Titanium alloy surface high temperature oxidation corrosion resistance coatings preparation method

A high-temperature oxidation-resistant and corrosion-resistant coating technology is applied in the field of preparation of oxidation-resistant coatings on the surface of titanium alloys. It can solve problems such as poor high-temperature oxygen resistance and corrosion resistance, inapplicability to complex parts shapes, and thermal mismatch of coating film bases. Achieve the effects of high bonding strength of film base, high oxidation resistance, and blocking oxidation failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] Embodiment 1: The method for preparing a high-temperature oxidation corrosion resistant coating on the surface of titanium alloy includes a degreasing step, an oxidation step, and a water washing step, and is characterized in that the specific process of the oxidation step is:

[0014] Step 1. Fix one end of the titanium alloy part to be processed on the fixture connected to the positive output end of the pulse power supply, then put the titanium alloy part into the electrolytic tank, and ensure that all the titanium alloy parts are immersed in the In the electrolyte solution in the electrolytic cell, the electrolyte solution is an alkaline solution;

[0015] Step 2. After fixing the stainless steel electrode on the fixture connected to the negative output terminal of the pulse power supply, immerse the stainless steel electrode in the electrolyte in the electrolytic tank, and ensure that the stainless steel electrode does not contact the titanium alloy parts;

[0016] ...

specific Embodiment approach 2

[0024] Specific embodiment two: The difference between this embodiment and the high-temperature oxidation corrosion resistant coating on the surface of titanium alloy described in specific embodiment one is that the base material is TC4 alloy, and the electrolyte adopts aluminate electrolyte (20g / L- NaAlO 2 , 1g / L-Na 3 PO 4 ), in step three, the output parameters of the pulse power supply are voltage 550V, frequency 600Hz, duty cycle 8%, and duration 10min.

