO=55:1:4:25.

Embodiment 2

[0016] The blast furnace slag with an iron content of more than 20% produced by pyrometallurgy in a molten state is directly transported into the submerged electric furnace, energized and heated to 1700°C, and then compressed nitrogen is used to spray the mixture of coal powder and coke through the spray gun. At the same time, CaO is added to the submerged electric furnace; the mixture of coal powder and coke reduces the iron in the slag, and the semi-steel alloy with iron content greater than 80% is obtained, and then the semi-steel alloy is transported to the converter or electric furnace, and smelted into qualified molten steel; also obtain submerged arc slag simultaneously, this submerged arc slag can send cement plant to produce high-quality cement as cement clinker; The weight ratio of described raw material is, the blast furnace slag that pyrometallurgy produces iron content more than 20%: Coke: pulverized coal: CaO=70:6:9:35.

Embodiment 3

[0018] The flash slag with an iron content of more than 20% produced by pyrometallurgy in a molten state is directly transported into the submerged electric furnace, and the temperature is raised to 1500°C with electricity, and then the mixture of pulverized coal and coke is injected through the spray gun with compressed nitrogen At the same time, CaO is added to the submerged electric furnace; the mixture of coal powder and coke reduces the iron in the slag, and the semi-steel alloy with iron content greater than 80% is obtained, and then the semi-steel alloy is transported to the converter or electric furnace, and smelted into Qualified molten steel; also obtain submerged arc slag at the same time, this submerged arc slag can be sent as cement clinker to cement factory to produce high-quality cement; Slag:coke:coal powder:CaO=60:3:6:28.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com