Light source device

A light source device, light source technology, applied in the direction of light source, electric light source, lighting device, etc., can solve the problems of color drift, high cost, high color rendering index, and achieve the effect of simplifying optical design and easy heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

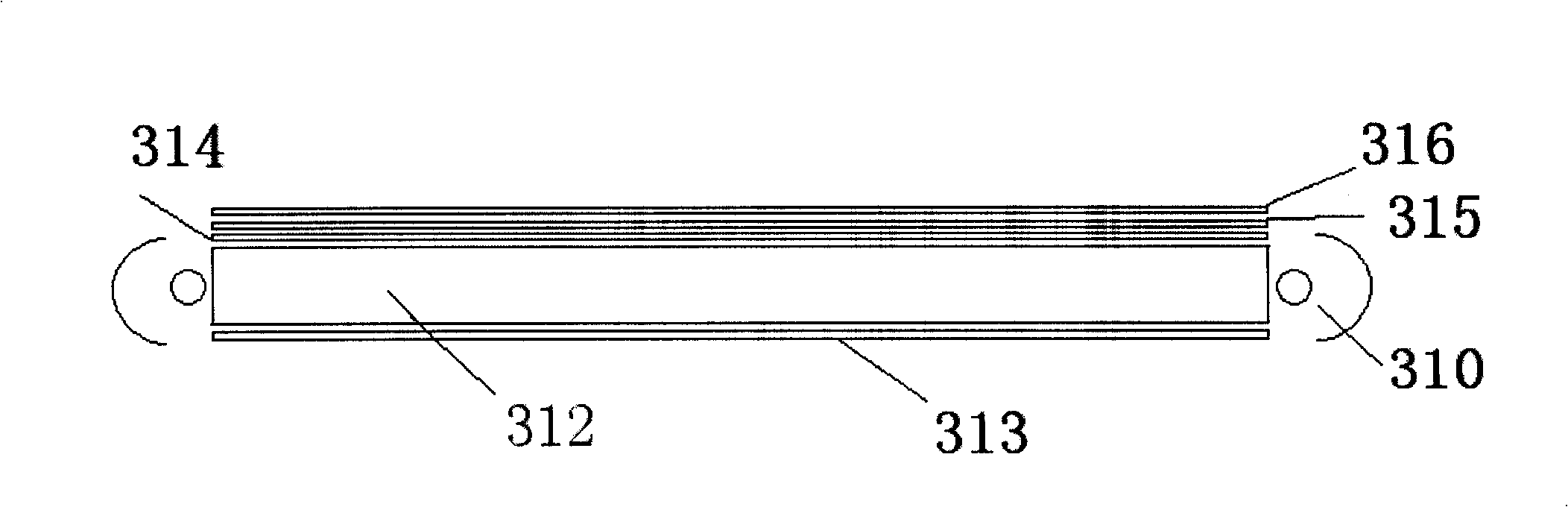

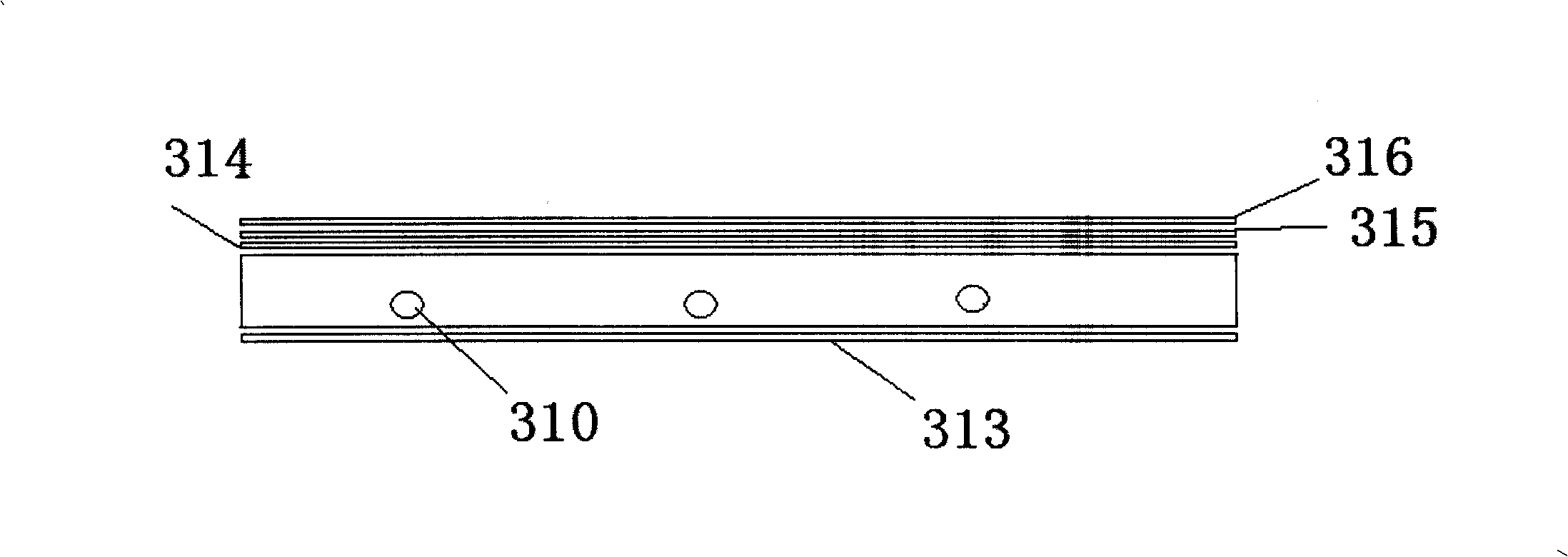

[0070] The light source device in this embodiment can adopt figure 1 Or any structure shown in 2, a blue CCFL or LED light source 310 is used, and a photoluminescent film 316 is provided.

[0071] The green luminescent material is selected as coumarin (C6) or dimethylquinacridine (dimethyquinacrodone) (MDQD) series derivatives, or a mixture of two or more luminescent materials, and the film-forming material is acrylic acid or polycarbonate Resin-like. The weight ratio of coumarin (C6) to acrylic resin (solid content) is 0.1-30%.

[0072] The red luminescent material is selected as DCM2 (4-(dicyanomethylene)-2-methyl-6-(p-dimethylaminostyryl)-4H-pyran) or DPP (diphenylpentacence), and green luminescent material such as coumarin (C6) can also be added Or dimethylquinacridine (dimethylquinacrodone) (MDQD) series derivatives, yellow light-emitting materials, etc. to improve the blue-red light conversion efficiency. The film-forming material is acrylic or polycarbonate resin. T...

Embodiment 2