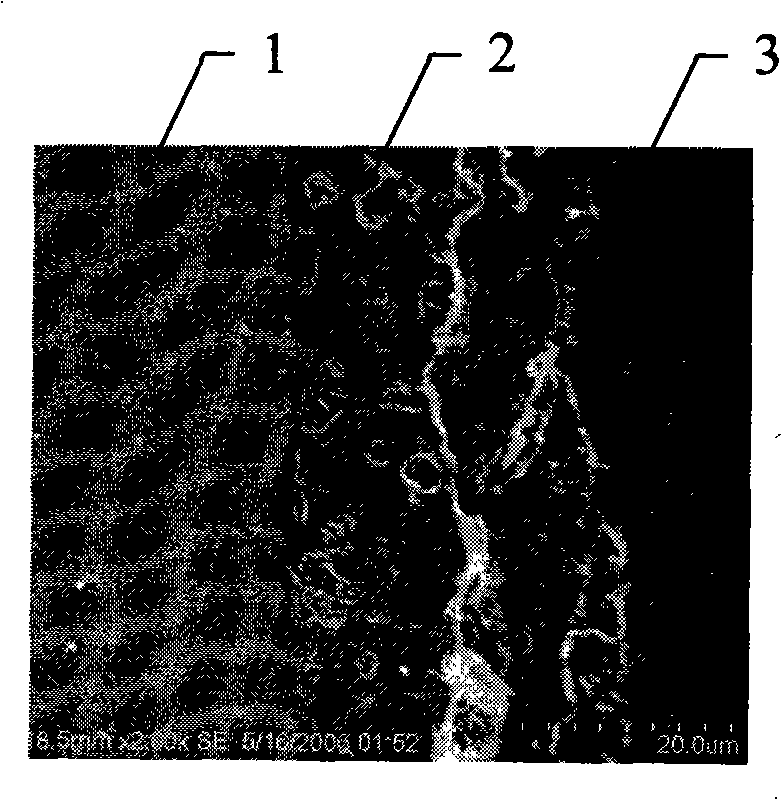

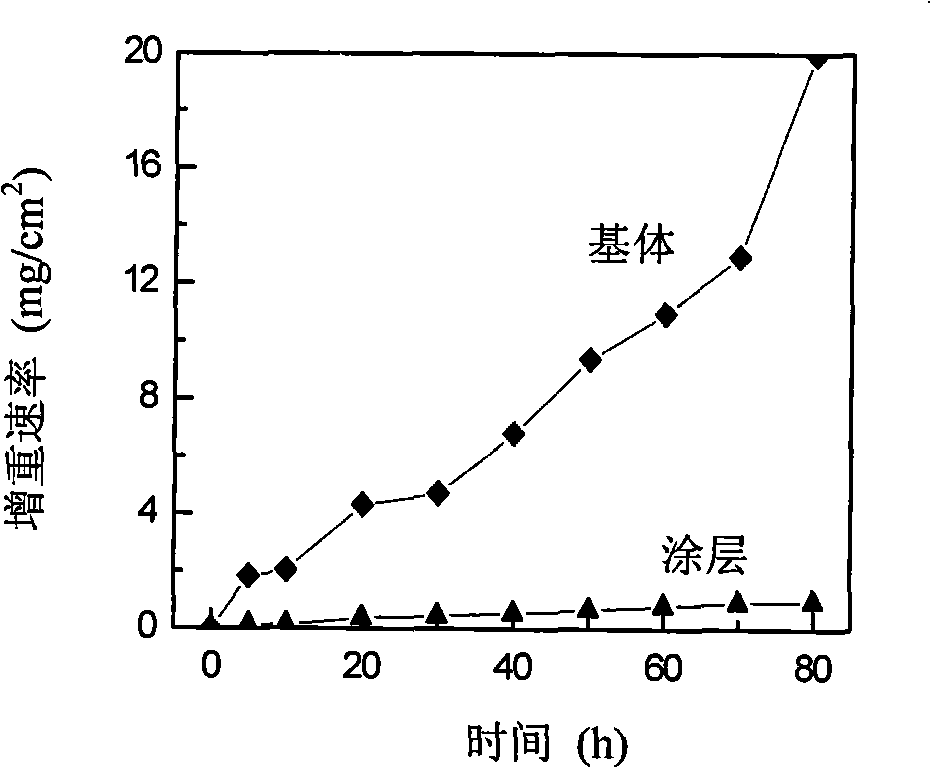

[0025] The thickness of the dense ceramic layer on the surface of the TC4 alloy obtained in this embodiment is about 12 microns, such as figure 1 As shown, the coating consists of Al 2 TiO 5 and Al 2 Ti 7 o 15 Composition, the coating exhibits good anti-oxidation protection performance. The method for preparing the high-temperature oxidation-resistant coating on the surface of titanium alloy described in this embodiment is placed in a muffle furnace for constant temperature oxidation, the constant temperature is 7...

specific Embodiment approach 3

[0026] Specific embodiment three: the difference between this embodiment and the high-temperature oxidation-corrosion-resistant coating on the surface of titanium alloy described in specific embodiment one is that the substrate is a TC4 alloy, and the electrolyte adopts a silicate electrolyte (20g / L-Na 2 SiO 3 , 4g / L-KOH, 10g / L-(NaPO 3 ) 6 ), in step three, the output parameters of the pulse power supply are voltage 500V, frequency 600Hz, duty cycle 8%, and duration 10min.

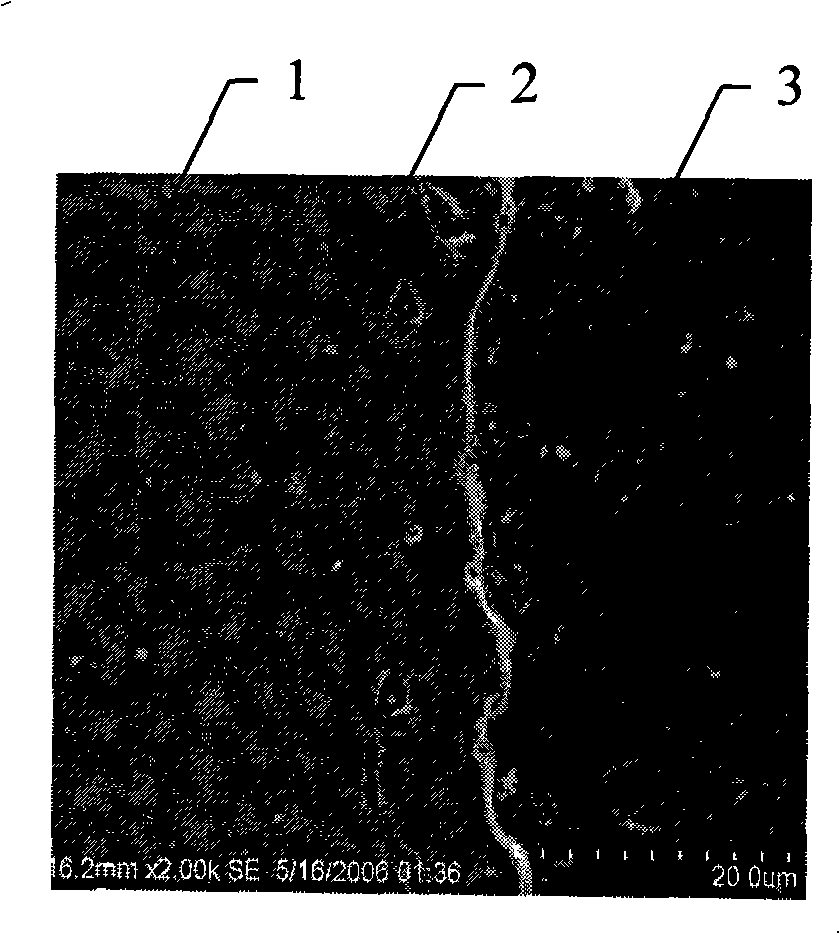

[0027] The thickness of the dense ceramic layer on the surface of the TC4 alloy obtained in this embodiment is about 10 microns, such as image 3 As shown, the coating obtained after micro-arc oxidation is composed of anatase and rutile TiO 2 Composition, rutile as the main phase. The coating exhibits good oxidation resistance. The preparation method of the titanium alloy surface anti-oxidation corrosion coating described in this embodiment is placed in a muffle furnace for constant temperature oxidat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Gain weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com