Aligning system, aligning method for photolithography equipment and enhancement type aligning mark

An alignment system and lithography equipment technology, applied in the field of enhanced alignment marks, can solve problems such as line shrinkage, deformation, and limited manufacturing and processing capabilities, so as to improve signal strength, reduce alignment errors, and improve resolution and the effect of alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

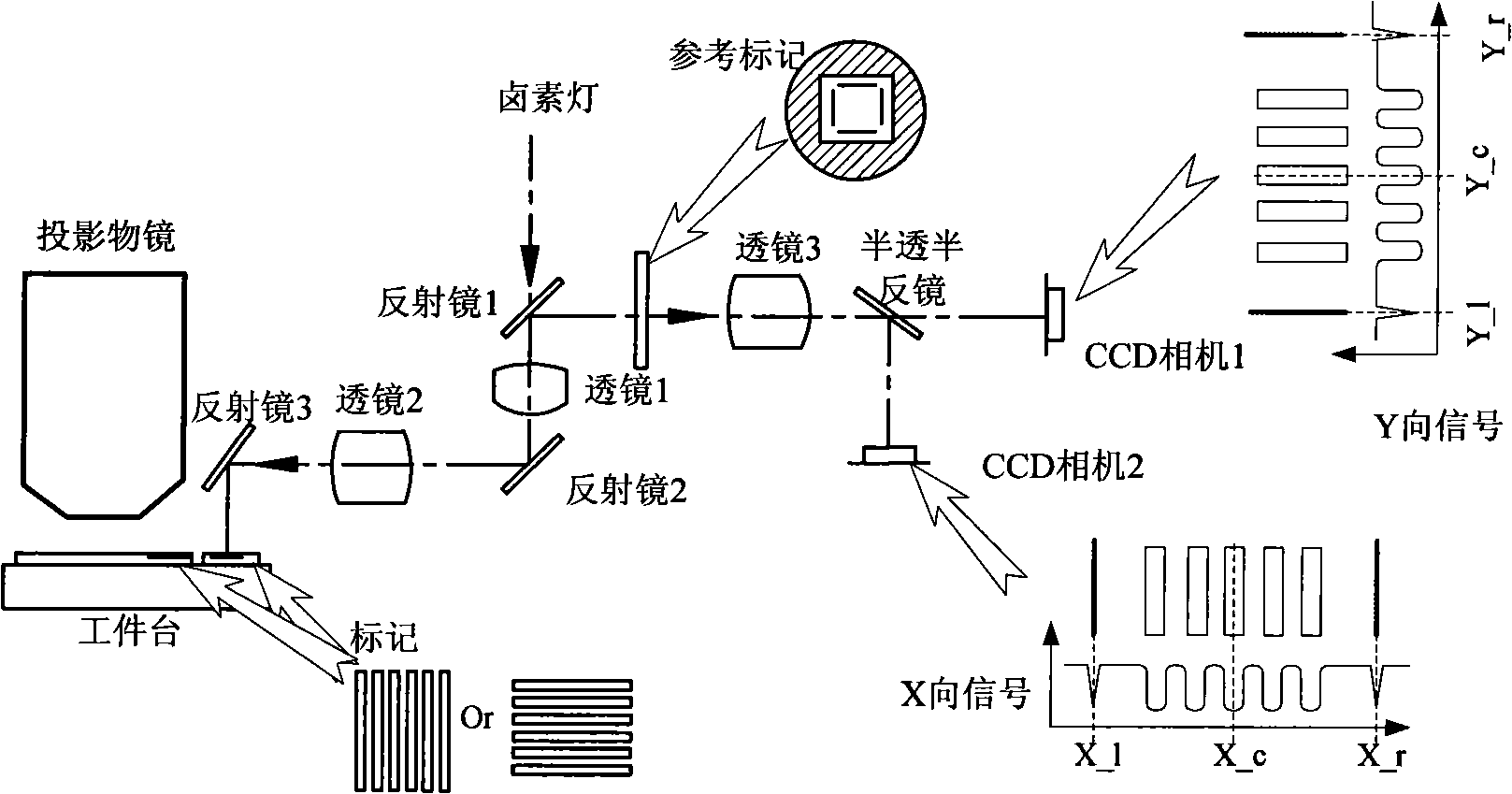

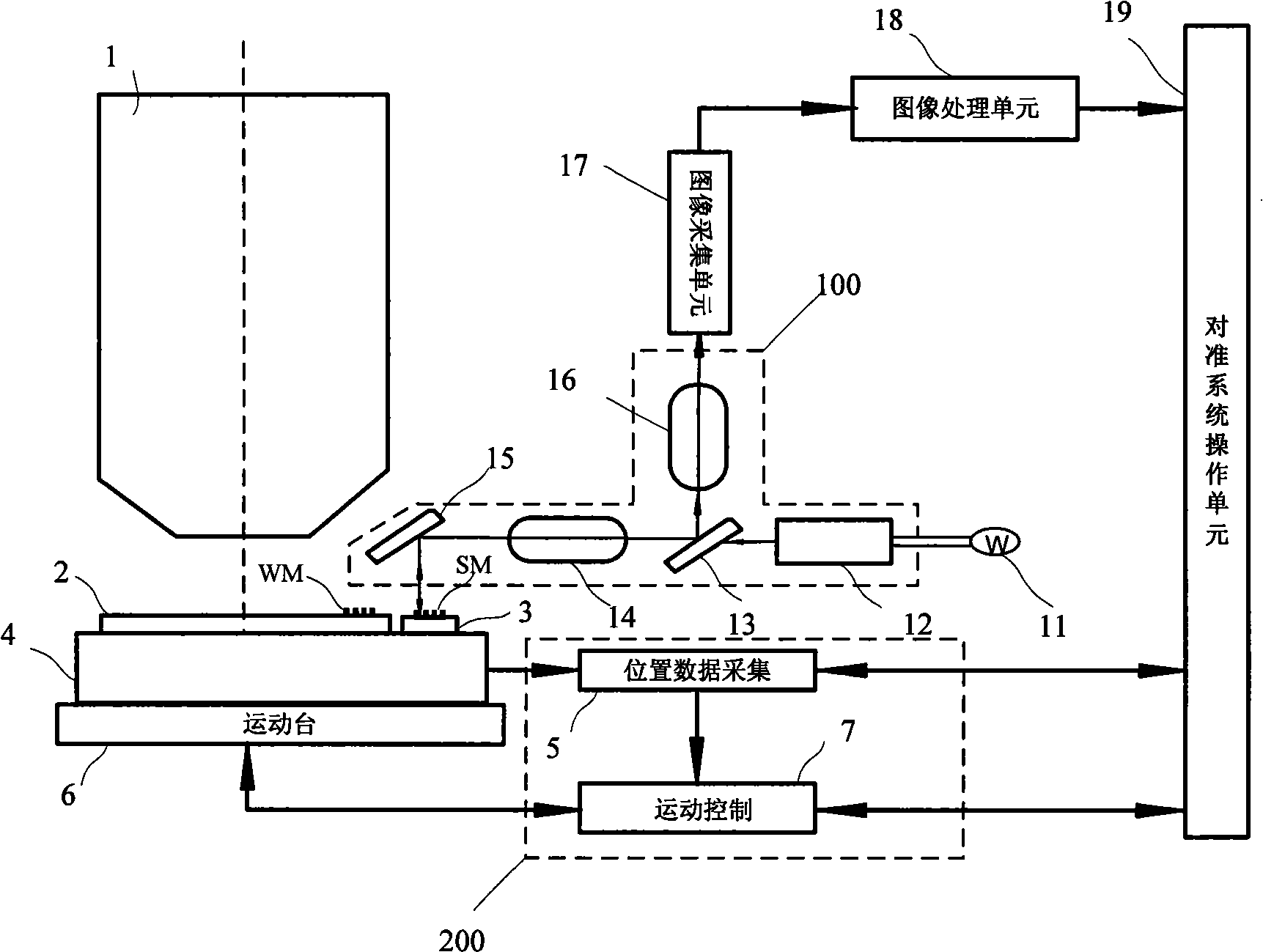

[0073] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0074] figure 2 A structural schematic diagram of an embodiment provided by the present invention, the alignment system is used to establish the coordinate position relationship between the silicon wafer alignment mark WM and the reference plate mark SM, that is, to realize the alignment between the silicon wafer and the reference plate, It includes: an alignment mark WM on the silicon wafer 2 and an alignment mark SM on the reference plate 3, a light source module 11, an illumination and imaging unit 100, an image acquisition unit 17, an image processing unit 18, an alignment An operation unit 19, and a position acquisition and motion control unit 200.

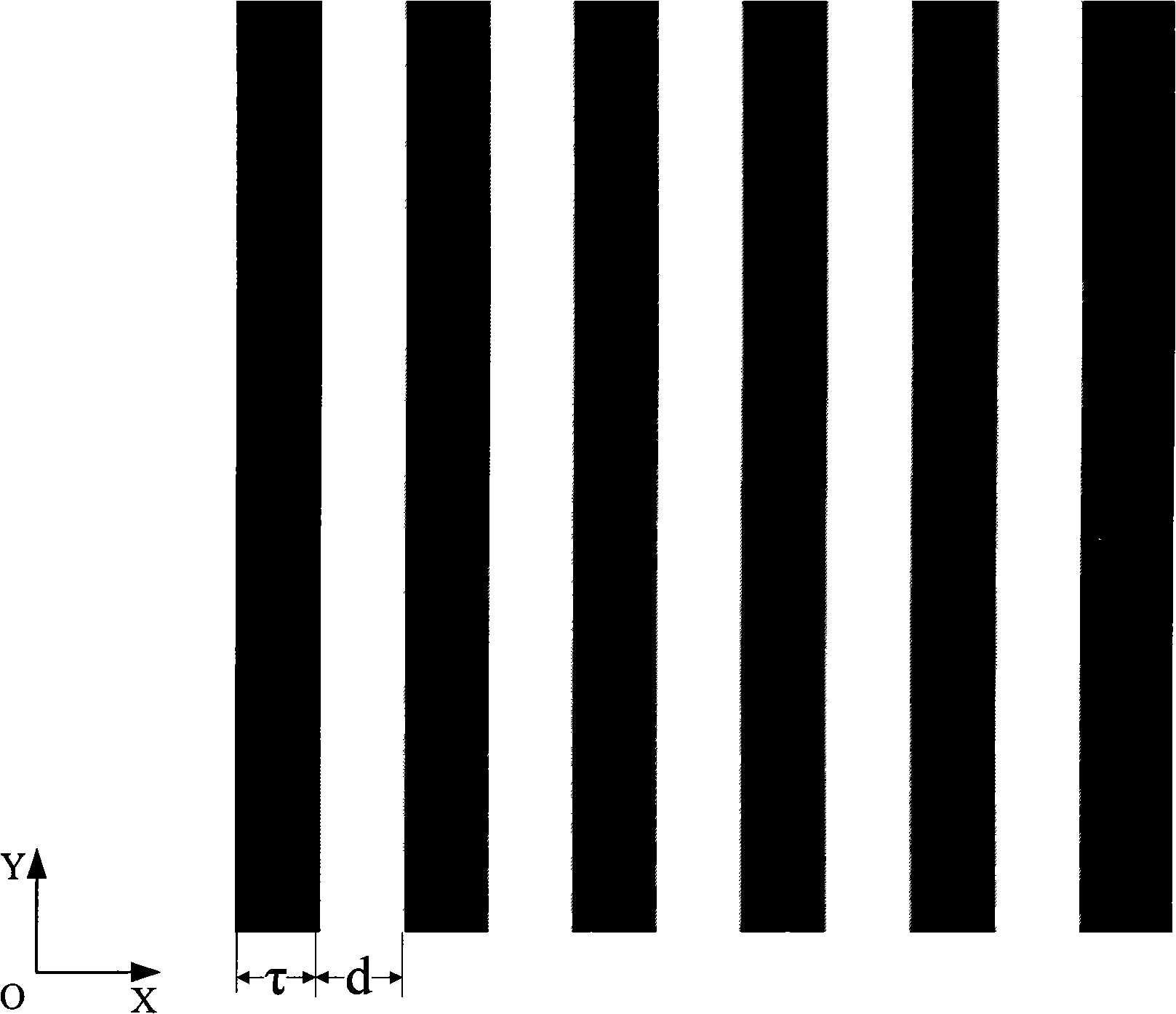

[0075] The wafer mark WM or the reference plate mark SM is composed of a group of equidistant lines, wherein the width of the lines is equal to the width of the groov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com