[0076] The light source device in this embodiment can adopt figure 1 Or any of the structures shown in 2, a blue CCFL or LED light source 310 is used, and a photoluminescence film 316 is provided.

[0077] For the preparation of green polymer luminescent materials, P-PPV, PF8T or their derivatives, or a mixture of two or more luminescent materials are selected, and the film-forming material is acrylic or polycarbonate resin. The weight ratio of resin (solid content) is 1-99%.

[0078] The red polymer luminescent material is selected from MEH or CN-PPV, or PFT (copolyfluorene of polythiophene and polyfluorene) and its derivatives, and yellow luminescent materials such as PPV can also be used to improve the conversion efficiency of blue light to red light. The film-forming material is acrylic or polycarbonate resin. The weight ratio of luminescent material to resin (solid content) is 1-99%.

Embodiment 3

[0080] The device structure of this embodiment is as figure 1 Or 2, and principle is identical with embodiment one, two, difference is:

[0081] To prepare the green luminescent material, choose ZnS / Cu or SrGa2O4 / Eu inorganic luminescent material, or a mixture of two or more luminescent materials, and the weight ratio is 1-99% (to the solid content of the acrylic resin).

[0082] The red luminescent material is prepared from Y2O2S / Eu or SrS / Eu inorganic luminescent material, or a mixture of two or more luminescent materials, and the weight ratio is 1-99% (to the resin solid content).

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap